Cobalt nickel sulfide/cobaltous sulfide/carbon composite material and preparation and application thereof

A carbon composite material, cobalt-nickel sulfide technology, applied in nanotechnology for materials and surface science, hybrid/electric double-layer capacitor manufacturing, electrochemical generators, etc., can solve problems such as serious energy problems, and achieve excellent biological Compatibility, regular and uniform specific surface area, inhibition of structural collapse and fragmentation and the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

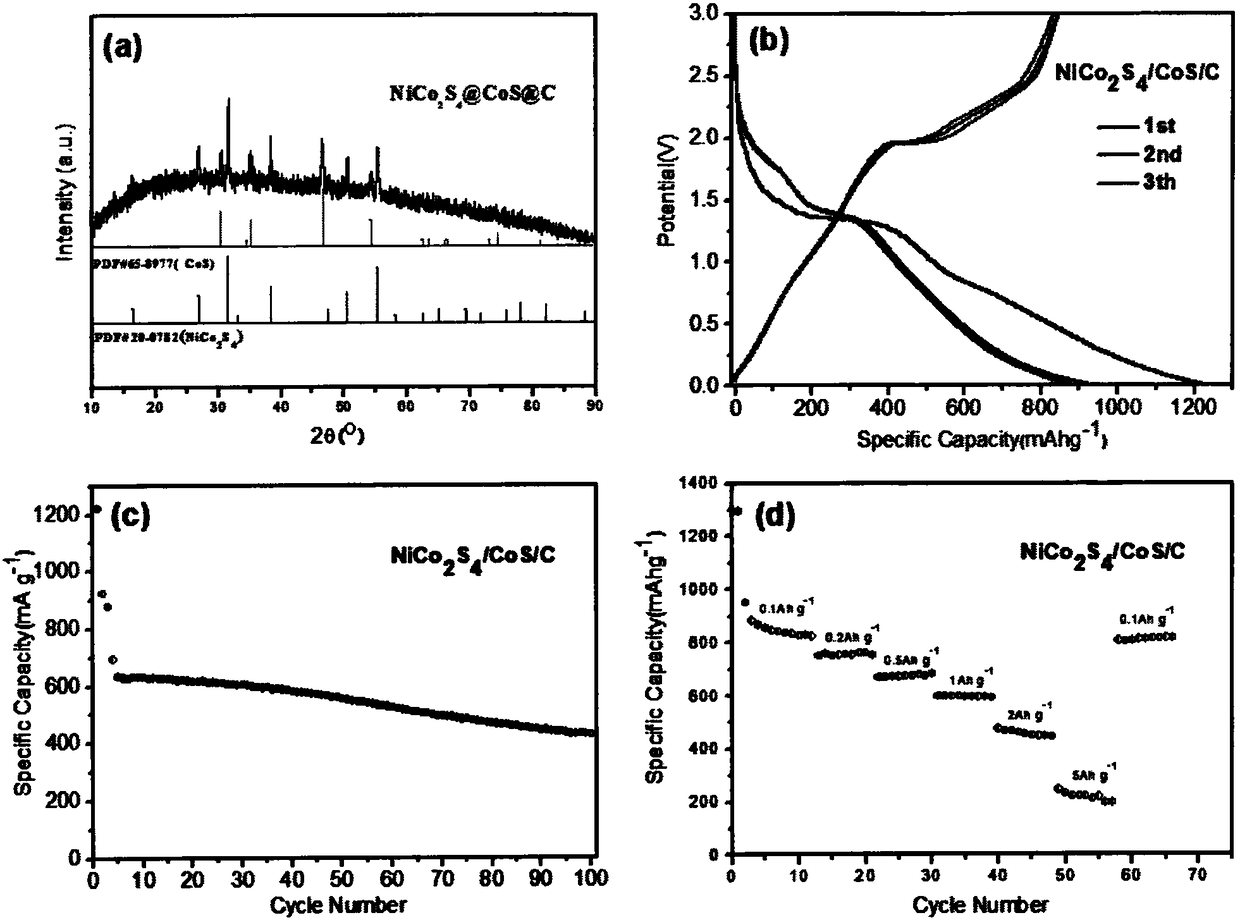

[0035] A cobalt nickel sulfide / cobalt sulfide / carbon composite material comprises cobalt nickel sulfide / cobalt sulfide nanowires and a carbon layer coated on the cobalt nickel sulfide / cobalt sulfide nanowires.

[0036] The preparation method of described cobalt nickel sulfide / cobalt sulfide / carbon composite material is:

[0037] (1) Prepare the cobalt-nickel nanowire precursor by urea co-precipitation method. The specific implementation method includes: weighing 1.16g cobalt nitrate hexahydrate, 0.59g nickel nitrate hexahydrate, 0.84g urea, uniformly dissolved in 400mL deionized water, and After reacting at 100°C for 24 hours, the precipitated product was repeatedly washed with deionized water and dried to obtain a cobalt-nickel nanowire precursor for future use.

[0038](2) Take 400 mg of the above-mentioned cobalt-nickel precursor nanowires, add them to 200 mL of deionized water, and stir continuously for 1 hour with an experimental magnetic stirring table to obtain a unifor...

Embodiment 2

[0050] (1) The nickel-cobalt nanowire precursor was prepared by urea co-precipitation method. The specific implementation method included: weighing 1.16g cobalt nitrate hexahydrate, 0.59g nickel nitrate hexahydrate, 0.84g urea, uniformly dissolved in 400mL deionized water, and placed in an oven Reaction at 100°C for 24 hours, the product precipitate was repeatedly washed with deionized water for several times, and dried to obtain the cobalt-nickel nanowire precursor, which was set aside;

[0051] (2) Take 400 mg of the above-mentioned cobalt-nickel precursor nanowires, add them to 200 mL of deionized water, and continuously stir for 1 hour with an experimental magnetic stirring table to obtain a uniform dispersion, which is the cobalt-nickel nanowire precursor dispersion;

[0052] (3) Take by weighing 315.2mg buffer reagent Tris hydrochloride, add it to the above-mentioned dispersion liquid, then configure NaOH with a pH of 13, add the above-mentioned dispersion liquid dropwise...

Embodiment 3

[0056] (1) The nickel-cobalt nanowire precursor was prepared by urea co-precipitation method. The specific implementation method included: weighing 1.16g cobalt nitrate hexahydrate, 0.59g nickel nitrate hexahydrate, 0.84g urea, uniformly dissolved in 400mL deionized water, and placed in an oven Reaction at 100°C for 24 hours, the product precipitate was repeatedly washed with deionized water for several times, and dried to obtain the cobalt-nickel nanowire precursor, which was set aside;

[0057] (2) Take 200 mg of the above-mentioned cobalt-nickel precursor nanowires, add them to 200 mL of deionized water, and continuously stir for 1 hour with an experimental magnetic stirring table to obtain a uniform dispersion, which is the cobalt-nickel nanowire precursor dispersion;

[0058] (3) Take by weighing 315.2mg buffer reagent Tris hydrochloride, add it to the above-mentioned dispersion liquid, then configure NaOH with a pH of 13, add the above-mentioned dispersion liquid dropwise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com