Punching unit for retainer gear points of car seat sliding rail

A car seat slide rail and stamping machine technology, which is applied to vehicle parts, transportation and packaging, manufacturing tools, etc., can solve the problems of inability to realize automation, inability to improve work efficiency, inability to accurately provide stamping work, etc., to achieve enhanced automated stamping degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

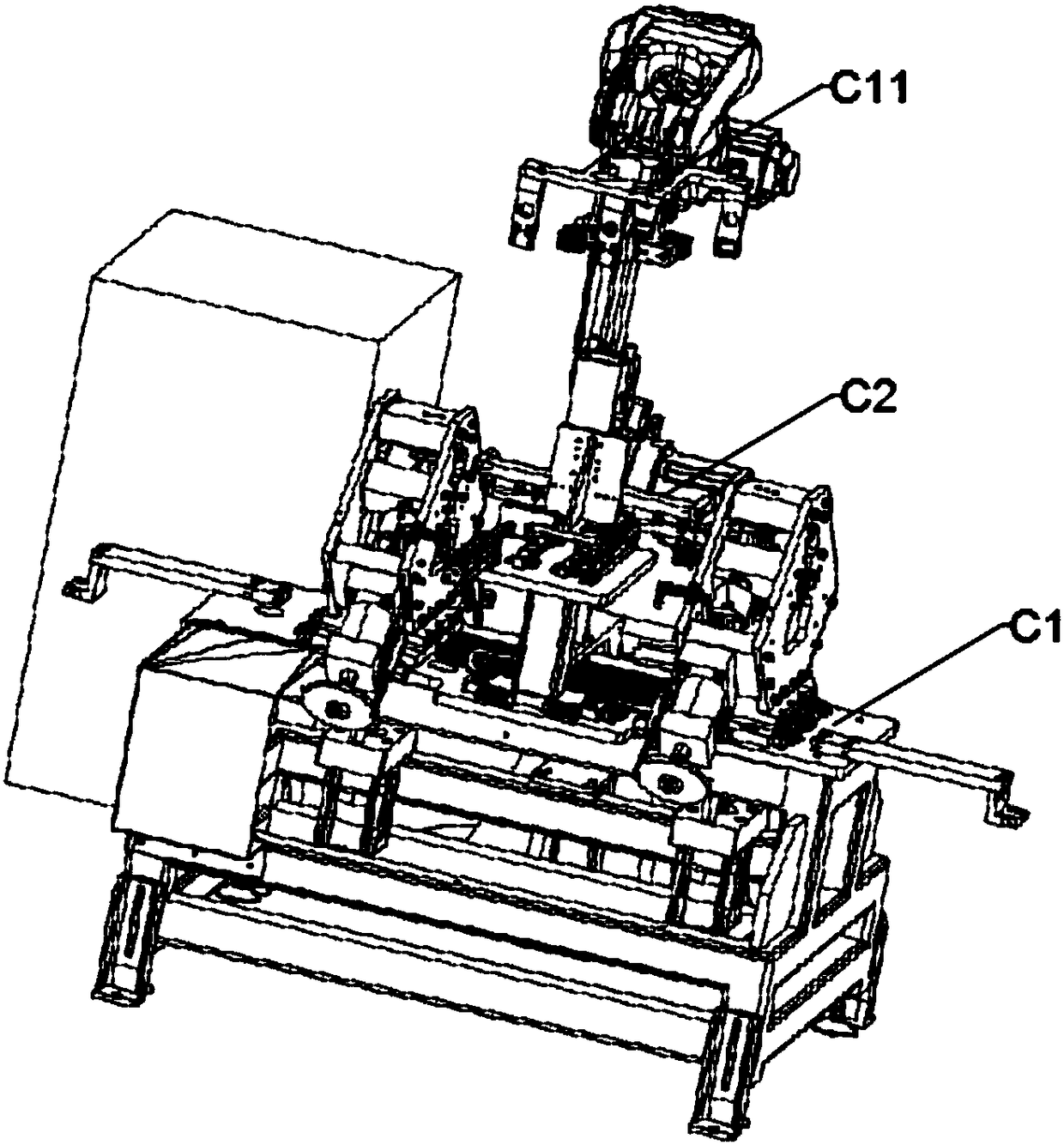

