Desulfurization flue gas treatment method

A technology for flue gas treatment and flue gas treatment system, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problem of inability to achieve flue gas system treatment, poor flue gas treatment effect, and low recovery and utilization of flue gas heat. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with accompanying drawing:

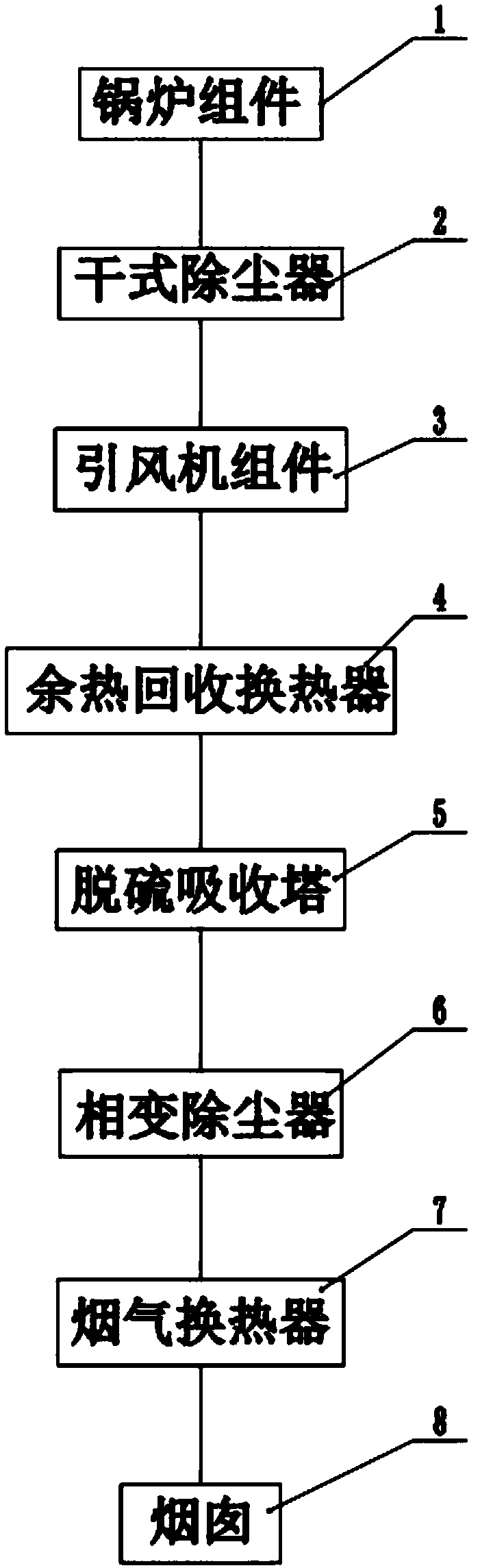

[0071] Such as figure 1 As shown, a desulfurization flue gas treatment system in this embodiment includes a boiler assembly 1, a dry dust collector 2, an induced draft fan assembly 3, a waste heat recovery heat exchanger 4, a desulfurization absorption tower 5, and a phase change dust collector connected in sequence. 6. Flue gas heat exchanger 7 and chimney 8.

