Method of producing single-layer reticulated shell and rigid joint thereof

A technology of single-layer reticulated shell and manufacturing method, which is applied to manufacturing tools, building structures, casting and molding equipment, etc. The effect of reduced technical proficiency requirements and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

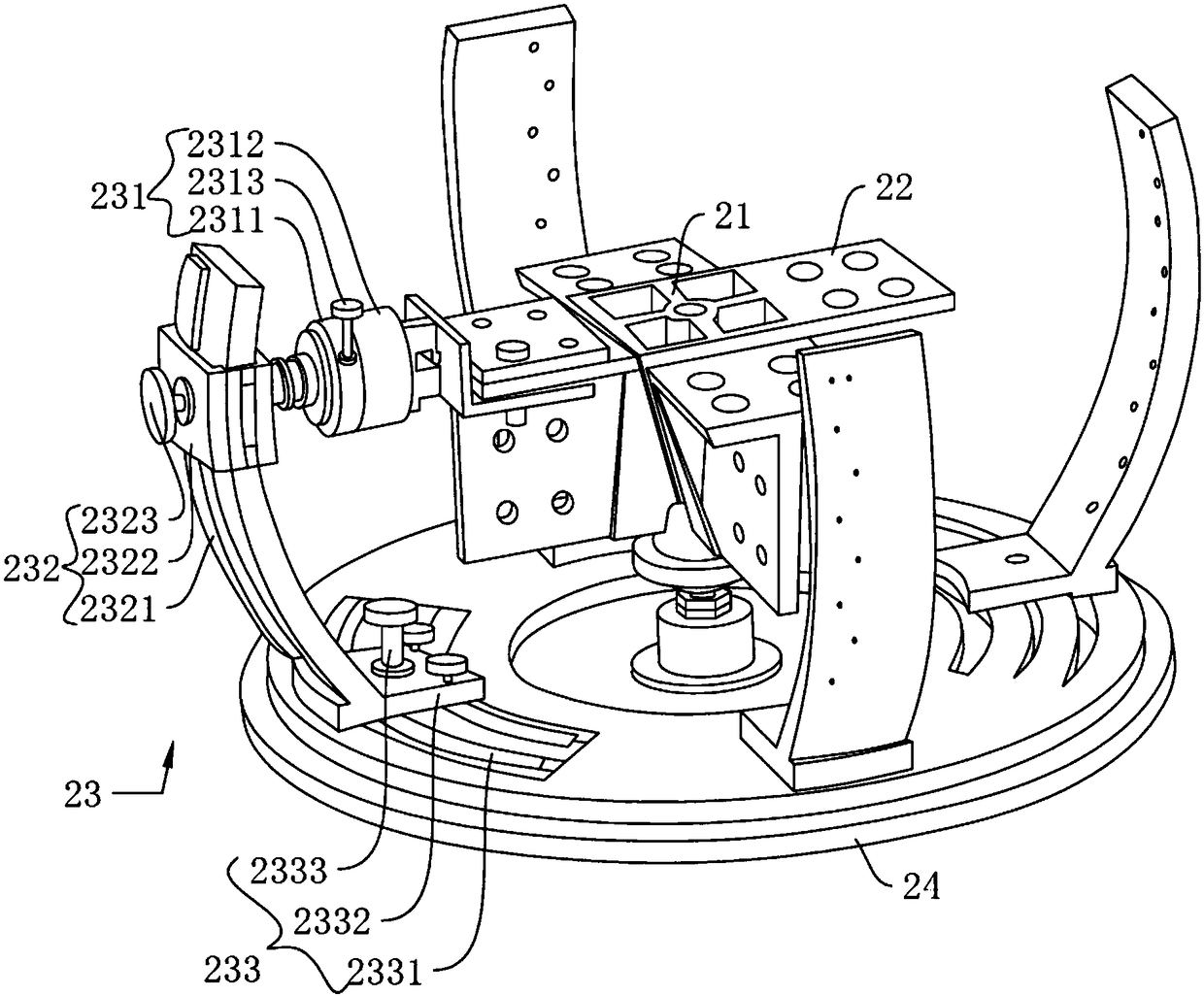

[0036] This embodiment provides a method for manufacturing a rigid node 1 of a single-layer reticulated dome, the method comprising steps:

[0037] Assemble a lost pattern with the same shape and size as rigid node 1.

[0038] Manufacture a sand shell with a core matching the shape and size of the lost foam;

[0039] Rigid node 1 is formed by casting.