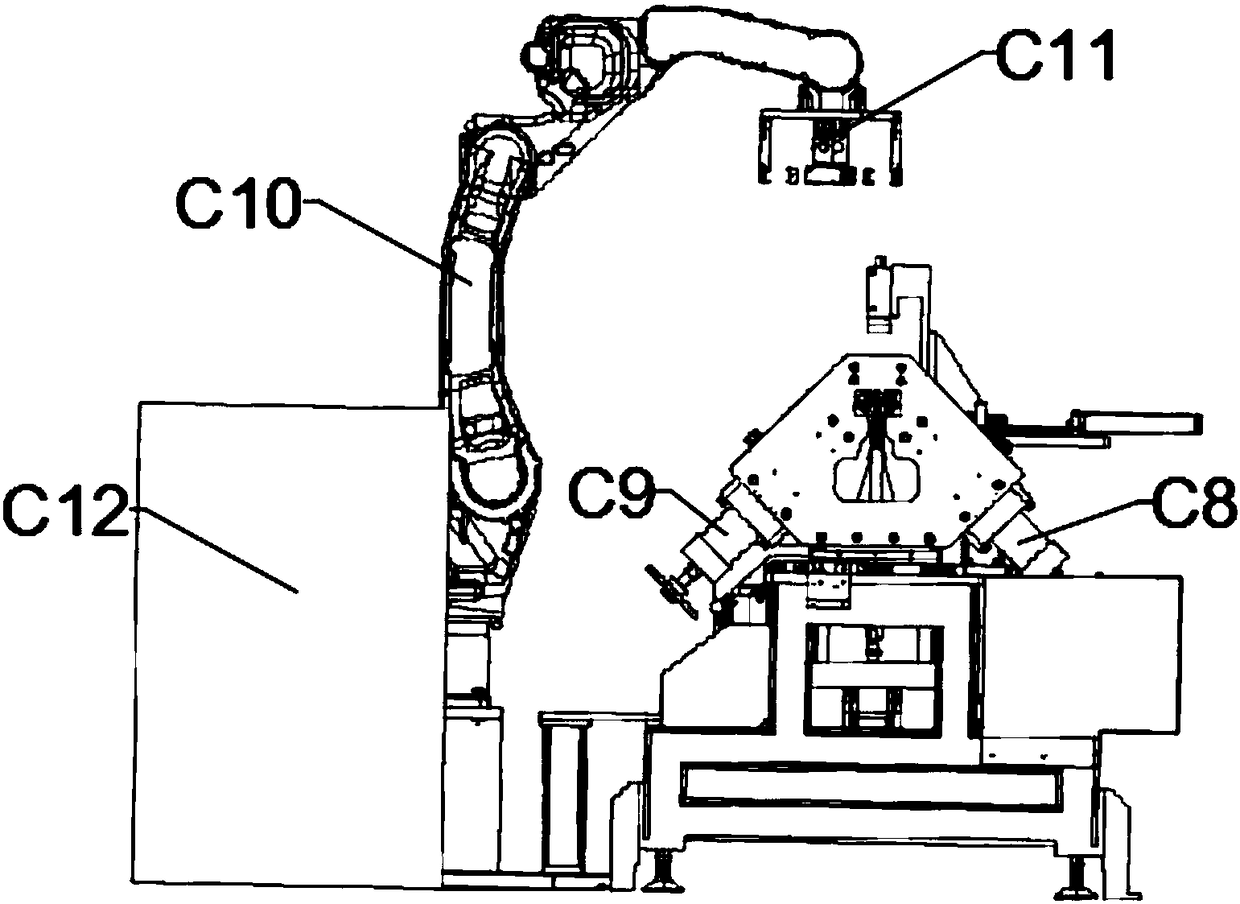

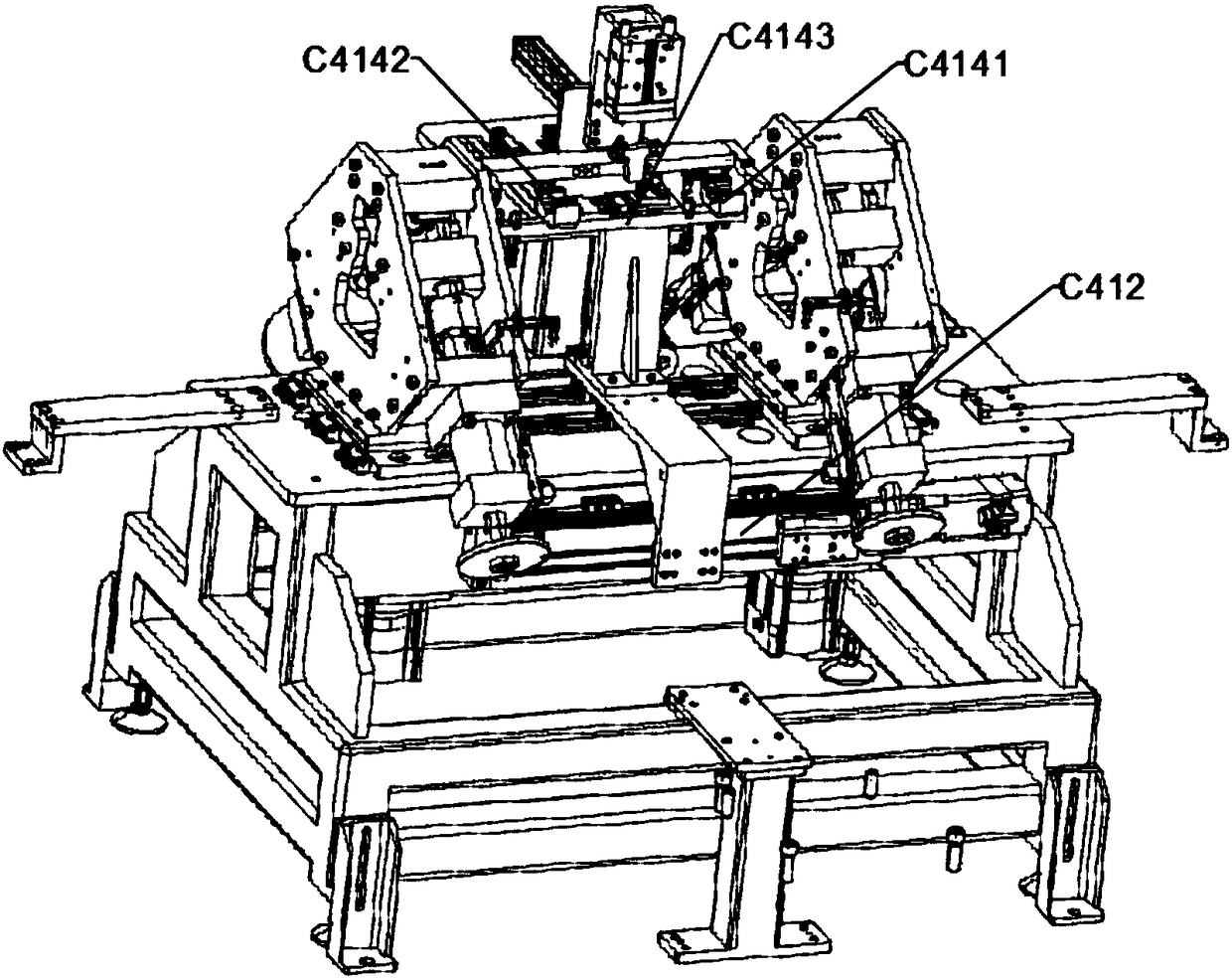

[0024] like Figure 1 to Figure 11 As shown, the present invention provides an automatic stamping system for cage gear points, including a machine base C1, on which a slide rail fixing device C2 is arranged, and the slide rail fixing device C2 includes an inner rail fixing device C3 and an outer rail pusher C4; the left and right sides of the slide rail fixing device C2 are equipped with a stamping unit C5 with the same structure, the stamping unit C5 is fixed on the stamping frame C6, the stamping frame C6 is fixed on the frame C1, and the top of the stamping frame C6 is fixed with an outer rail The profiling head C7 and the stamping unit C5 include the first stamping machine C8 and the second stamping machine C9 with the same structure, and the first stamping machine C8 and the second stamping machine C9 are perpendicular to each other; the frame C1 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com