Truss type automatic wire take-up machine

A cable arranging machine and truss-type technology, which is applied in the field of truss-type automatic winding and arranging machines, can solve the problems of cluttered cable arrangement at both ends of the spool, and achieve a small footprint, little potential safety hazard, and a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

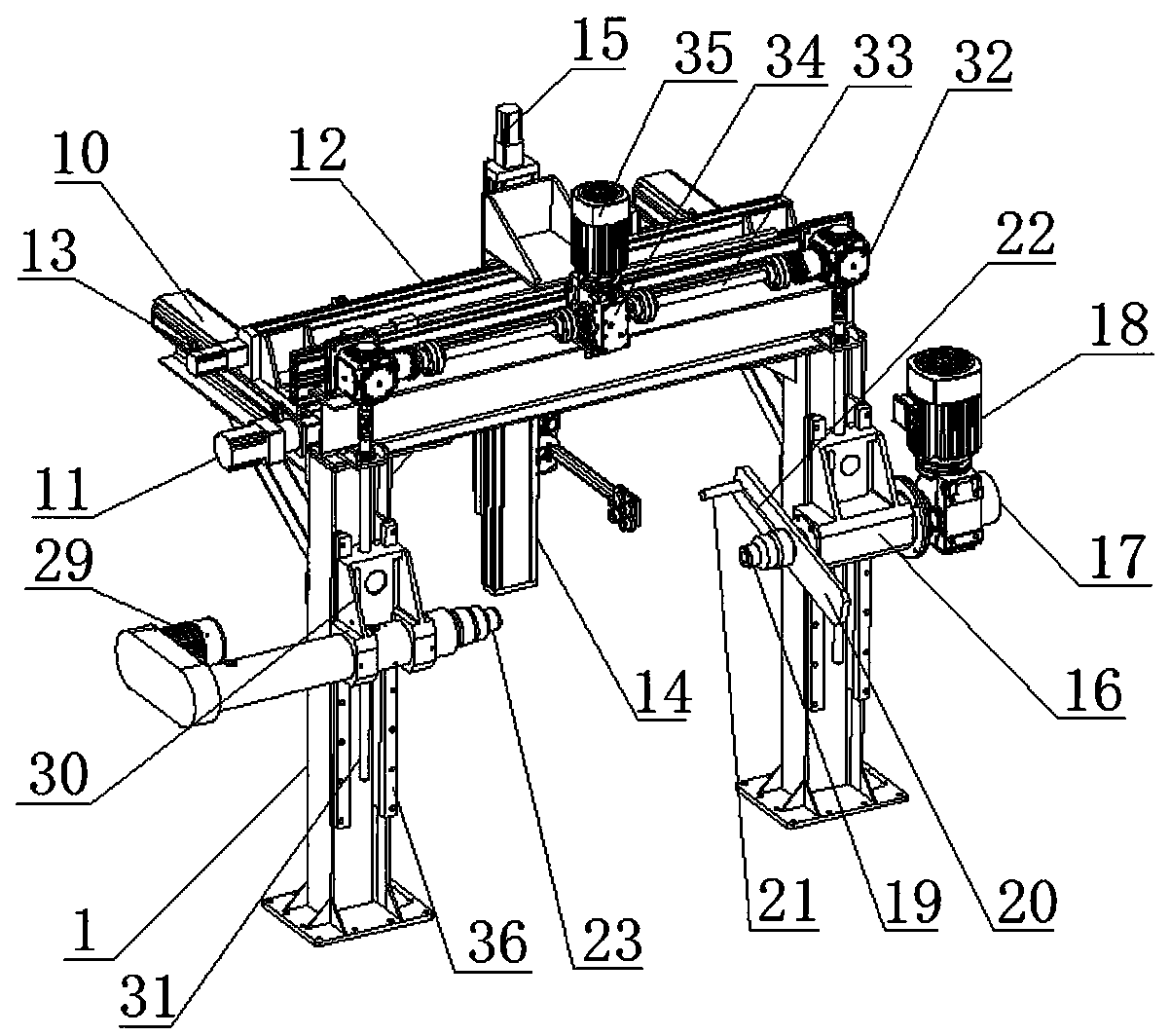

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0028] The three directions of the XYZ three-axis in this embodiment are defined as, the X-axis is the front-back direction of the truss, the Y-axis is the left-right direction of the truss, and the Z-axis is the vertical direction of the truss.

