A method of passing through the high rise area along the trench in fully mechanized mining face

A technology for fully mechanized mining face and high-risk area, which is applied in ground mining, mining equipment, underground mining, etc. It can solve problems such as unsafe construction and affecting mine mining, and achieve the effect of preventing the end support from toppling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

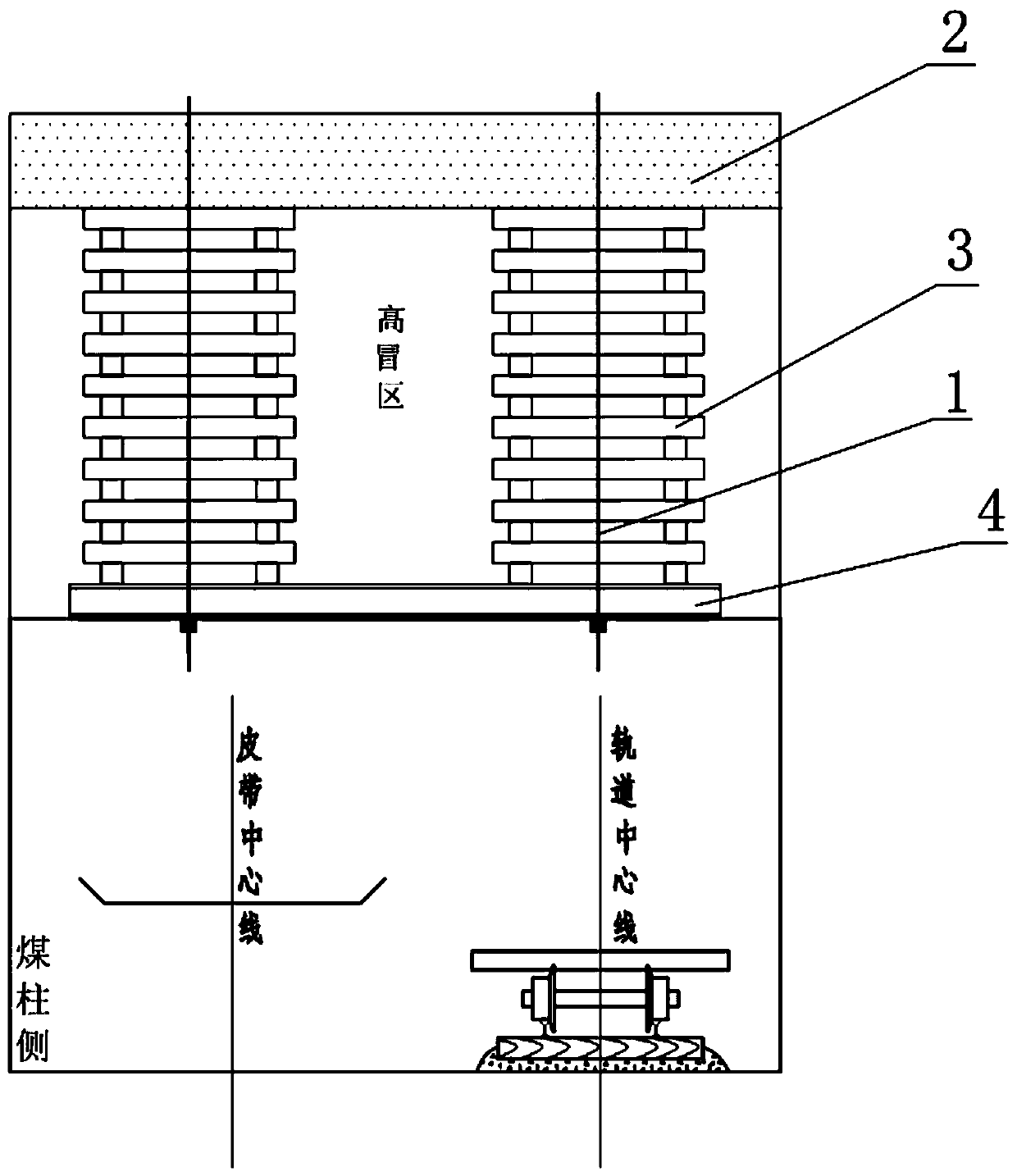

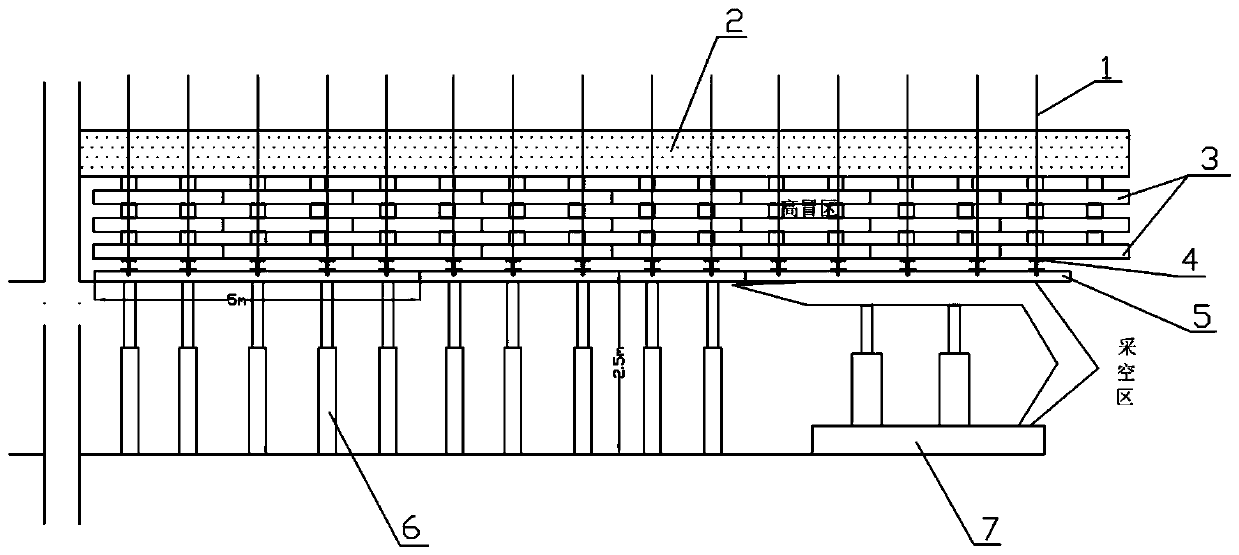

[0022] A method for passing a high-risk area of a fully mechanized mining face along a trough, comprising the following steps:

[0023] a. Set up artificial false roofs in the high-risk area in advance. During construction, according to the section width of the roadway and the length of the high-risk area, two rows of anchor cables are arranged in the high-risk area according to the center line of the roadway; The height of the back alley is 2.5 meters, and the top of the shed beam is braked with square wood in a "well" shape, and the length of the shed beam is consistent with the width of the roadway;

[0024] b. After the brake roof is supported, the coal wall at a distance of 3m before and after the high risk area and the coal wall below the high risk area are drilled and injected every 5m along the roadway. The injection is stopped until the amount of powder is overflowed from the coal wall;

[0025] c. Advance support, 20m away from the high-risk area in the headway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com