Application of aminated mesoporous silica nanomaterial as lubricating oil antiwear agent

A technology of mesoporous silica and nanomaterials, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of exhaust gas pollution, corrosion of friction pair materials, etc., and achieve simple preparation method, high-efficiency lubrication, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

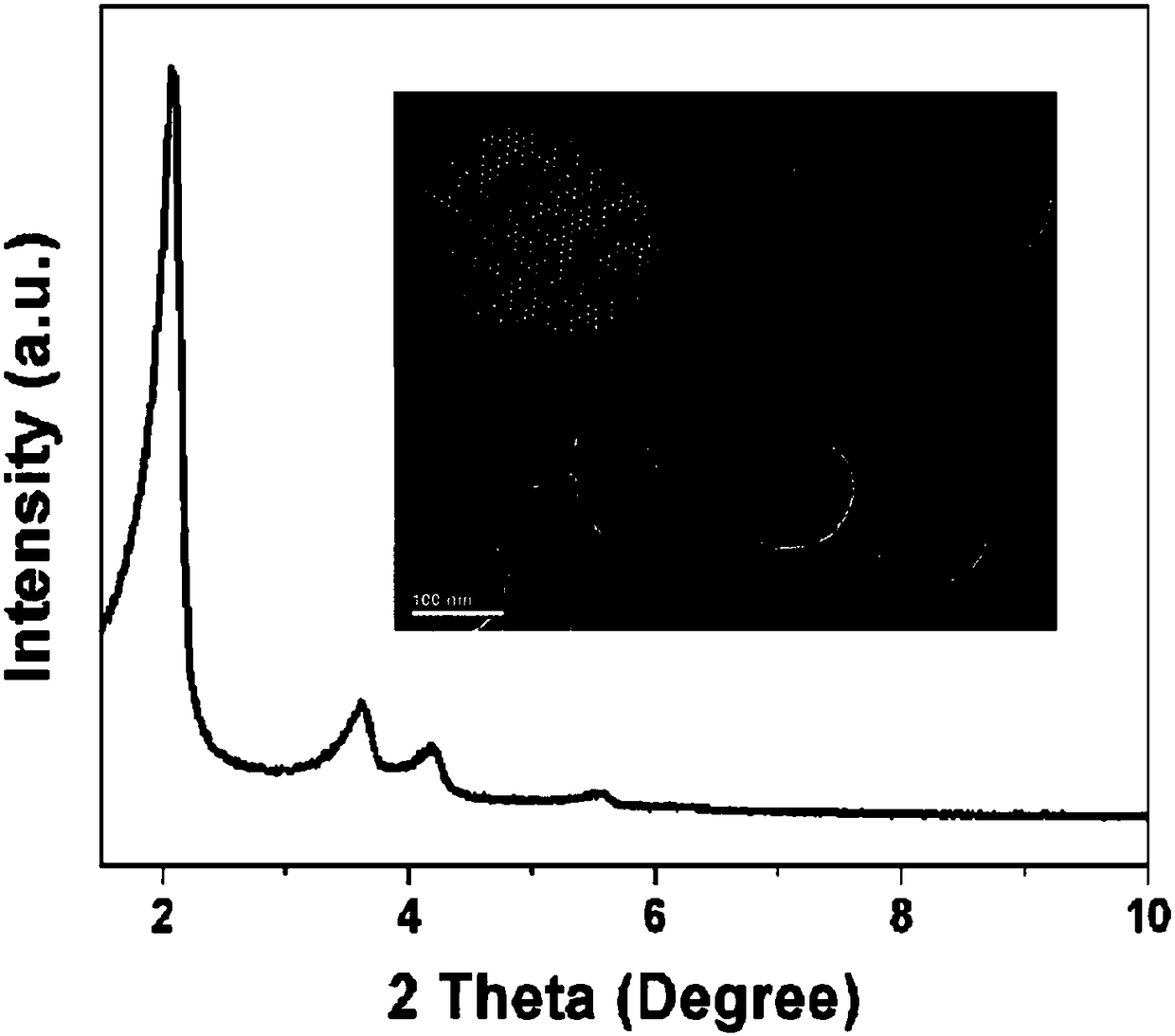

Image

Examples

Embodiment 1

[0040] The aminated mesoporous silicon dioxide nanometer material is applied as a lubricating oil antiwear agent, and the aminated mesoporous silicon dioxide nanometer material is prepared by modification with KH550.

[0041] The preparation method of the described aminated mesoporous silica nanomaterial comprises the following steps:

[0042](1) Dissolve CTAB in deionized water, then add EG and NH 3 ·H 2 O aqueous solution, and fully dissolved;

[0043] (2) Add TEOS dropwise, then add KH550;

[0044] At this time, KH550, CTAB, TEOS, NH in the mixed system 3 ·H 2 The mass ratio of O, EG and deionized water is 1:6:8:42:230:1100;

[0045] (3) Continue stirring the mixed system obtained in step (2) at 55°C for 1 hour, then transfer it into a reaction kettle, and conduct hydrothermal synthesis at 110°C for 20 hours;

[0046] (4) Centrifuge at 15000rpm for 10min, wash with absolute ethanol and deionized water, and then vacuum dry at 55°C for 10h;

[0047] (5) HCl and ethanol...

Embodiment 2

[0053] The aminated mesoporous silica nanomaterial is applied as a lubricating oil antiwear agent, and the aminated mesoporous silica nanomaterial is prepared after modification with KH550, and the aminated mesoporous silica The particle size of silicon nanomaterials is 80-100nm.

[0054] The preparation method of the described aminated mesoporous silica nanomaterial comprises the following steps:

[0055] (1) Dissolve CTAB in deionized water, then add EG and NH 3 ·H 2 O aqueous solution, and fully dissolved;

[0056] (2) Add TEOS dropwise, then add KH550;

[0057] At this time, KH550, CTAB, TEOS, NH in the mixed system 3 ·H 2 The mass ratio of O, EG and deionized water is 1:7:6.5:55:200:1150;

[0058] (3) Continue stirring the mixed system obtained in step (2) at 45°C for 2.5h, then transfer it into a reaction kettle, and conduct hydrothermal synthesis at 90°C for 30h;

[0059] (4) Centrifuge at 10000rpm for 20min, wash with absolute ethanol and deionized water, and th...

Embodiment 3

[0066] The aminated mesoporous silica nanomaterial is applied as a lubricating oil antiwear agent, and the aminated mesoporous silica nanomaterial is prepared after modification with KH550, and the aminated mesoporous silica The particle size of silicon nanomaterials is 80-100nm.

[0067] The preparation method of the described aminated mesoporous silica nanomaterial comprises the following steps:

[0068] (1) Dissolve CTAB in deionized water, then add EG and NH 3 ·H 2 O aqueous solution, and fully dissolved;

[0069] (2) Add TEOS dropwise, then add KH550;

[0070] At this time, KH550, CTAB, TEOS, NH in the mixed system 3 ·H 2 The mass ratio of O, EG and deionized water is 1:6.5:7:50:210:1133;

[0071] (3) Continue stirring the mixed system obtained in step (2) at 50°C for 2h, then transfer it into a reaction kettle, and conduct hydrothermal synthesis at 100°C for 24h;

[0072] (4) Centrifuge at 12000rpm for 15min, wash with absolute ethanol and deionized water, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com