Angle displacement sensor automatic calibration system and method

An angular displacement sensor and displacement sensor technology, applied in the field of sensor calibration, can solve the problems of traceability, low efficiency, error-prone versatility, etc., and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

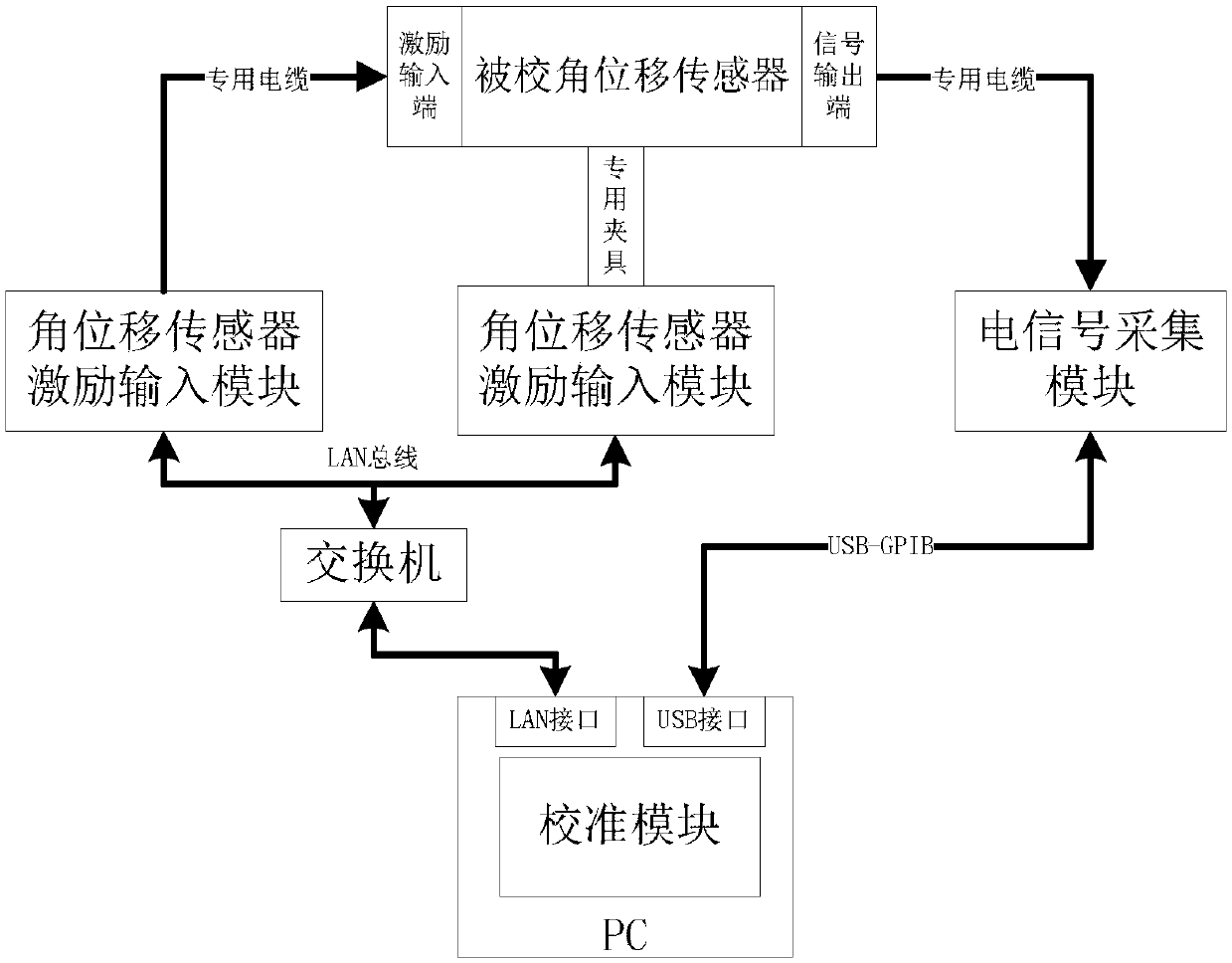

[0044] from figure 1 It can be seen that this embodiment includes an angular displacement control module, two angular displacement sensor excitation input modules, an electrical signal acquisition module and a calibration module; wherein the output end of the angular displacement sensor excitation input module is connected to the excitation input end of the angular displacement sensor to be calibrated connection; the excitation output end of the angular displacement sensor to be calibrated is connected to the input end of the electrical signal acquisition module; the angular displacement control module, the excitation input module of the angular displacement sensor and the electrical signal acquisition module are all connected to the calibration module.

[0045] The angular displacement control module is used to fix the angular displacement sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com