Liquid crystal light beam control device and manufacturing method

A beam control, beam technology, applied in optics, optical components, nonlinear optics, etc., can solve the problems of high manufacturing cost, poor beam intensity distribution, excessive and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

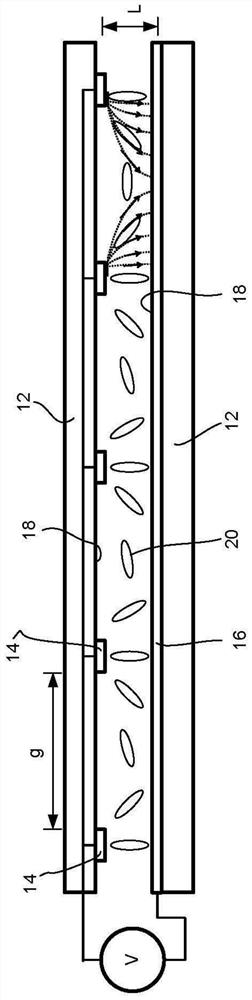

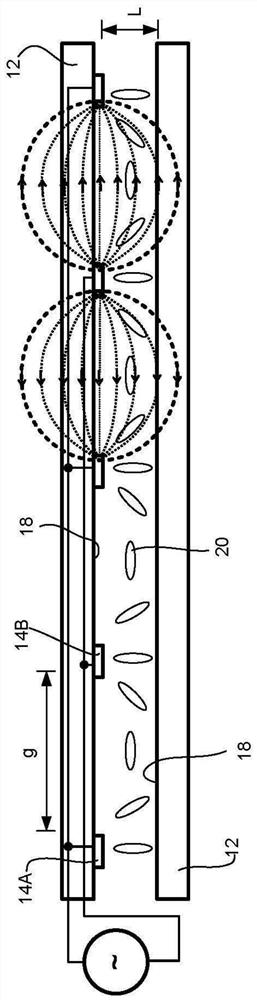

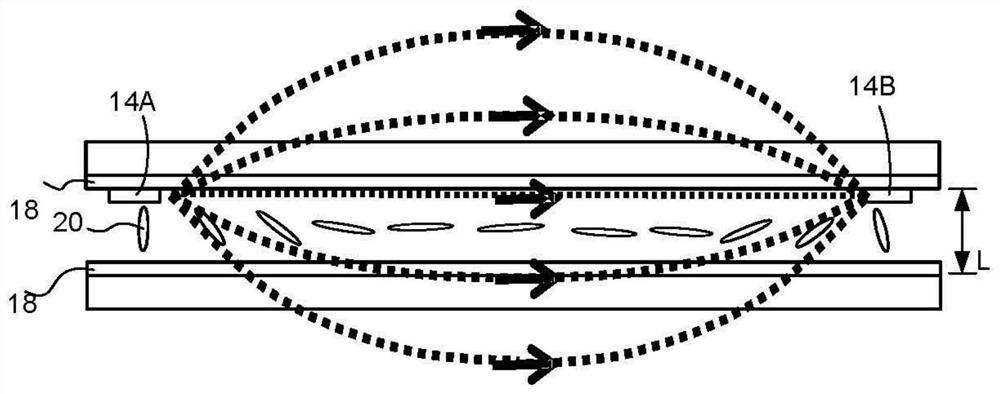

[0087] A beam steering device is an optical device that controls the (refracted) output beam of light, enabling beam divergence or direction (direction) control of said beam. Controlling beam divergence / convergence is a special case of beam steering to provide focus / defocus. Beam direction control can be used for beam steering purposes. Beam steering devices that provide a combination of beam spreading, beam divergence / convergence, or beam direction control are generally referred to herein as beam steering devices.

[0088] In liquid crystal beam steering devices, electric fields are commonly used to control the molecular orientation of liquid crystal material in an LC cell. The electric field can spatially modulate the optical aperture of the liquid crystal optics to spatially modulate the liquid crystal orientation. Changes in molecular orientation will affect the local refractive index of the LC material and can create a refractive index gradient of the LC material throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com