Gap-adjustable grate plate for cooling machine

A gap and grate technology, applied in the field of adjustable gap cooler grate plate, can solve the problem of non-adjustable ventilation gaps, achieve the effect of reducing spare parts specifications, reducing production costs, and broadening market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

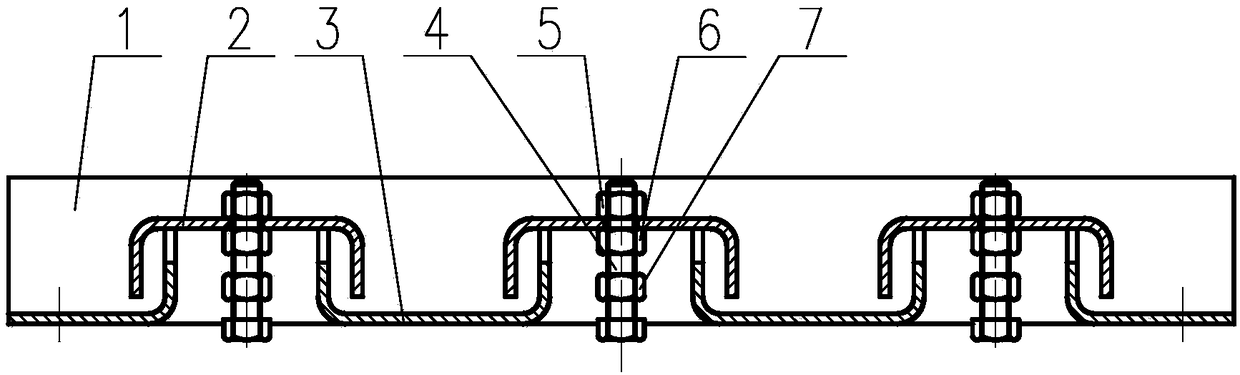

[0017] Reference figure 1 , The preferred embodiment 1 of the present invention provides a grate board for an adjustable gap cooler, which includes a grate board body 1, and also includes a plurality of fixed plates 3 and a moving plate 2, the fixed plates 3 are arranged at intervals on the same horizontal plane and fixed on On the grate board body 1, the moving plates 2 are sequentially arranged between the adjacent fixed plates 3, and the width of the moving plate 2 is greater than the distance between two adjacent fixed plates 3, and the moving plate 2 is fixed to its two sides. A ventilation gap is formed between the plates 3, and the movable plate is fixed on the adjusting mechanism and can be moved up and down through the adjusting mechanism.

[0018] Specifically, the adjusting mechanism includes an adjusting bolt 4 and a fixing nut 7 that cooperate with each other, and the fixing nut 7 is fixedly connected to the wall panel body 1, and the adjusting bolt 4 is provided with...

Embodiment 2

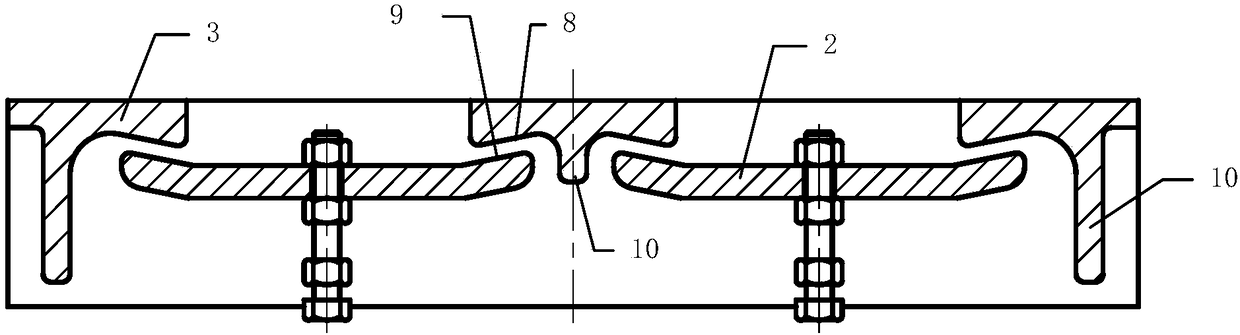

[0022] Reference figure 2 The preferred embodiment 2 of the present invention provides an adjustable gap cooler grate plate. The difference from embodiment 1 is that the fixed plate 3 is arranged above the moving plate 2, and the fixed plate 3 is provided with vertical For the downward protrusion 10, the height of the protrusion on the fixing plate on both sides of the wall plate body is greater than the height of the protrusion on the fixing plate in the middle of the wall plate body.

[0023] The lower side of the fixed plate on both sides of the protrusion 10 is a fixed inclined surface 8. The height of the fixed inclined surface 8 near the protrusion is higher than the height of the side away from the protrusion. The movable inclined surface 9 forms a ventilation gap with the fixed inclined surface 8, and the movable inclined surface 9 is an inclined surface with a high outer side and a low inner side. The ventilation slit of the specific structure formed in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com