Transverse caulking and stacking device for paperboards

A laminating and horizontal technology, which is applied in stack receiving devices, transportation and packaging, thin material handling, etc., can solve the problems of poor laminating effect, impact of stacking height, high labor intensity, etc., and achieve good laminating effect , increase the number of palletizing, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

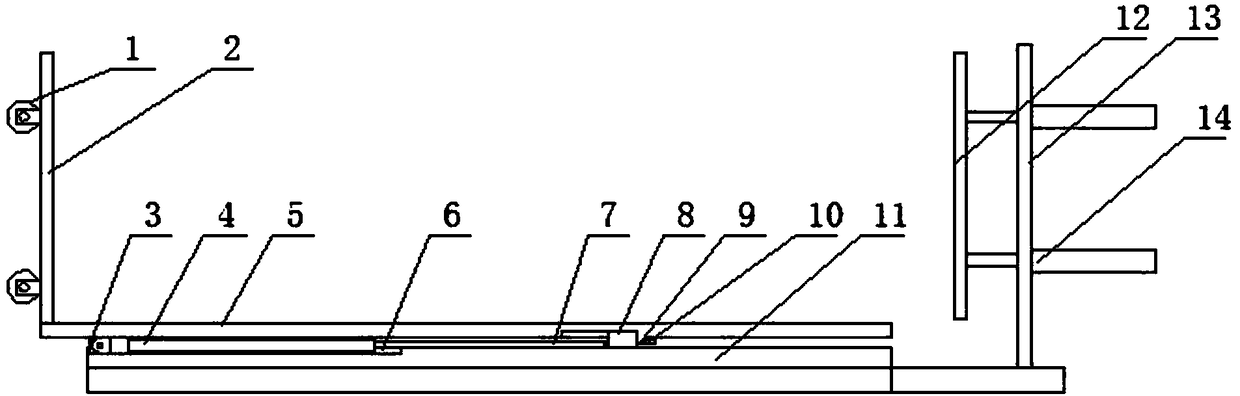

[0017] A cardboard horizontal lamination stacking device, which includes a fixed seat 11, a mobile frame and a laminating mechanism, the mobile frame includes a horizontal frame body 5 and a vertical frame 2 fixed on one side of the horizontal frame body, and a cylinder drive is installed on the fixed seat. mechanism, the cylinder driving mechanism includes a cylinder 4, a left connecting rod and a right connecting rod, the cylinder body of the cylinder and the left connecting rod are rotated and installed, and the two ends of the left connecting rod slide on the guide rail 6 of the fixed seat through the sliding seat 3, and the cylinder The cylinder rod 7 and the right connecting rod are rotatably installed, and the right connecting rod two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com