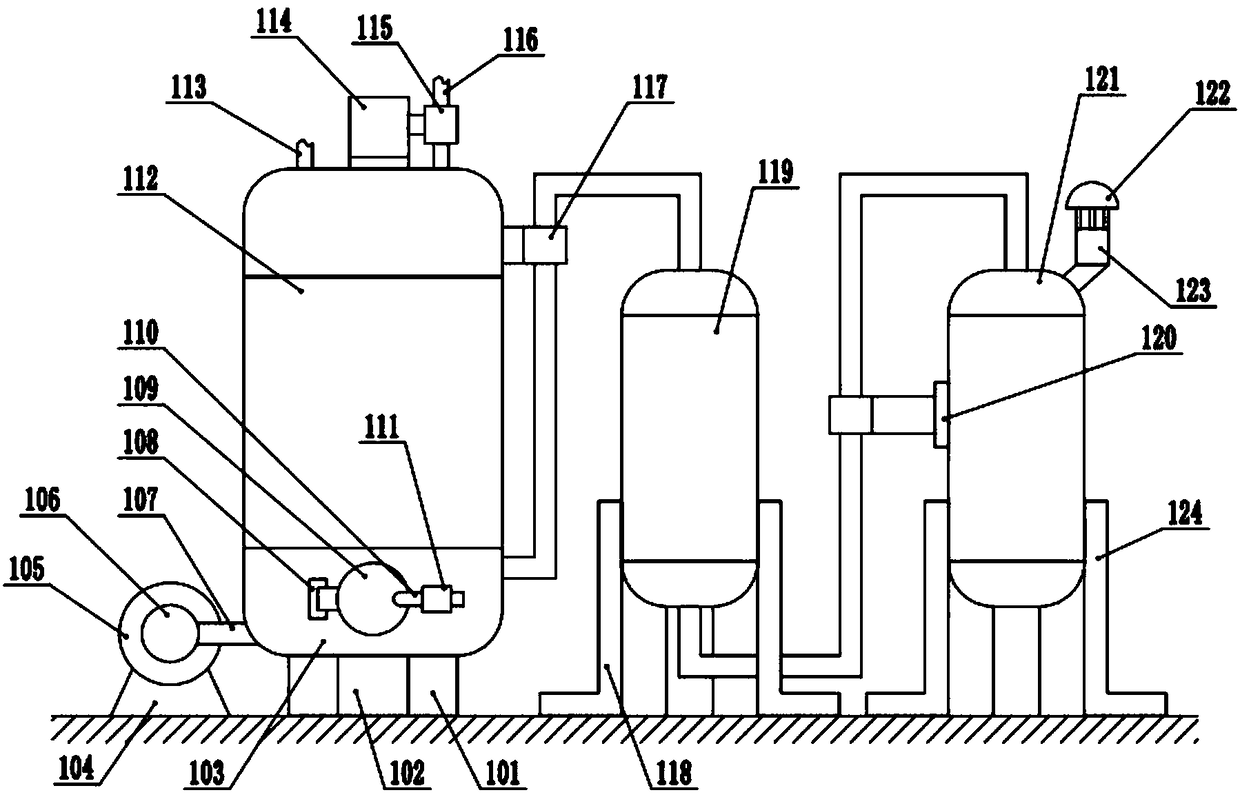

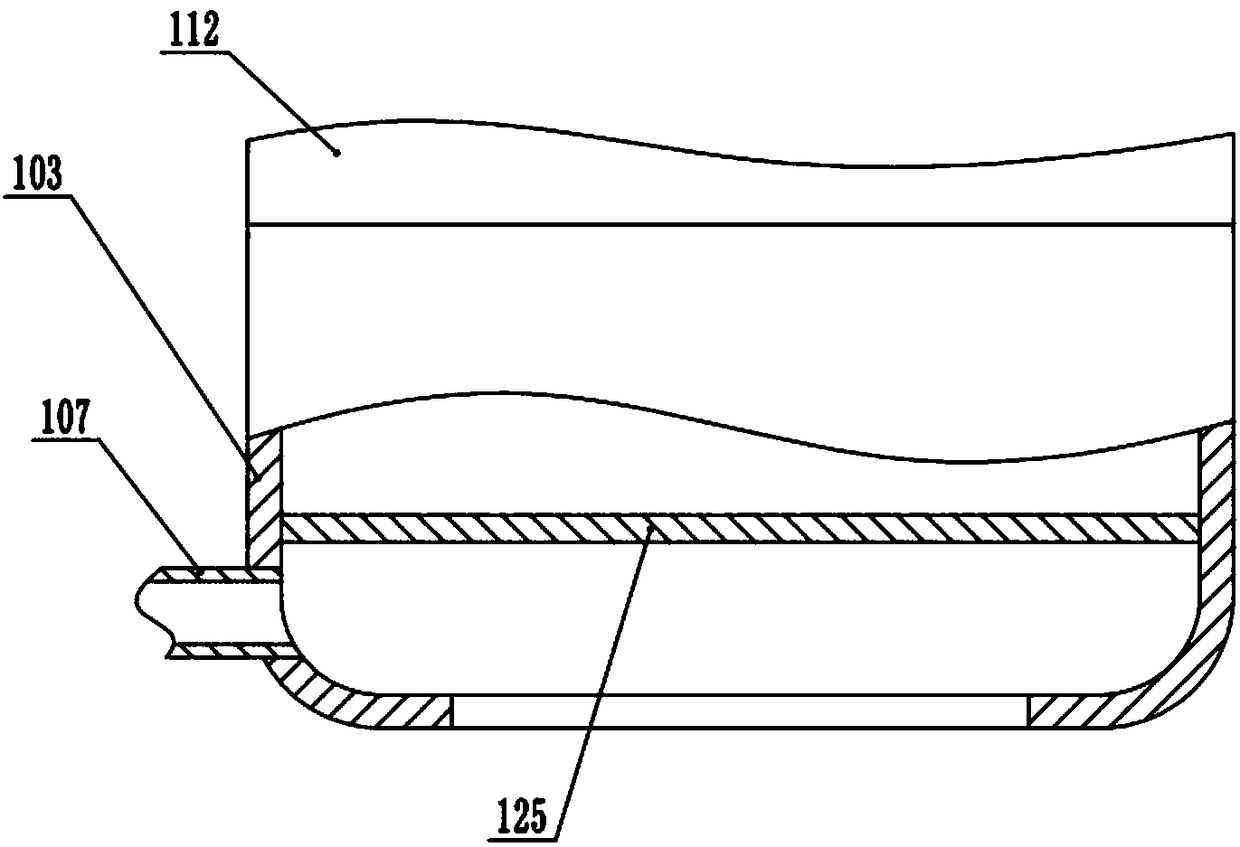

[0072] Such as Figure 2-Figure 4 As shown, the boiler assembly 1 of the present embodiment includes a slag cleaning box 101, a door 102, a boiler 103 and a motor seat 104, and the slag cleaning box 101 is equipped with a box door 102, and the slag cleaning box 101 is connected with the boiler 103, and the boiler 103 A ventilation pipe 107 is installed on the top, the ventilation pipe 107 is connected with the fan 106, the fan 106 is connected with the motor 105, the motor 105 is connected with the motor base 104,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com