Forming method of steamed pork dumplings

A molding method and siu mai technology, which is applied in baking, dough processing, food science, etc., can solve the problems of affecting the appearance of the product, destroying the shape of siu mai, and low efficiency, so as to achieve good molding quality, avoid punctures, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for forming siu mai, comprising the steps of:

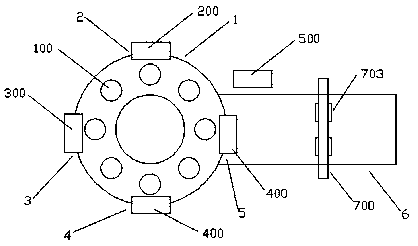

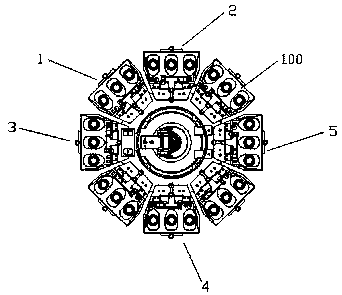

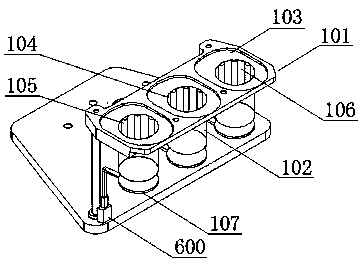

[0038] In the first step, the forming mold 100 is located at the skinning station 2 of the station turntable 1, and the dough conveying device 200 drops the dough on the skinning plate 101 of the forming mold 100 at the skinning station 2;

[0039] In the second step, the forming mold 100 moves with the station turntable 1 to the filling station 3, and the filling device 300 injects the filling on the dough and simultaneously pushes the dough downwards, so that the dough is in the shape of a pocket;

[0040] In the third step, the forming mold 100 continues to move to the forming station 4, and the peeling device 400 pushes the dough into the mold cup 102 below the skin connecting plate 101 for molding;

[0041] In the fourth step, the forming mold 100 moves to the output station 5, and the piercing device 400 located at the output station 5 pokes the siu mai out of the mold cup 102 from top to bottom, and at the ...

Embodiment 2

[0045] A method for forming siu mai, comprising the steps of:

[0046] In the first step, the forming mold 100 is located at the skinning station 2 of the station turntable 1, and the dough conveying device 200 drops the dough on the skinning plate 101 of the forming mold 100 at the skinning station 2;

[0047] In the second step, the forming mold 100 moves with the station turntable 1 to the filling station 3, and the filling device 300 injects the filling on the dough and simultaneously pushes the dough downwards, so that the dough is in the shape of a pocket;

[0048] In the third step, the forming mold 100 continues to move to the forming station 4, and the peeling device 400 pushes the dough into the mold cup 102 below the skin connecting plate 101 for molding;

[0049] In the fourth step, the forming mold 100 moves to the output station 5, and the piercing device 400 located at the output station 5 pokes the siu mai out of the mold cup 102 from top to bottom, and at the ...

Embodiment 3

[0054] A method for forming siu mai, comprising the steps of:

[0055] In the first step, the forming mold 100 is located at the skinning station 2 of the station turntable 1, and the dough conveying device 200 drops the dough on the skinning plate 101 of the forming mold 100 at the skinning station 2;

[0056] In the second step, the forming mold 100 moves with the station turntable 1 to the filling station 3, and the filling device 300 injects the filling on the dough and simultaneously pushes the dough downwards, so that the dough is in the shape of a pocket;

[0057] In the third step, the forming mold 100 continues to move to the forming station 4, and the peeling device 400 pushes the dough into the mold cup 102 below the skin connecting plate 101 for molding;

[0058] In the fourth step, the forming mold 100 moves to the output station 5, and the piercing device 400 located at the output station 5 pokes the siu mai out of the mold cup 102 from top to bottom, and at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com