Carding machine for hose

A hose and frame technology, which is applied in the field of carding and arranging machines for hoses, can solve problems such as low production efficiency, difficulty in neatly arranging, and easy entanglement of slender hoses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

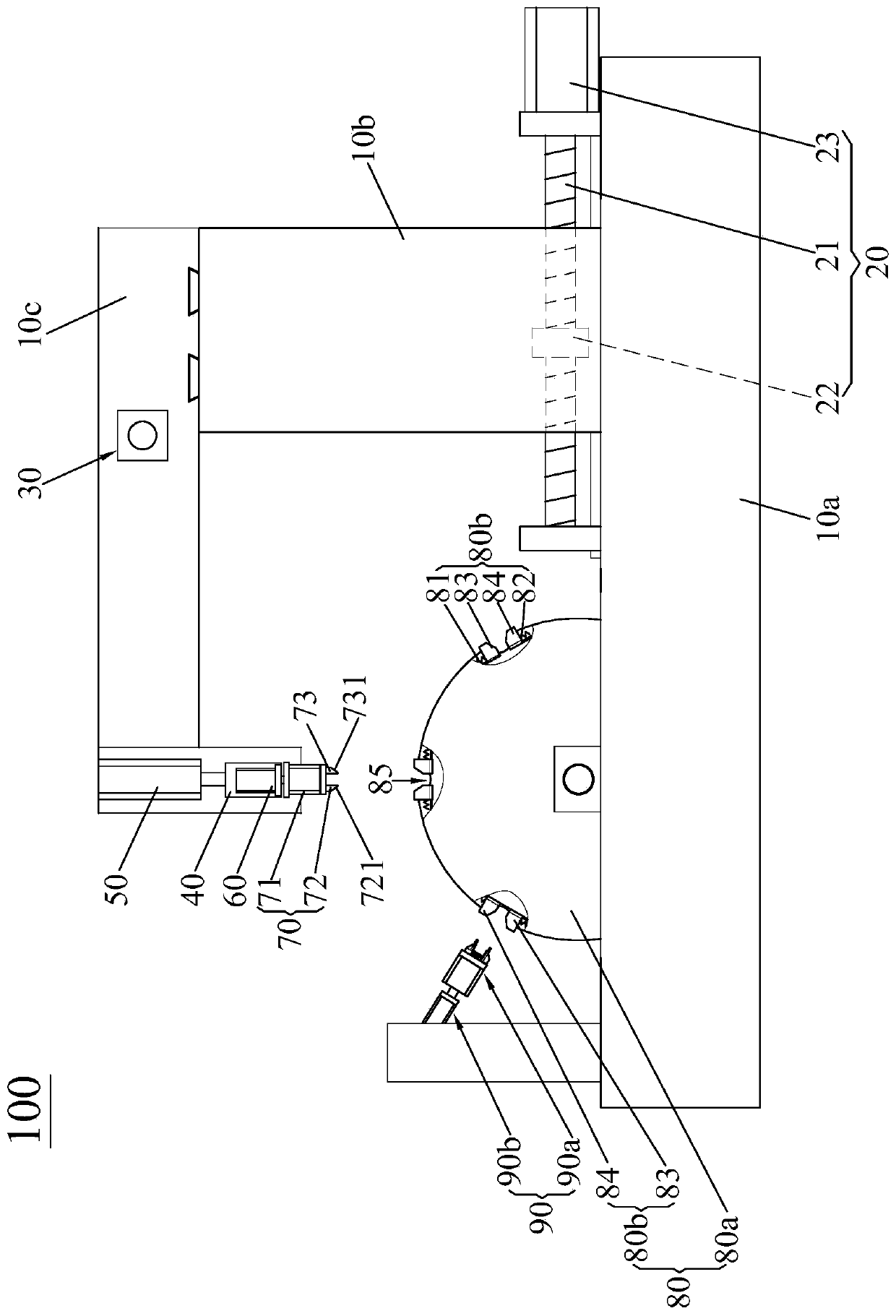

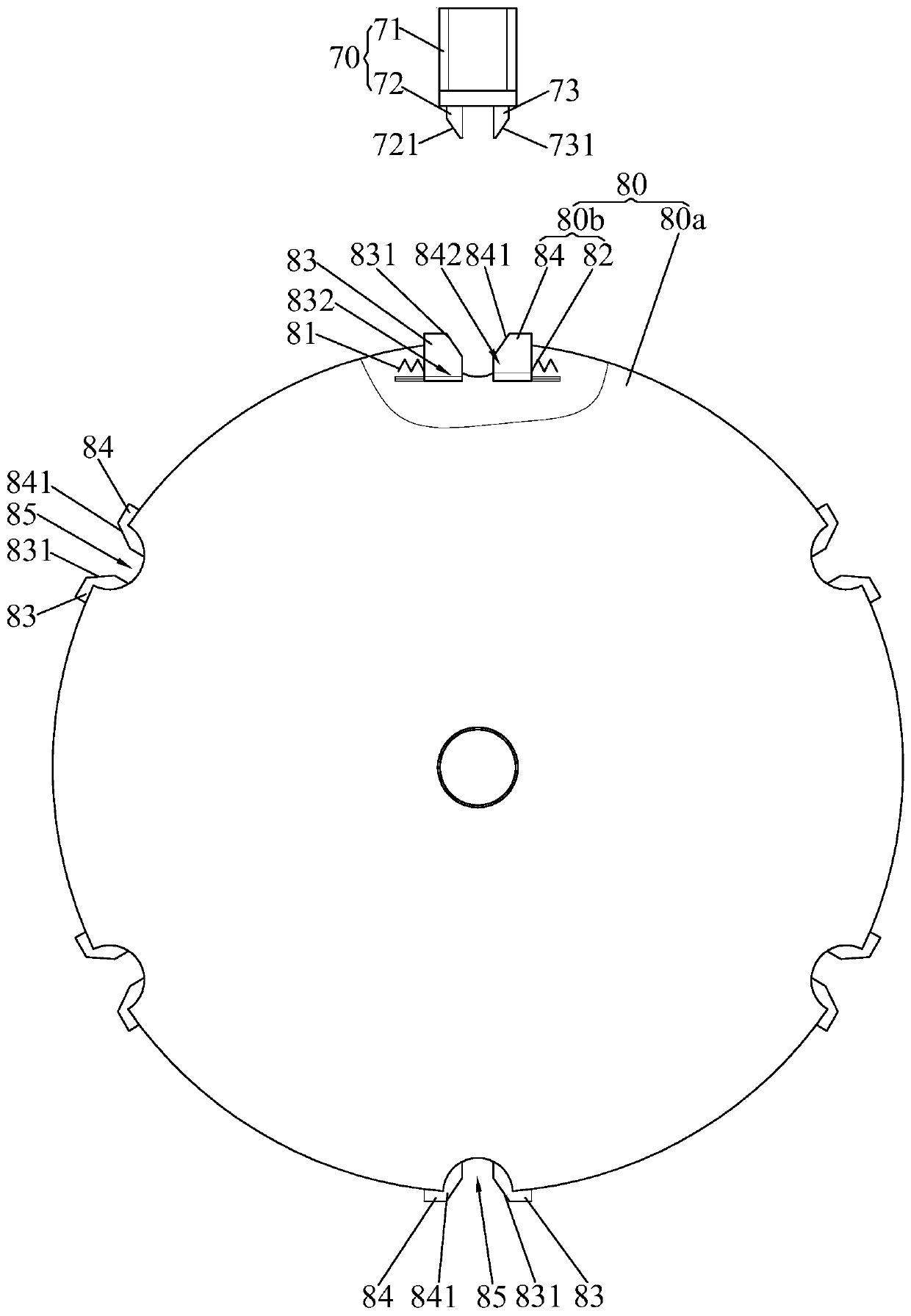

[0021] see Figure 1 to Figure 3 , the hose of the present invention is used for the hose 200 (see Figure 4a ) for automatic combing to reduce the burden on operators.

