Piston regulated hydraulic impactor

A technology of hydraulic impactor and piston, which is applied to the driving device for drilling in the borehole, earthwork drilling and production, drilling equipment, etc. It can solve the problem of poor impact effect of the hydraulic impactor and achieve the effect of increasing the drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

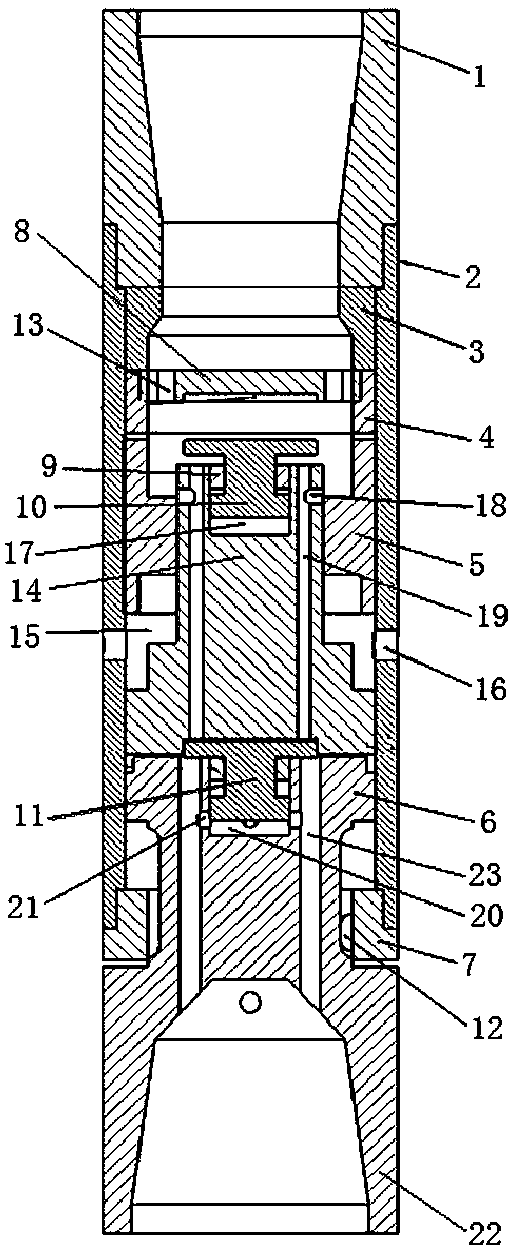

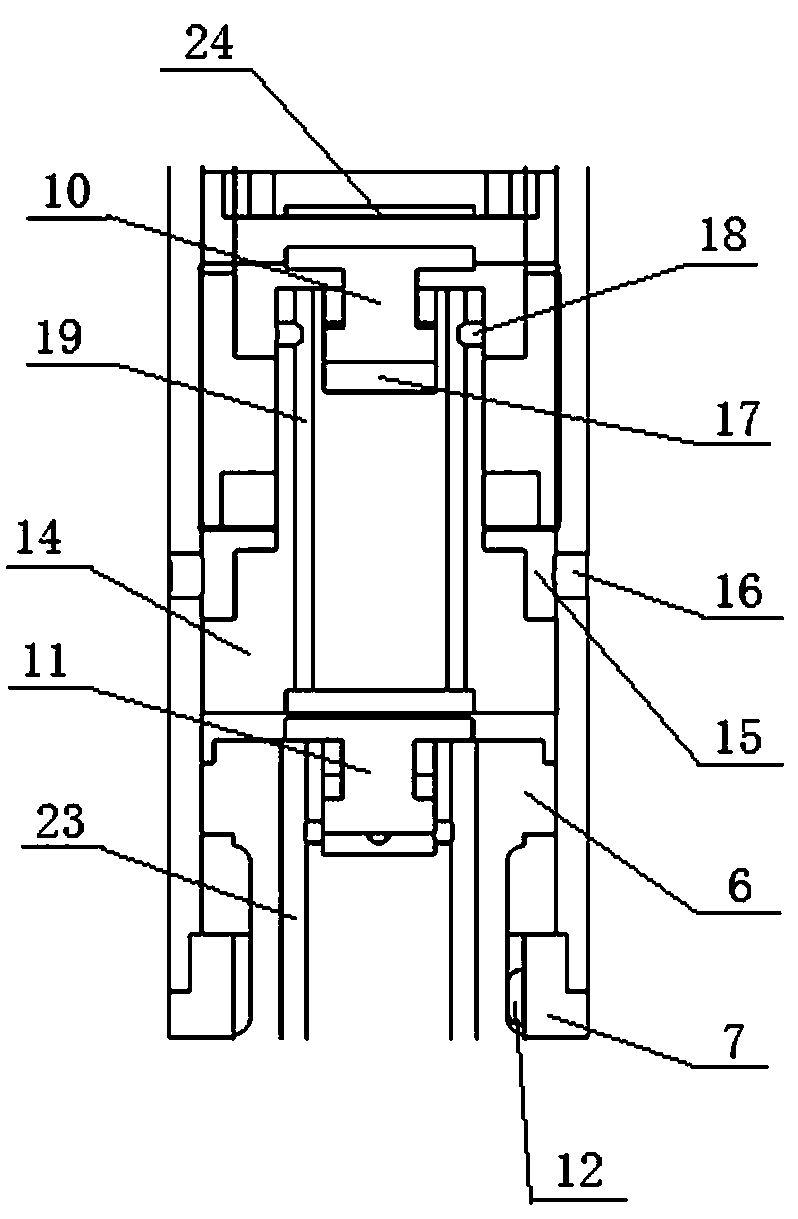

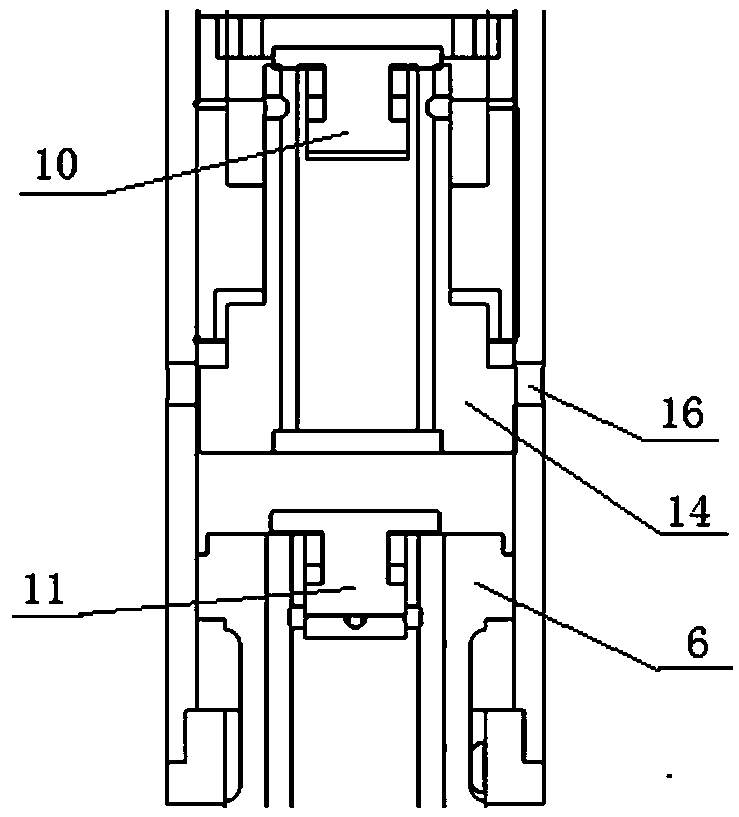

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

[0020] Such as figure 1 As shown, the piston-controlled hydraulic impactor includes an upper conversion joint 1, an upper spacer sleeve 3, a housing 2, a valve cover 8, an impact hammer 14, an anvil 6, and a limit nut 7. The upper conversion joint 1 passes through The thread is connected with the drill collar, and the lower adapter 22 is connected with the drill bit through the thread; the shell 2 is a cylinder, the upper end of the shell 2 is threaded with the upper adapter 1, the anvil 6 is set at the lower end of the shell 2, and the limit nut 7 is set Between housing 2 and anvil 6, stop nut 7 and anvil 6 are provided with drive pin 12, and the lower end of anvil 6 is lower conversion joint 22, and stop nut 7 is used for limiting the movement of anvil 6; 5 is fastened in the housing 2, the upper spacer sleeve 3 and the valve seat 4 are arranged between the upper conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com