Method for improving collagen heat stability by utilizing hydroxyapatite

A technology of hydroxyapatite and thermal stability, which is applied in the field of tanning, can solve the problems of increased cost, difficult treatment of suspended solids in production safety wastewater, troublesome operation, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

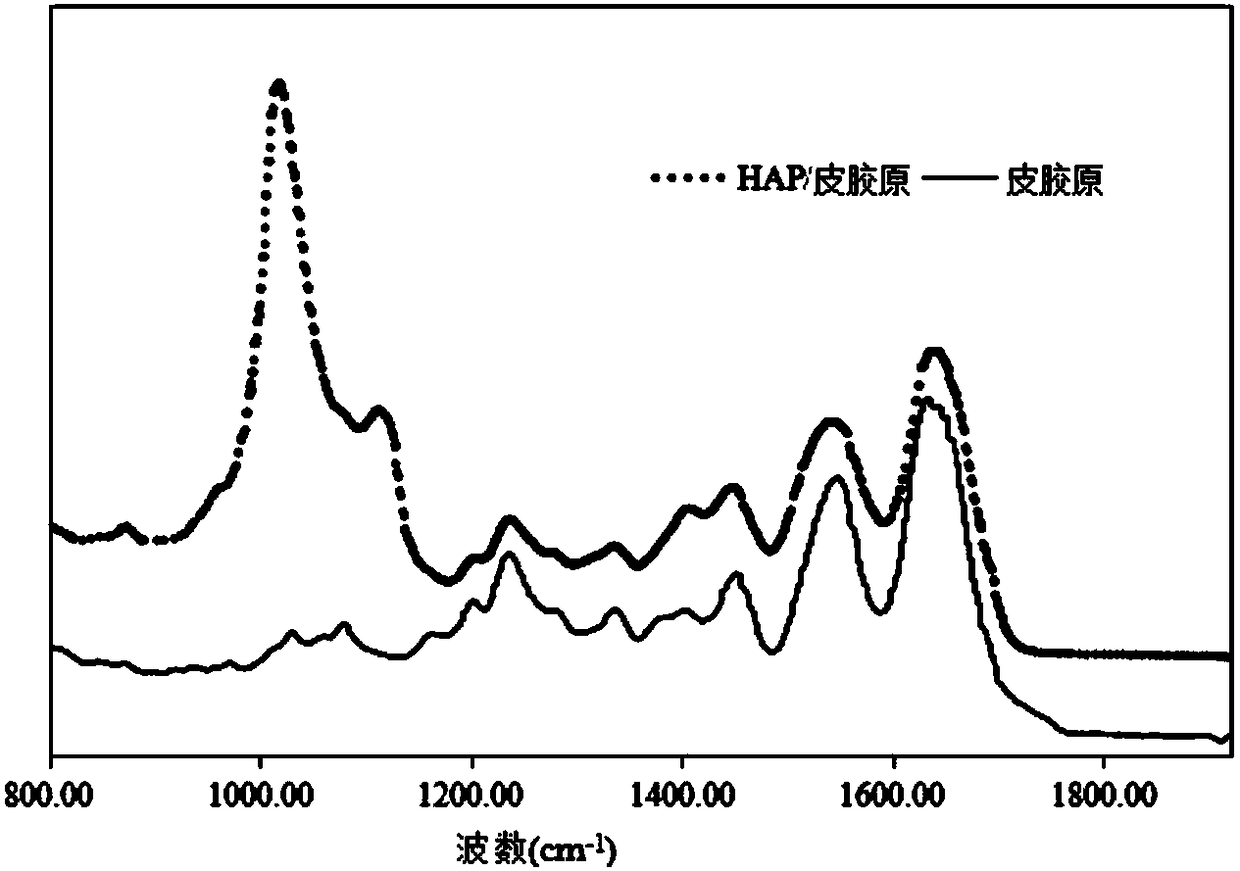

Image

Examples

Embodiment 1

[0015] Embodiment 1: Pickling under the higher temperature of softening cowhide

[0016] (1) In parts by weight, 2 parts of calcium chloride, 2.4 parts of sodium dihydrogen phosphate, and 10 parts of water are added to the container, heated to 85°C with steam, stirred, and kept at 85±5°C with a small amount of steam. After 2 hours, Keep it warm for 4-6 hours, cool down to 25-30°C, and set aside.

[0017] (2) After soaking in water, dehairing, liming, caustic soda skin, and weighing 100 parts of the gray skin are put into the drum, delimed, washed with water, and softened.

[0018] (3) Add the composition of (1) into the softening skin drum, then add 50 parts of 25°C water, rotate for 40-60 minutes, let stand for 60 minutes, rotate for 10 minutes, and drain.

[0019] (4) Pickling: add 50 parts of water, add 8-10 parts of common salt, rotate for 10 minutes, add acid (according to the requirements of pickling), and rotate (no need to add ice when the internal temperature is ≤35°...

Embodiment 2

[0020] Example 2: degreasing of softened sheepskin at a higher temperature

[0021] (1) According to parts by weight, 1.8 parts of calcium chloride, 2.2 parts of sodium hydrogen phosphate, and 10 parts of water are added to the container, heated to 85°C with steam, stirred, and kept at 85±5°C with a small amount of steam. After 2 hours, keep warm Let stand for 4-6 hours, cool down to 25-30°C, and set aside.

[0022] (2) After immersion, depilation, liming, and weighing 100 parts of gray skins, put them into the drum, deash, wash, and soften.

[0023] (3) Add the composition of (1) into the softening skin drum, then add 50 parts of 25°C water, rotate for 40-60 minutes, let stand for 60 minutes, rotate for 10 minutes, and drain.

[0024] (4) Degreasing: Add 50 parts of water at 40°C to the drum, add 2.0 to 3 parts of degreasing agent, rotate for 40 minutes, drain, add 100 parts of water at 40±2°C, rotate for 20 minutes, and drain. Enter normal pickling.

Embodiment 3

[0025] Embodiment 3: degreasing under the higher temperature of softening pigskin

[0026] (1) According to the parts by weight, 2.4 parts of calcium nitrate, 2.4 parts of sodium dihydrogen phosphate, and 10 parts of water are added to the container, heated to 85°C with steam, stirred, and kept at 85±5°C with a small amount of steam. After 2 hours, keep warm Let stand for 4-6 hours, cool down to 25-30°C, and set aside.

[0027] (1) According to the parts by weight, 2) After soaking in water, dehairing, liming, and weighing 100 parts of gray skins, put them into a drum, deliming, washing, and softening.

[0028] (3) Add the composition of (1) into the softening skin drum, then add 50 parts of 25°C water, rotate for 40-60 minutes, let stand for 60 minutes, rotate for 10 minutes, and drain.

[0029] (4) Degreasing: Add 50 parts of water at 40±2°C to the drum, add 1.5 to 2 parts of degreasing agent, rotate for 40 minutes, drain, add 100 parts of water at 40°C, rotate for 20 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com