[0040] Therefore, the rigid node 1 of the single-layer reticulated shell with various angles is directly formed integrally by the lost foam casting, the structural integrity is better, there is no connection stress concentration point, and the mechanical properties of the rigid node 1 are better. At the same time, the work intensity of workers is reduced, the processing efficiency is improved, and the processing cost is reduced.

[0041] Step S101 , assembling an evaporative pattern with the same shape and size as the rigid node 1 .

[0042] To produce the rigid node 1 by casting, it is necessary to solve the problem of cooper...

Embodiment 2

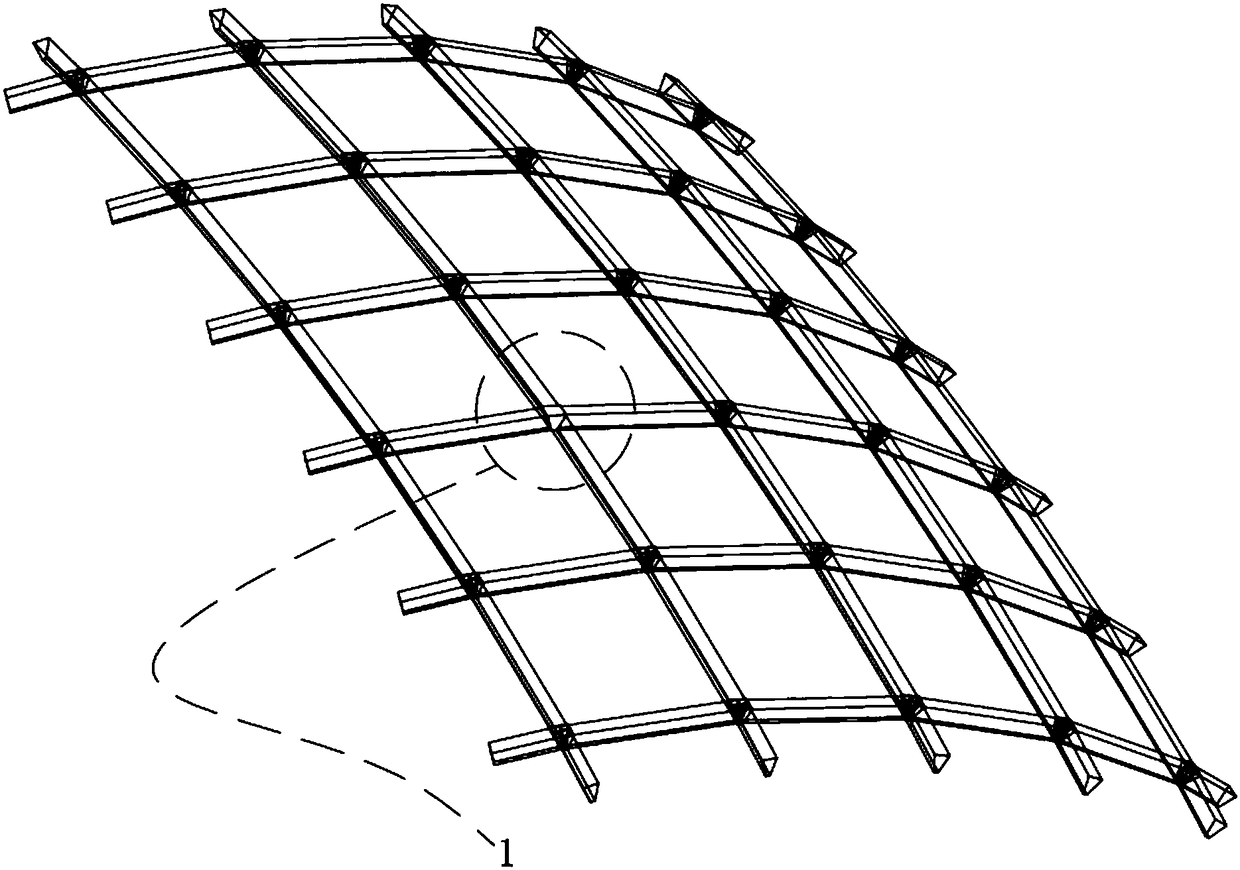

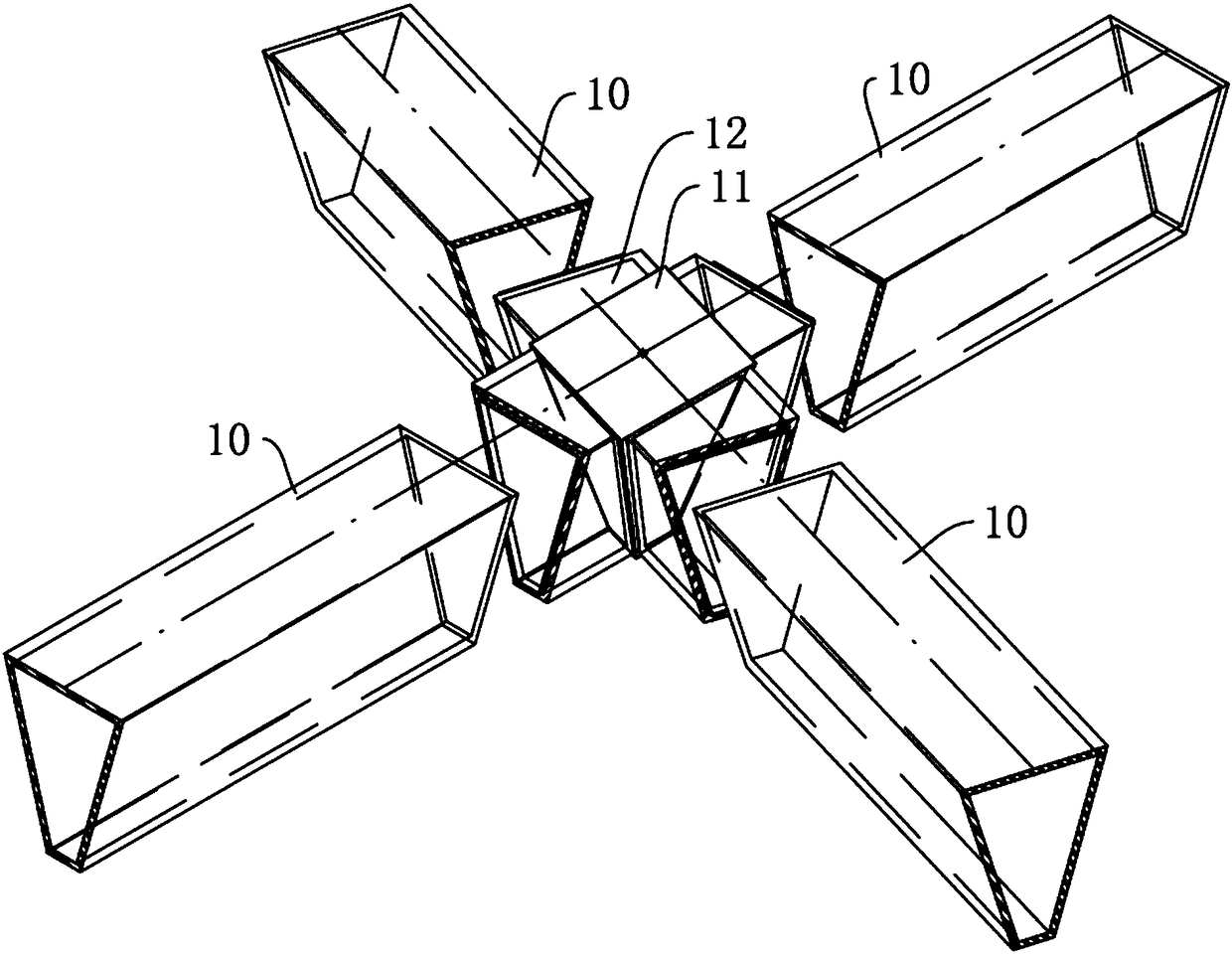

[0078] The present invention also provides a method for manufacturing a single-layer reticulated dome. The single-layer reticulated dome includes a rigid node 1 and a rod 10 . The rod 10 is connected to the rigid node 1 by connecting the connecting arm 12 of the rigid node 1 . The rigid node 1 is manufactured by the above-mentioned manufacturing method, and the rods 10 are connected to the rigid node 1 by welding to form a single-layer reticulated shell with a curved surface shape.

[0079] In this embodiment, the method for manufacturing a single-layer reticulated shell includes steps:

[0080] Make Rigid Node 1;

[0081] Spatial positioning of adjacent rigid nodes 1;

[0082] The rod 10 is welded on the rigid node 1.

[0083] In structural assembly, it is first necessary to spatially locate adjacent rigid nodes 1 of the single-layer shell structure and temporarily fix them, and then hoist the rods 10 between each rigid node 1 between adjacent rigid nodes 1 . The rod 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com