A self-pressurizing laundry ball

A laundry ball and automatic technology, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of wasting detergent, washing clothes with low degree of cleanliness, and failing to achieve the desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

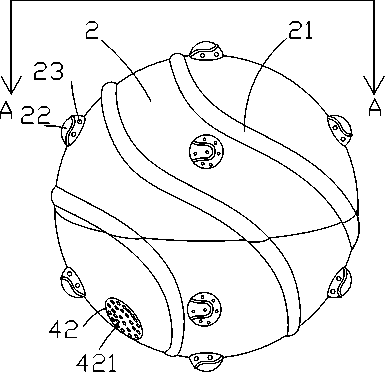

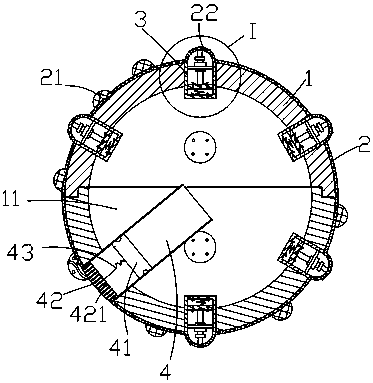

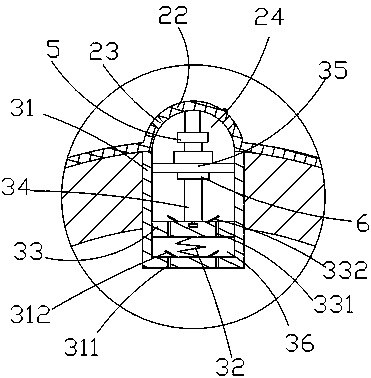

[0019] Figure 1 to Figure 4 It is a structural schematic diagram of the present invention.

[0020] The reference signs are: hollow sphere 1, storage bin 11, cleaning unit 2, kneading part 21, elastic convex body 22, liquid guide hole 23, liquid guide layer 24, pump head 3, cylinder 31, first discharge Hole 311, first one-way discharge structure 312, spring 32, second piston 33, second discharge hole 331, second one-way discharge structure 332, piston rod 34, guide sleeve 35, outlet hole 351, liquid storage Groove 36, feed pipe 4, first piston 41, pipe cover 42, water inlet 421, traction line 43, nut 5, protruding ring body 6.

[0021] Figure 1 to Figure 4 It is a structural schematic diagram of the present invention.

[0022] As shown in the figure: an automatic pressurized laundry ball of the present invention includes a hollow sphere 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com