Multi-angle adjustable device for testing sample simultaneously bearing tensile and shear forces

A test device and adjustable technology, applied in the direction of measuring device, strength characteristics, and using a stable shear force to test the strength of materials, etc., can solve problems affecting mechanical properties and achieve comprehensive effects on mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

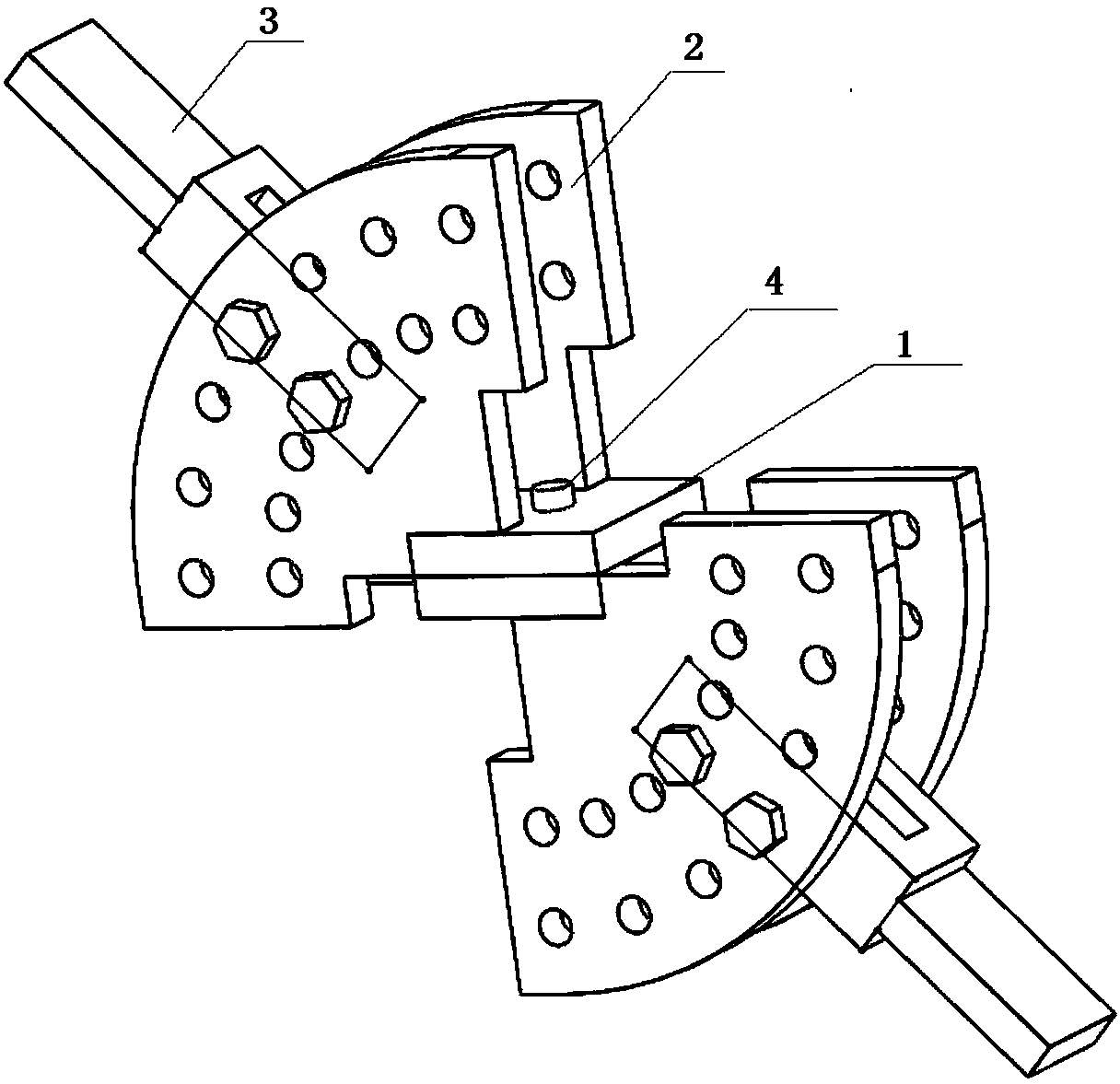

[0024] A multi-angle adjustable sample test device that simultaneously bears tensile and shear forces consists of a pair of fastening loading devices, each fastening loading device includes: connecting fastening parts and loading splints 3, connecting fastening parts It is divided into a connecting plate 2 and a fastening plate 1. There is a sample hole in the middle of the fastening plate 1. The loading splint 3 is movably connected with the connecting plate 2 so that the loading splint 3 points to the centroid 5 of the sample. The loading splint 3 can be connected with the Changes in the connection position of plate 2 change the angle relative to the specimen. The fastening plate 1 is welded to the connection plate 2.

[0025] The sample is fastened and connected to the fastening plate 1 through the sample hole in the middle of the two fastening plates 1 .

[0026] A positioning component is arranged on the connecting plate 2 .

[0027] The positioning parts are positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com