A three-stage culture method of turbot in circulating water

A technology of turbot and circulating water, applied in fish farming, application, climate change adaptation, etc., can solve problems such as high energy consumption, uneven breeding management level, waste of resources, etc., to improve breeding production efficiency and ensure The effect of breeding production safety and reducing the risk of disease occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The three-stage culture method of turbot circulating water, the specific operation is as follows:

[0015] Each set of recirculating aquaculture system in the turbot breeding workshop of Oriental Ocean Laizhou Branch is composed of a water treatment unit consisting of a microfiltration machine, protein foam separator, ultraviolet lamp, ozone, oxygen cone, and biological filter, and 10 breeding ponds. The effective area of the pond is 30 square meters. Each pond is adjusted to a water depth of 50cm, and the effective breeding water body is about 15m 3 .

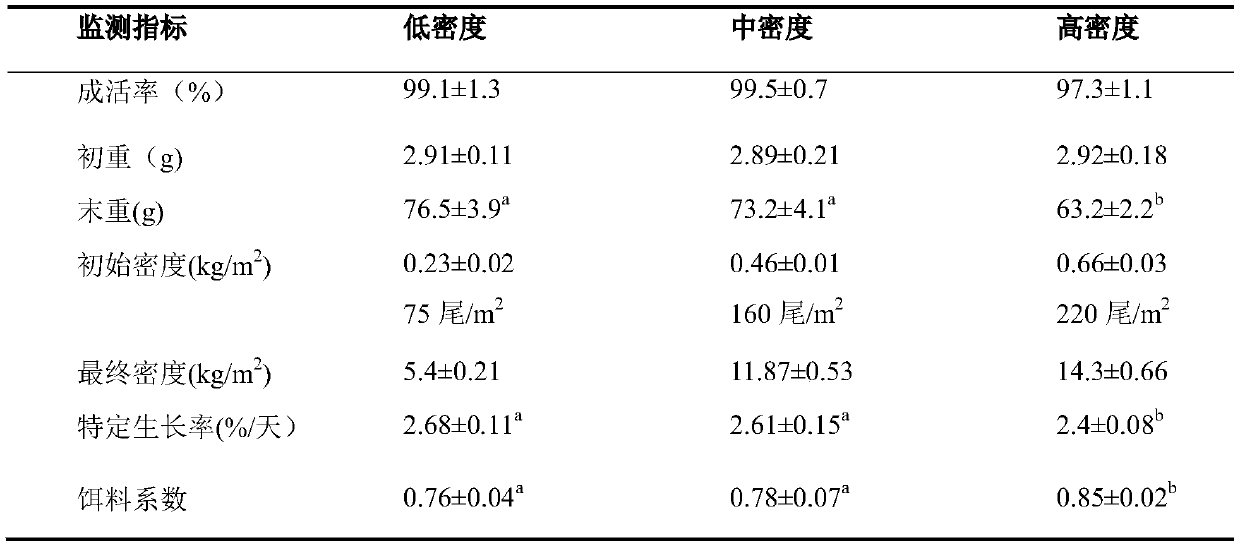

[0016] In the first stage, a total of 41,000 turbot fry with an initial average weight of 2.9 g and a body length of about 5 cm were stocked in a culture system at high, medium, and low densities, of which 6,750 were stocked at three low densities. Breeding ponds, the breeding density is 75 fish / ㎡, 14400 fish are stocked in three breeding ponds at medium density, the breeding density is 160 fish / ㎡, 19800 fish are sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com