Environment-friendly dismantling method based on electric heating method crushing technology

An electrothermal method and technology, applied in building maintenance, construction, building construction, etc., can solve problems such as uncertainty and danger, making loud noises, and easy to cause injuries, etc., to achieve short preparation time, reduce construction personnel and Environmental hazards, easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The green demolition method based on the electrothermal crushing technology, the pre-construction preparation includes technical preparation, material preparation and equipment preparation. The steps of the demolition method are as follows: first, through the preparation process, mark the replacement bearing points required for the replacement process at the demolition site, The second is the replacement process: install and fix the prepared replacement columns at the bearing point, connect the electrodes of the replacement columns with the remote control device through wires, and the third is the heating process: add heat around all the columns to be removed. The closed electric furnace is installed and heated at the same time. The fourth is the dismantling process: the concrete is stripped through the heating process, the internal steel frame is softened and chiseled off, all closed electric furnaces and personnel are evacuated, and the electric heating of the replaceme...

Embodiment 2

[0044] According to the green demolition method based on electrothermal method crushing technology described in embodiment 1, described preparation process comprises as follows:

[0045] (1) Technical preparation: According to the requirements of the original architectural drawings and calculation documents, it is known that the floor height of the main structure on the ground is 3.6m. The reinforcements are all HPB235 grade steel bars, the concrete grade columns are C30, the concrete grades in the beams and slabs are all C25, and the stress reinforcements in the roof and floor of the independent foundation are all HRB335 grade steel bars. Calculate the position and quantity of the alternative bearing points, and the vertical concentration of the columns The load is calculated as follows:

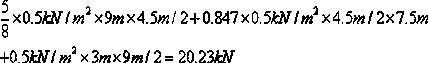

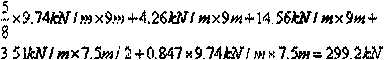

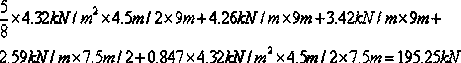

[0046] Under vertical permanent load:

[0047] 5th floor:

[0048] 5th floor side column axis = slab-transmitted longitudinal main beam load + longitudinal main beam self-weight + parapet...

Embodiment 3

[0073] According to the green demolition method based on electrothermal crushing technology described in Embodiment 1-2, the replacement process includes the following: first, according to the pre-marked bearing point position, fix the prefabricated sulfur mortar replacement column at 1m on the side of the column to be removed , and then connect the support formwork with the upper and lower floors, pour the prepared sulfur mortar on the upper and lower column heads of the replacement column, remove the formwork after curing for 24 hours, and complete the replacement and reinforcement. Drill holes at the upper and lower column heads, pour the prepared sulfur mortar into the holes and pre-embed resistance wires with an output power of 2KW.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com