Pressing cap type non-metallic hydraulic anchor

A non-metallic, hydraulic anchor technology, used in wellbore/well components, earthwork drilling, etc., can solve problems such as poor anchoring effect, waste of materials, and failure to achieve the expected effect, so as to improve the anchoring effect, Material saving and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

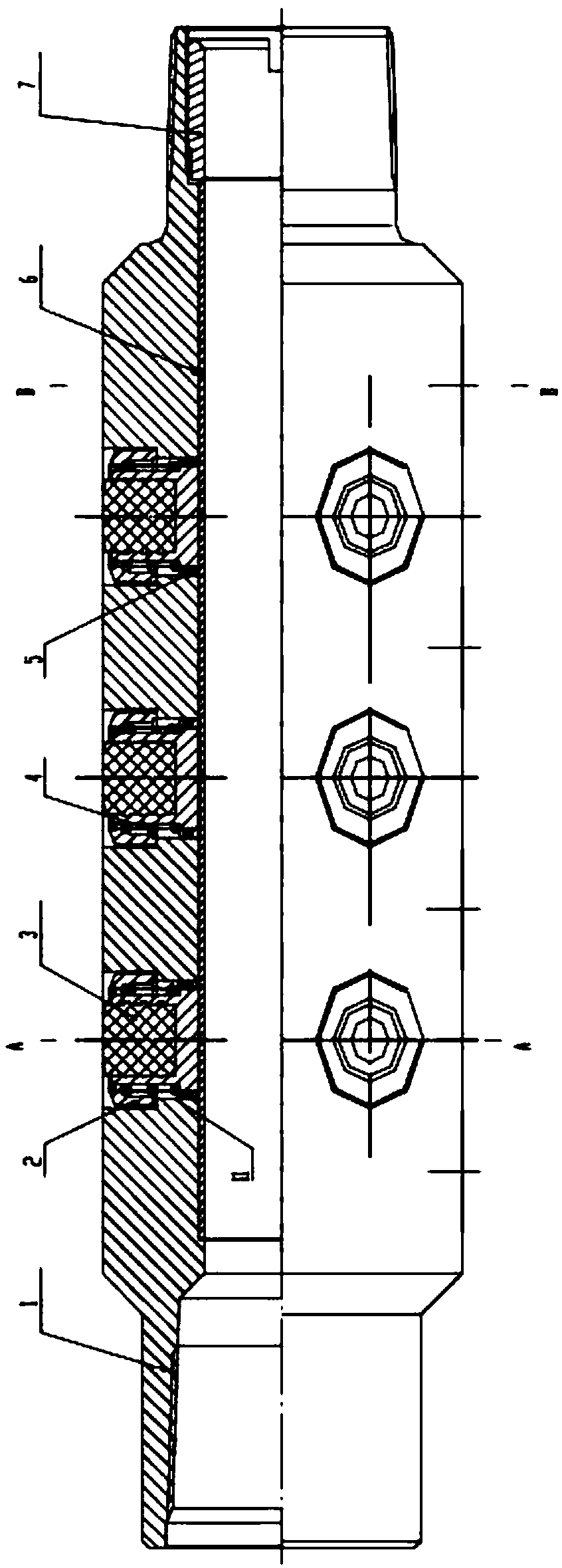

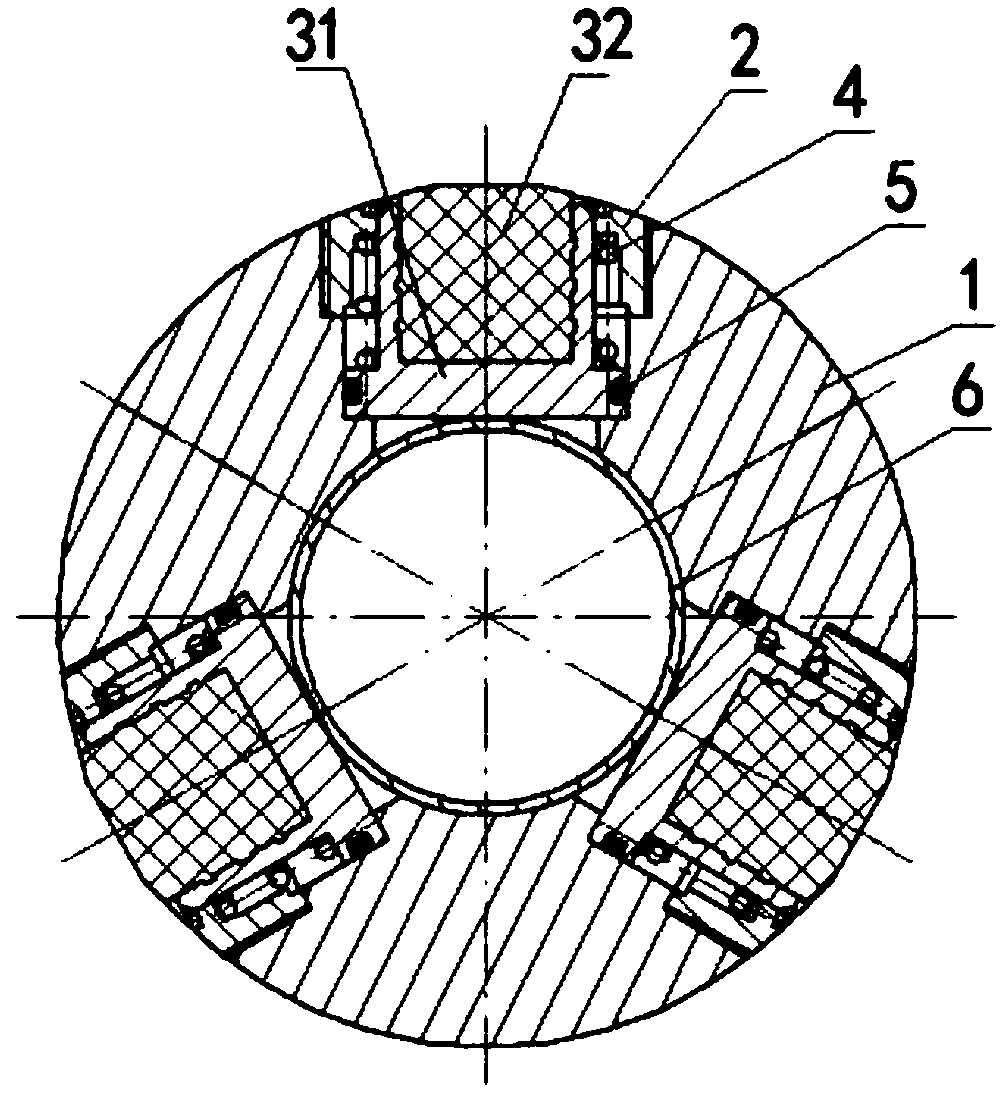

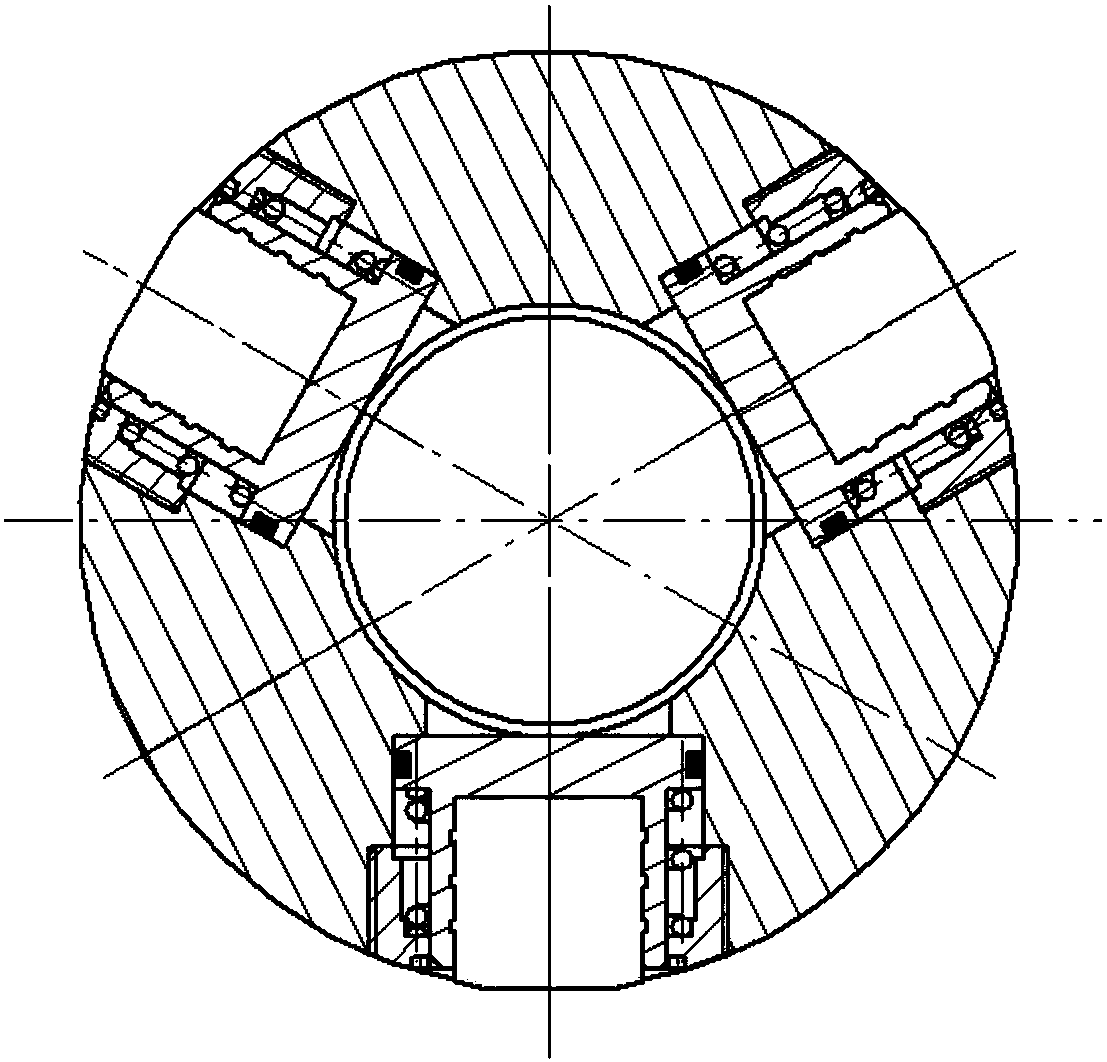

[0019] Such as Figure 1-3 Shown is the structural representation of the pressure cap type non-metallic hydraulic anchor of the present invention. The cap-type non-metallic hydraulic anchor includes an anchor body 1 , a fluke hole 11 , a non-metal fluke 3 , a cap 2 , a spring 4 , a sealing ring 5 , a sand control pipe 6 , and a cap 7 . On the anchor body 1, there are 21 anchor fluke holes 11 distributed radially and evenly. A non-metal fluke 3 is arranged in each fluke hole 11 . A sealing ring 5 is embedded in the outer circular sealing groove of each non-metallic fluke 3 . A spring 4 is provided at the step of each non-metallic fluke 3, on which a pressing cap 2 is installed. A sand control pipe 6 is arranged inside the anchor body 1, and the end is fastened with a cap 7. A sand control structure is set inside the anchor body 1 to prevent the sand particles in the well from entering the anchor fluke hole 11, thereby affecting the recovery of the anchor fluke 3, and prolon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com