Touch screen laser splicing pattern structure and its etching wiring method

An etching line, touch screen technology, applied in instruments, computing, electrical and digital data processing, etc., can solve the problems of limited distance and short circuit of laser once, avoid splicing deviation, ensure splicing accuracy, and save etching wiring time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

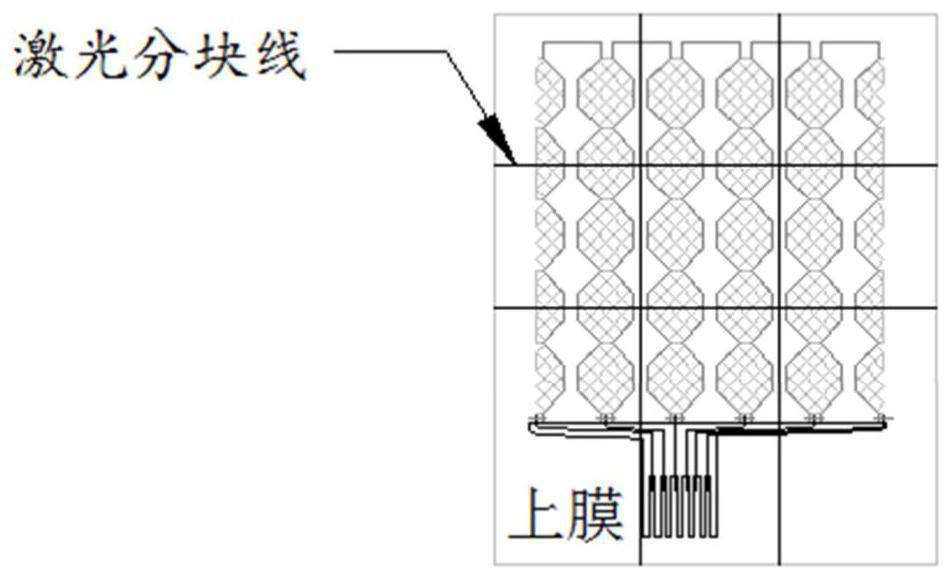

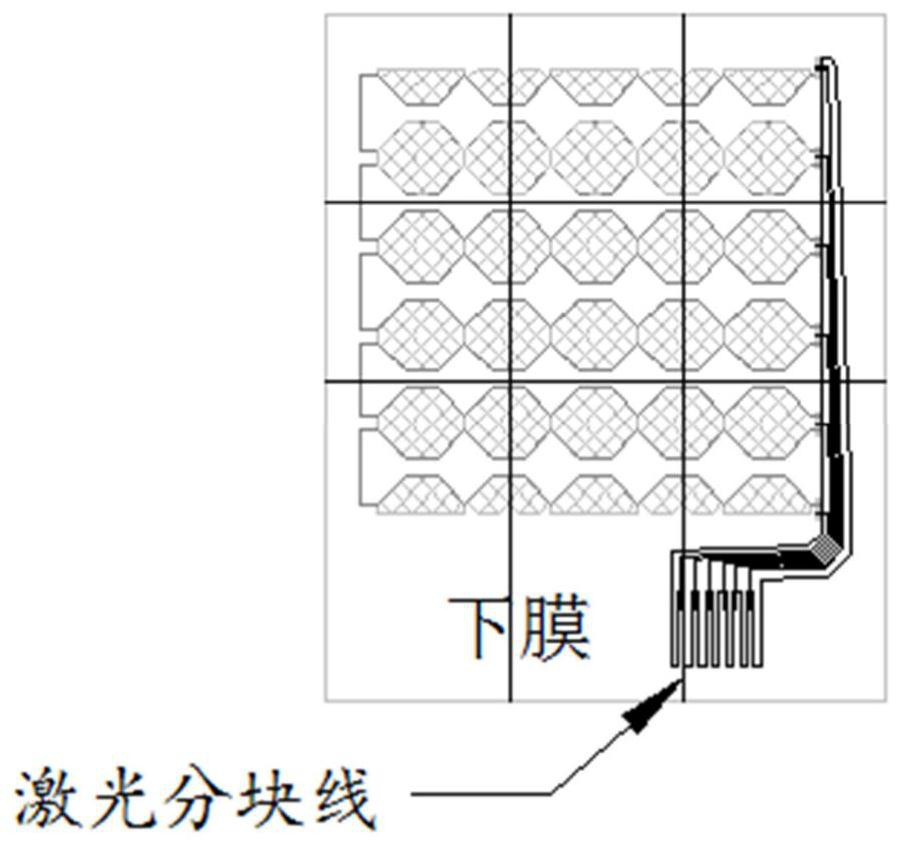

[0031] Such as image 3 with Figure 4 As shown, this embodiment relates to a touch screen laser splicing pattern structure, including a first etching line 1 and a second etching line 2 adjacent to it, and the first etching line 1 and the second etching line 2 pass through the first right angle at the splicing point The bending structure is connected; the first right-angle bending structure is a first open rectangle 5, including two parallel etching lines and an etching line perpendicular to and connected to the two parallel etching lines;

[0032] The extension of the first etching line 1 and the second etching line 2 intersects at an intersection angle α.

