Subsoiler with plowing depth compensation mechanism

A compensation mechanism and subsoiler technology, which is applied in agricultural machinery and implements, soil preparation machinery, agriculture, etc., can solve the problem that subsoil ploughing depth is difficult to reach the predetermined ploughing depth, cannot completely break the bottom of the plough, and cannot achieve the expected subsoiling effect. and other problems, to achieve the effect of maintaining ploughing depth, improving the quality of subsoil operations, and reducing traction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described below in conjunction with accompanying drawing.

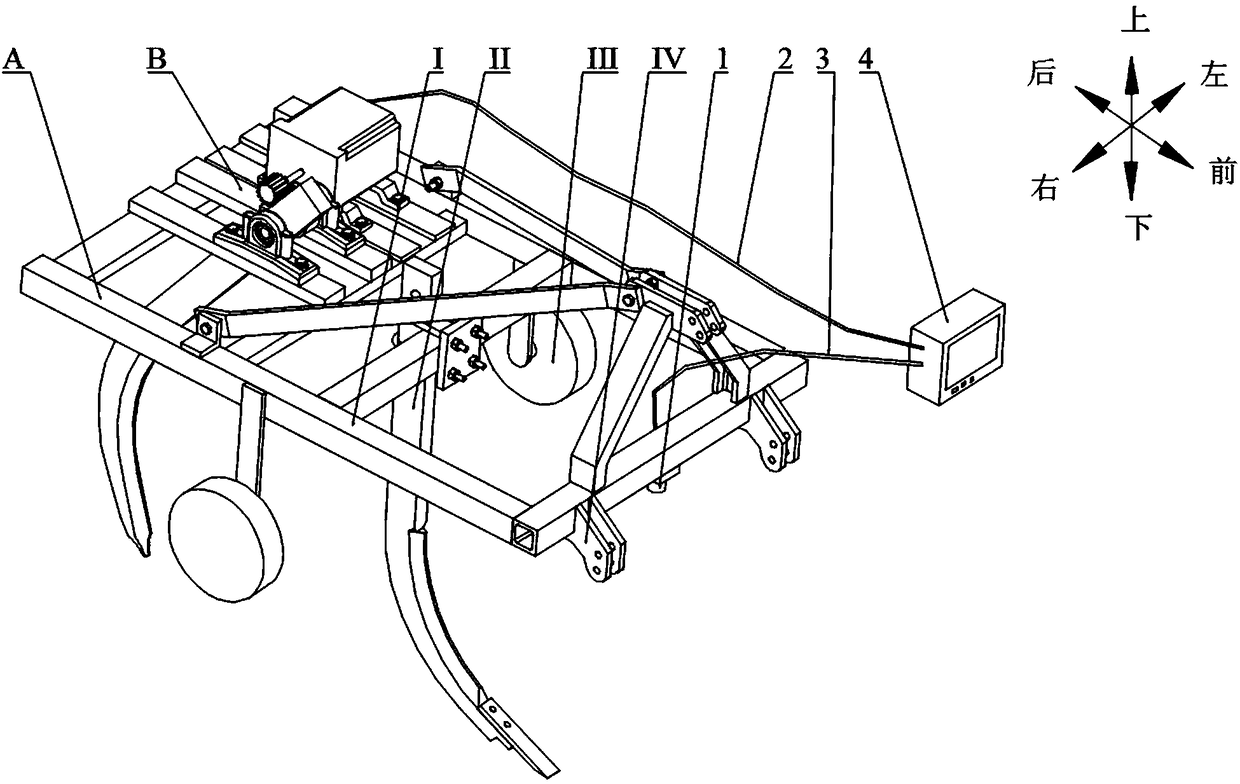

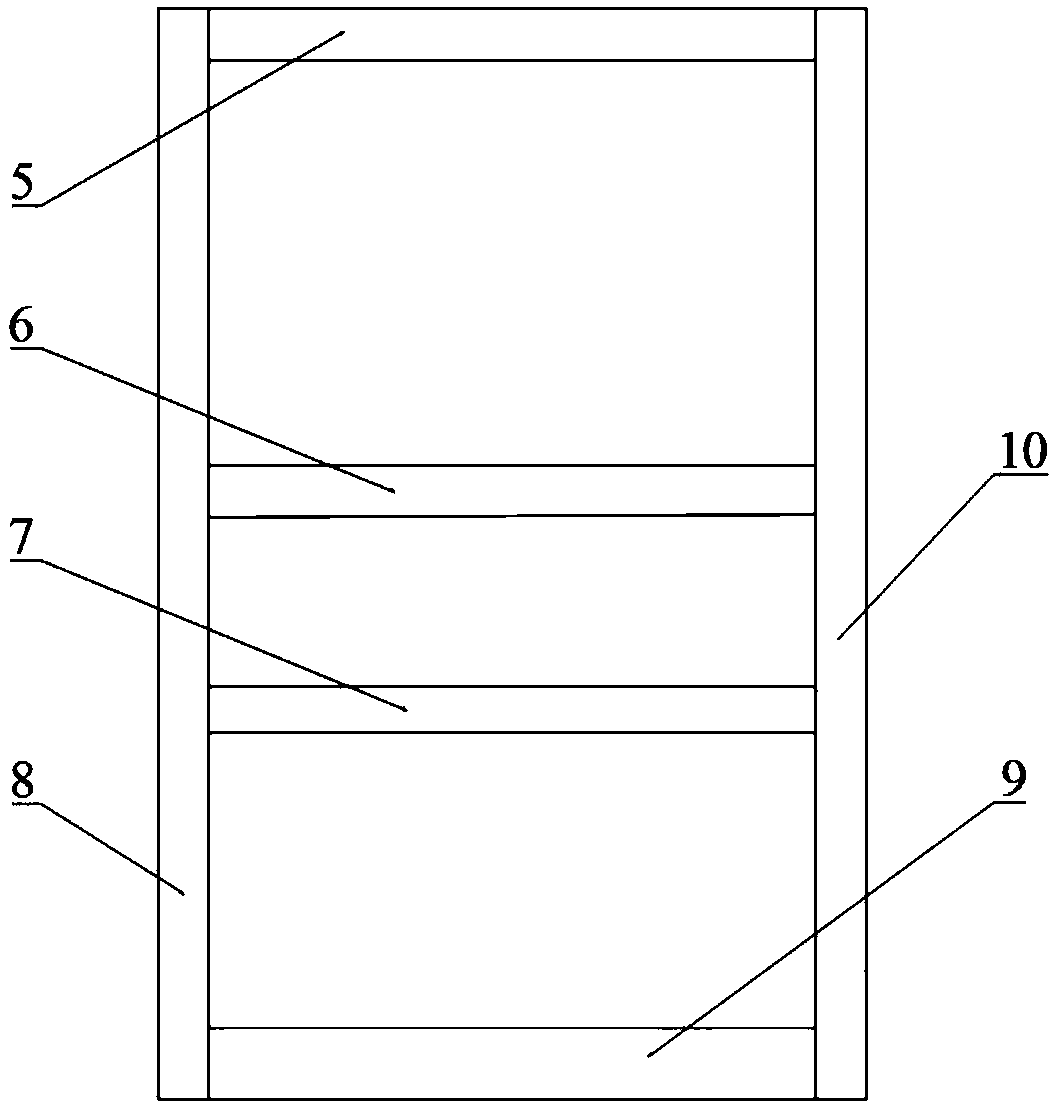

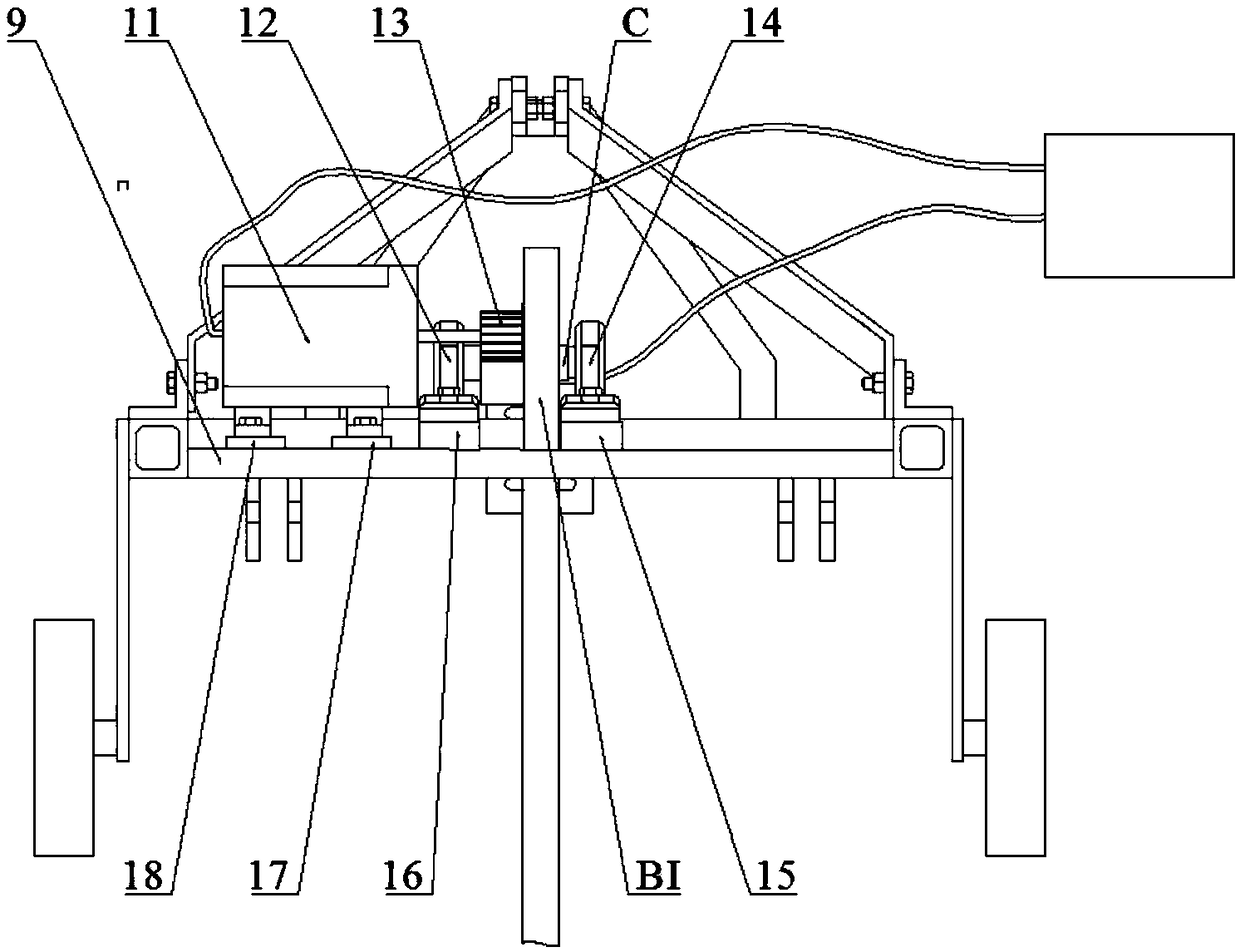

[0021] Such as figure 1 As shown, the present invention is composed of original subsoiler A, tillage depth compensation mechanism B, tillage depth sensor 1, wire I2, wire II3 and microcomputer 4; the original subsoiler A is composed of frame I, subsoiler Ⅱ. Depth limiting device Ⅲ and suspension device Ⅳ, in which frame Ⅰ is composed of front crossbeam 5, middle crossbeam Ⅰ6, middle crossbeam Ⅱ7, left longitudinal beam 8, rear crossbeam 9 and right longitudinal beam 10. figure 2 As shown, the front crossbeam 5, middle crossbeam I6, middle crossbeam II7 and rear crossbeam 9 are arranged in parallel in sequence, and the two ends of the front crossbeam 5, middle crossbeam I6, middle crossbeam II7 and rear crossbeam 9 are fixed to the left longitudinal beam 8 and the right longitudinal beam respectively. The inner side of the beam 10 is in the shape of "mesh"; the subsoiling device II is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com