Splicing structure of artificial board press cross beam

A panel press and beam technology, which is applied in the splicing structure field of wood-based panel press beams, can solve the problems of high processing difficulty, poor splicing accuracy, and difficult installation, so as to reduce processing difficulty and cost, ensure splicing accuracy, The effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are easy to understand, and the present invention is further illustrated in connection with the specific illustration.

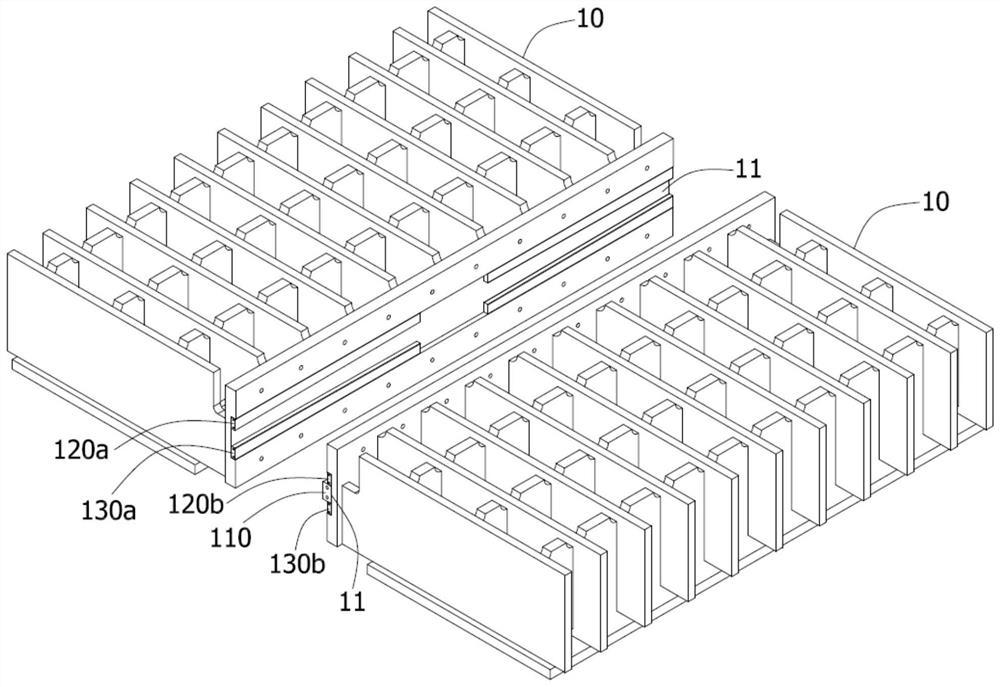

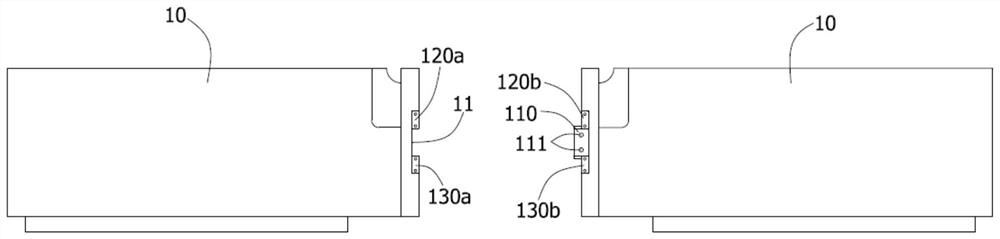

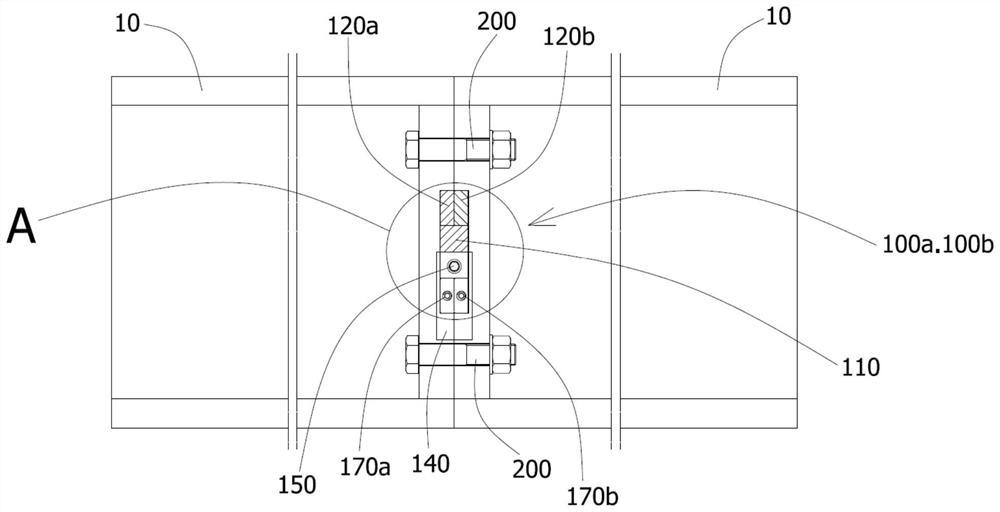

[0029] See Figure 1 to 6 The figure is given in the figure is a splicing structure of a human board transverse beam, including 锲 key assemblies 100a, 100b, and several bolt assemblies 200.

[0030] The 锲 key assemblies 100a, 100b are symmetrically mounted between the bond grooves 11 formed between the adjacent two-stage case-shaped beam 10 and located on the left and right side of the keyway 11, which is used to adjust the adjacent monomer box. The relative height between the beam 10. The plurality of bolt assemblies 200 are spaced between adjacent two-segment box beams 10 for fixing adjacent two-piece chain beams 10.

[0031] The 锲 key assemblies 100a, 100b each include a middle diagonal key 110, the left, and the upper right diagonal bonds 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com