Novel building mortar finishing machine

A plastering machine and construction technology, applied in the direction of construction, building structure, etc., can solve problems such as affecting construction quality, mortar cracks, depressions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

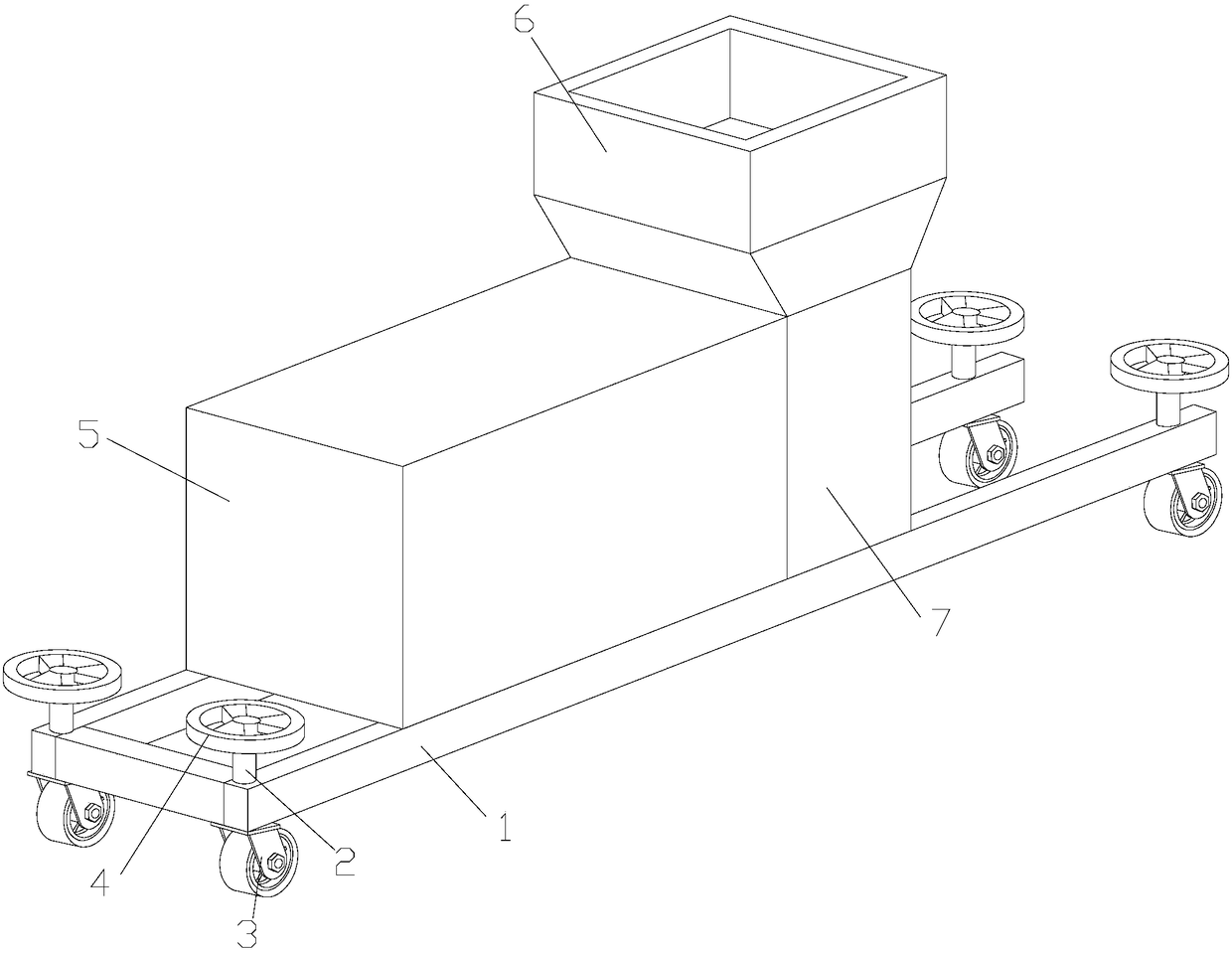

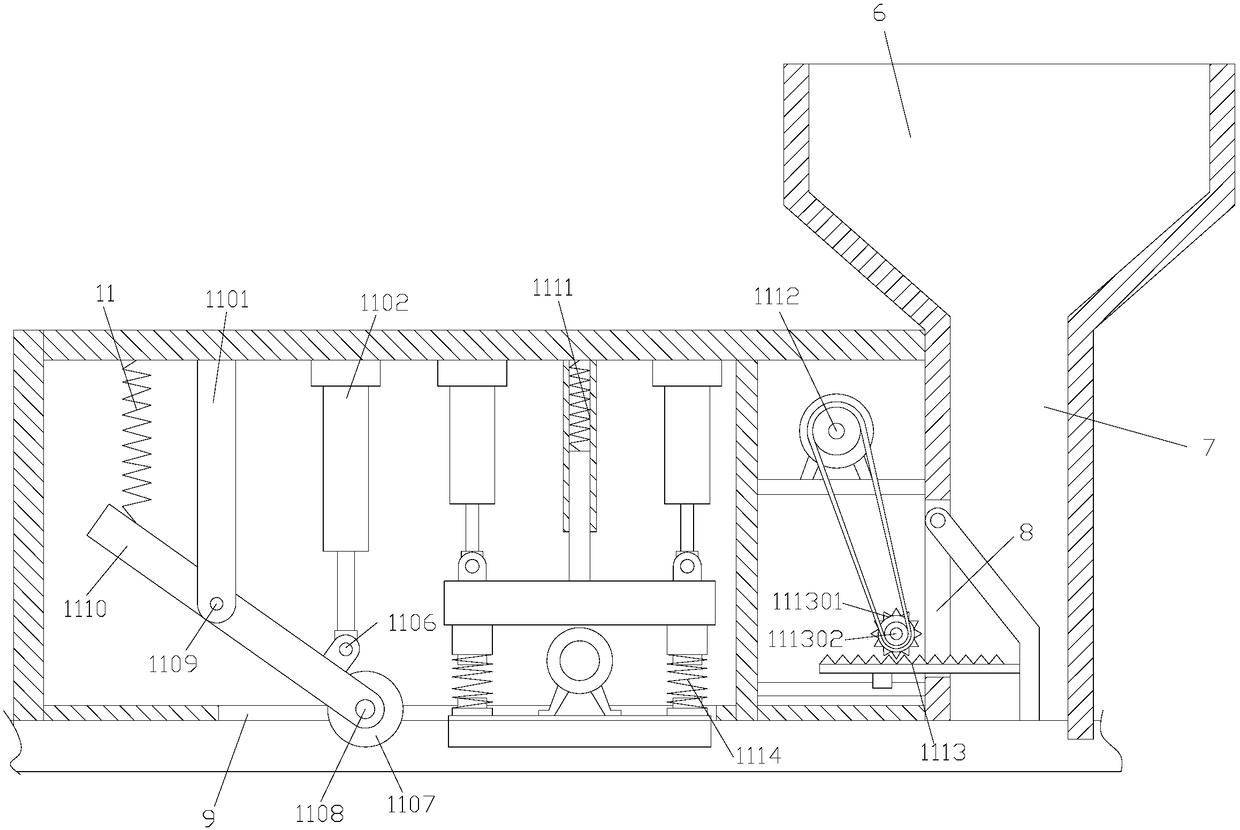

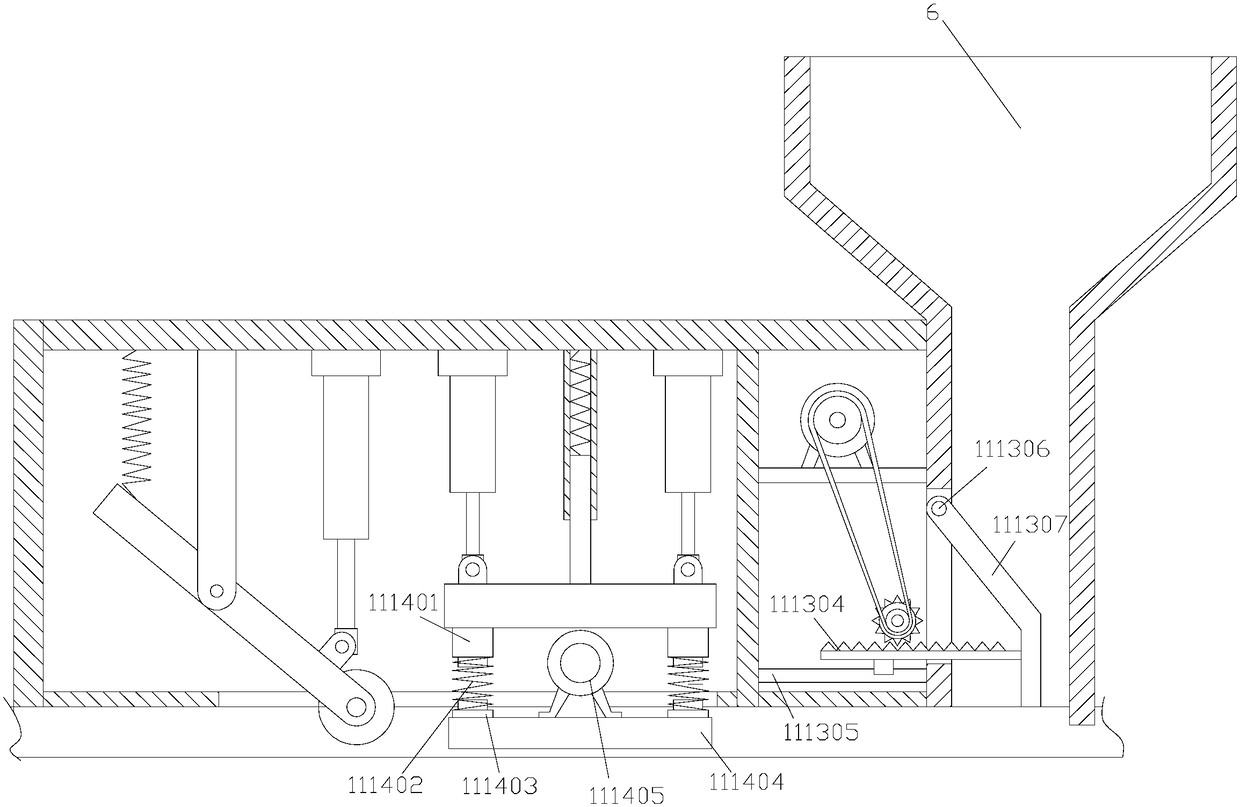

[0023] see Figure 1-Figure 4 , the present invention provides a new type of construction mortar plastering machine technical solution:

[0024]Its structure includes a base 1, a screw 2, a moving wheel 3, a rocking wheel 4, a processing box 5, a mortar hopper 6, a discharge pipe 7, a square hole 8, a rectangular opening 9, a partition 10, a plastering mechanism 11, and the screw 2 One end is vertically welded to the top of the moving wheel 3, and the other end is vertically installed in the middle of the bottom of the rocking wheel 4 by means of welding connection. The four corners of the base 1 are all provided with threaded holes, and the screw rod 2 runs through the threaded holes and Threaded connection, four moving wheels 3 are installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com