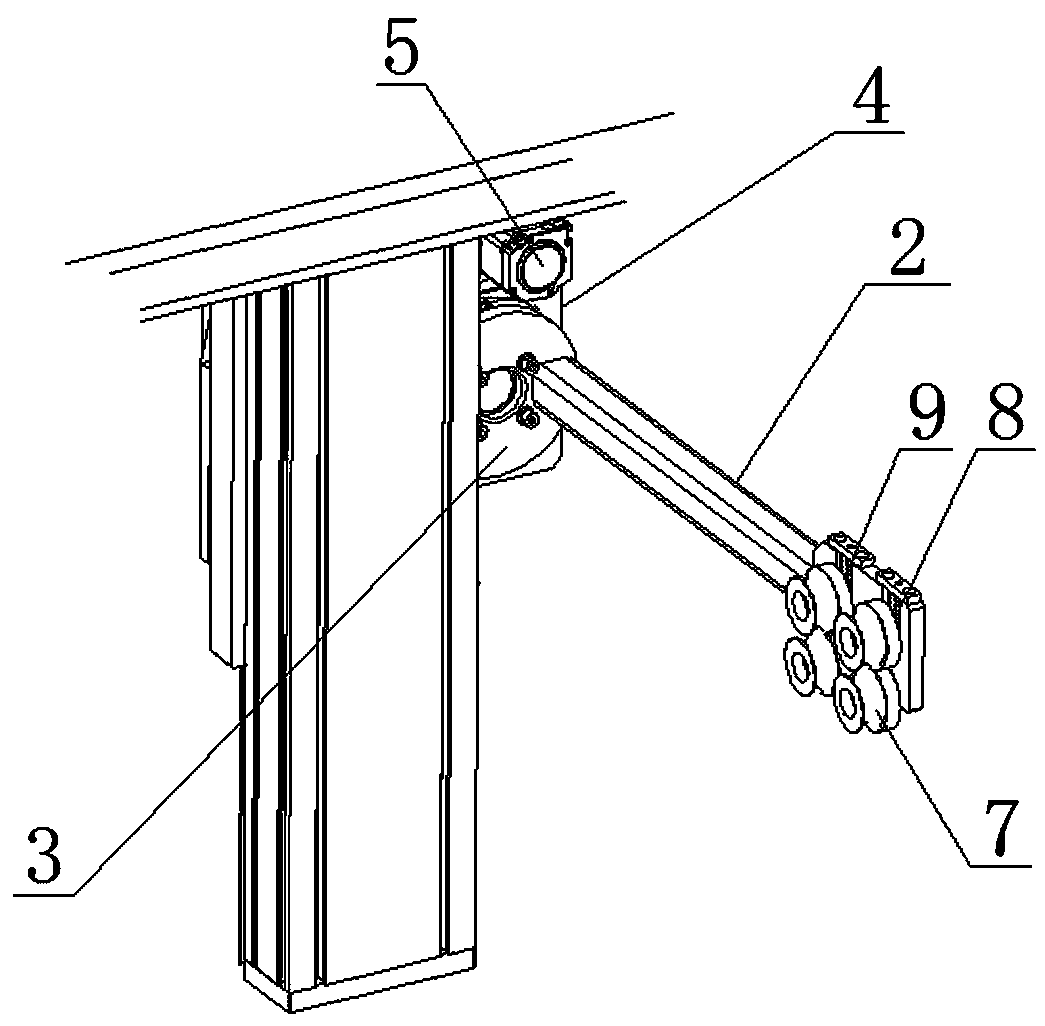

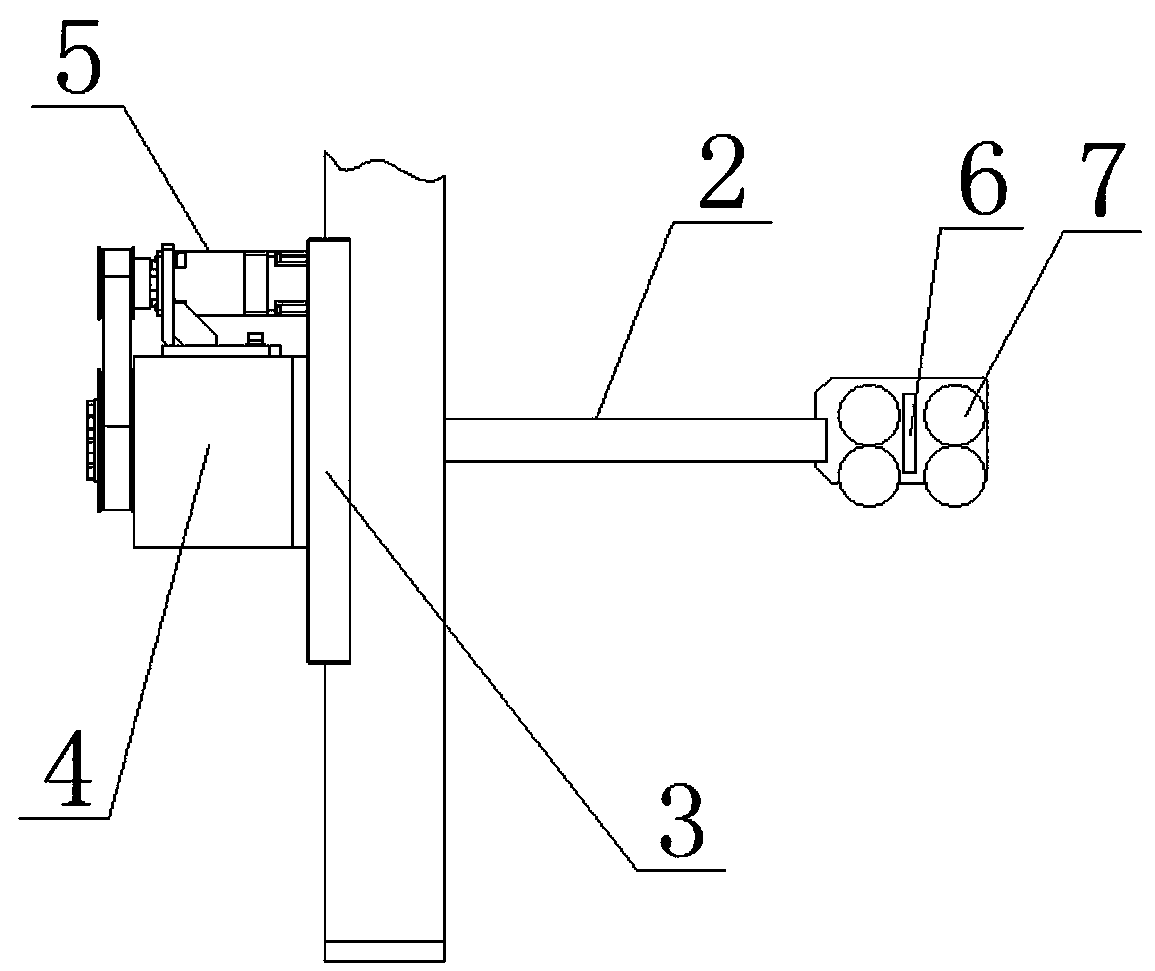

[0029] As shown in the figure, a truss-type automatic wire take-up and discharge machine of the present invention includes a truss 1 and a wire take-up mechanism and a wire discharge mechanism arranged on the truss. The wire discharge mechanism includes a three-axis drive mechanism, a wire discharge arm 2, and a turntable 3. Rotating base 4, rotating motor 5 and photoelectric sensor 6. The rotating base 4 is set on the three-axis driving mechanism and is driven by the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com