[0033] This embodiment also includes a third etching line 3 and a fourth etching line 4 adjacent to it, the third etching line 3 and the fourth etching line 4 are connected by a second right-angle bending structure at the joint; the second right-angle The bent structure is a second open rectangle 6, including two parall...

Embodiment 2

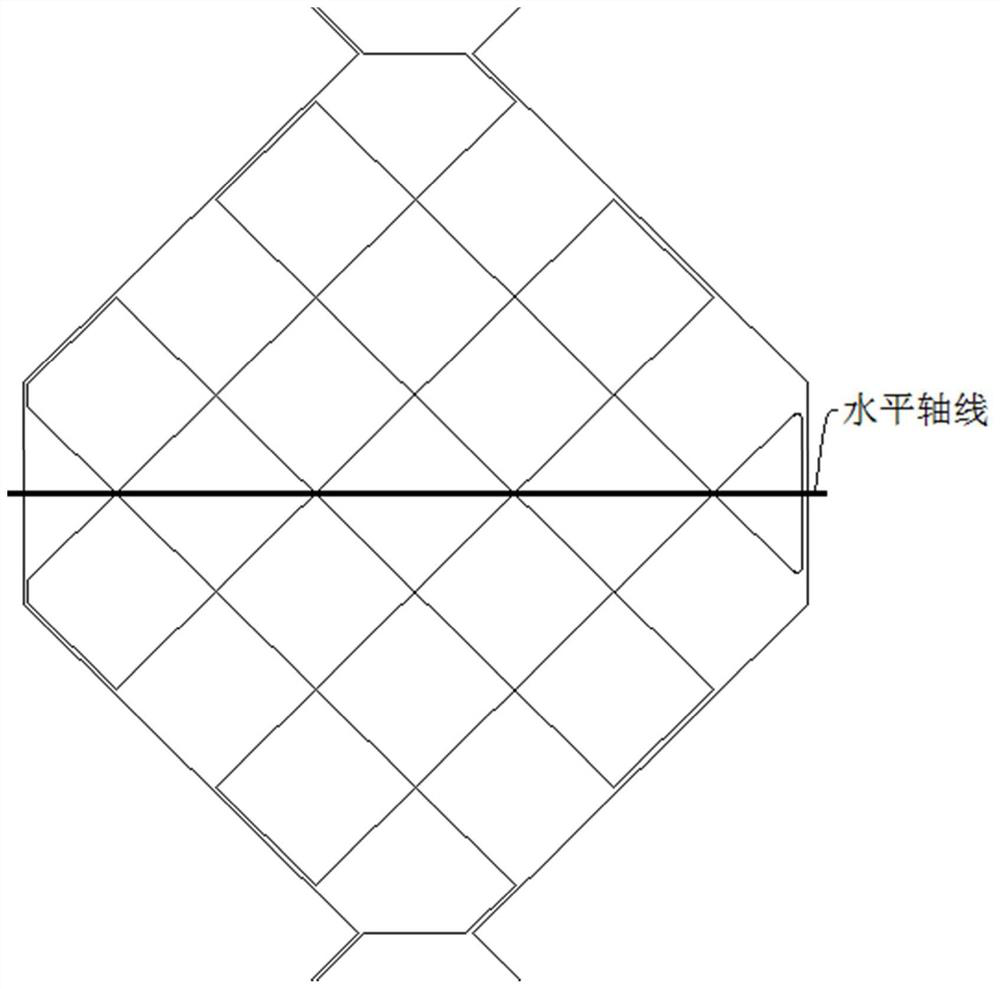

[0040] Such as Figure 5 As shown, this embodiment relates to a touch screen laser splicing pattern structure, including a first etching line 1 and a second etching line 2 adjacent to it, and the first etching line 1 and the second etching line 2 pass through the first right angle at the splicing point The bending structure is connected; the first right-angle bending structure is a first open rectangle 5, including two parallel etching lines and an etching line perpendicular to and connected to the two parallel etching lines;

[0041] The extension of the first etching line 1 and the second etching line 2 intersects at an intersection angle α.

[0042] This embodiment also includes a third etching line 3 and a fourth etching line 4 adjacent to it, the third etching line 3 and the fourth etching line 4 are connected by a second right-angle bending structure at the joint; the second right-angle The bent structure is a second open rectangle 6, including two parallel etching line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com