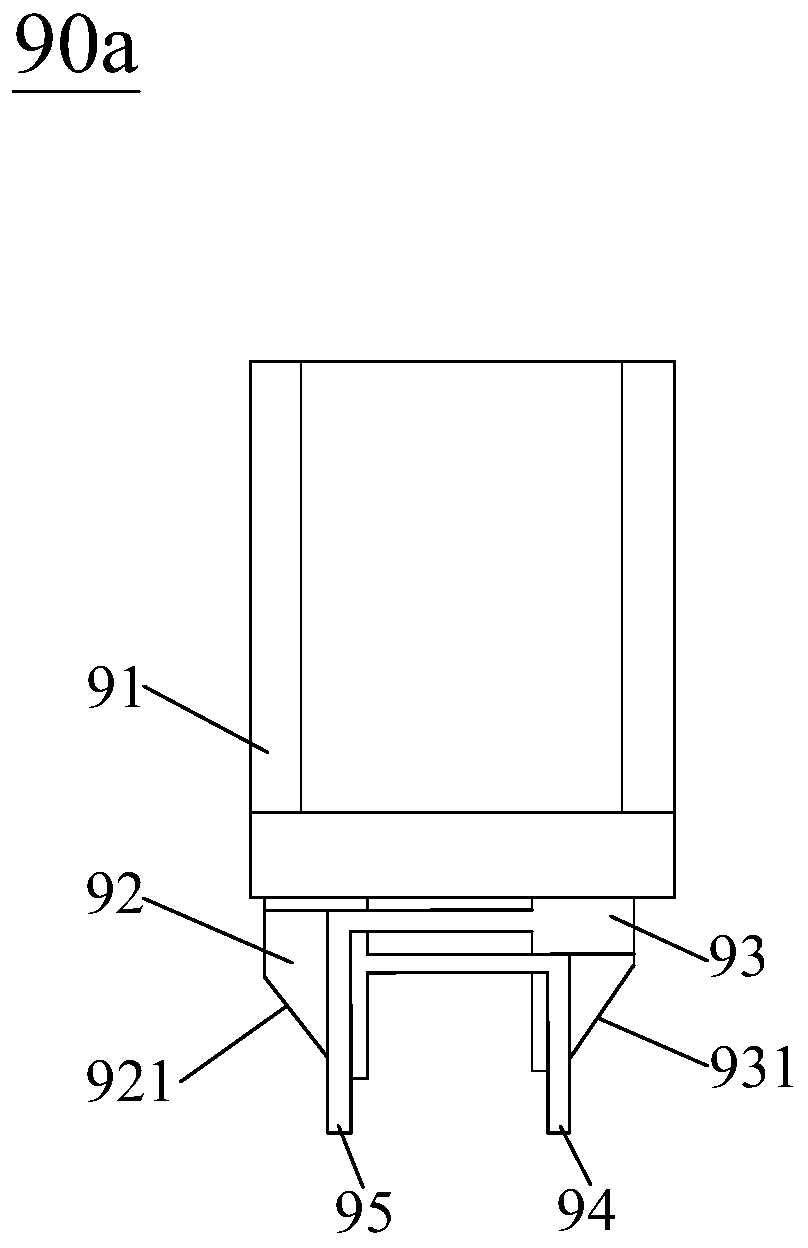

[0022] Wherein, the hose carding and arranging machine 100 of the present invention includes a frame 10a, a left and right carriage 10b, a left and right driving mechanism 20, a front and rear carriage 10c, a front and rear driving mechanism 30, a lifting seat 40, a lifting cylinder 50, a rotating motor 60, a pneumatic Finger 70 and sorting mechanism 80. The left and right slide frames 10b are slidably arranged on the frame 10a along the left and right directions of the frame 10a, so that the left and right slide frames 10b can slide in the left and right directions relative to the frame 10a; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com