Intelligent power module aluminum base plate and plate dividing method thereof, positioning device and air conditioner

A technology of intelligent power modules and positioning devices, which is applied in the field of manufacturing, can solve problems such as damage, burrs easily caused by board splitting, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0031] The invention provides a splitting method of an aluminum substrate of an intelligent power module, which is used to solve the problem that the traditional splitting method of an aluminum substrate of an intelligent power module is easy to damage the insulating layer in the middle of the aluminum substrate and that the aluminum substrate of an intelligent power module formed after splitting is difficult to maintain In the subsequent printing process, it plays a positioning role, thereby increasing the processing difficulty of the smart power module, which leads to the problem of low production efficiency of the smart power module.

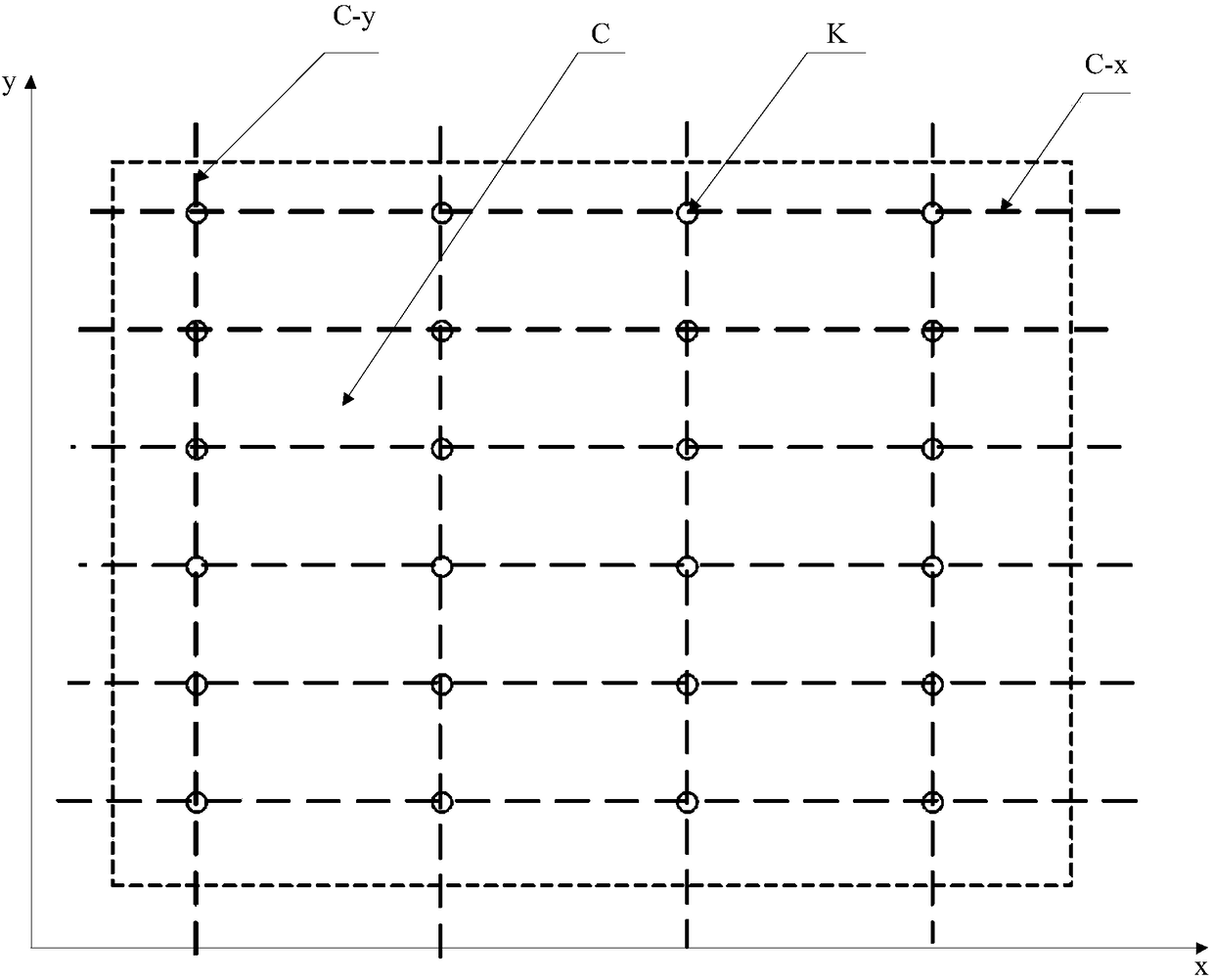

[0032] refer to figure 1 , in one embodiment, the method for dividing the aluminum substrate of the intelligent power module includes the following steps:

[0033] S10, setting a nu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com