Shift device and method for securing shift device

A technology for equipment and shift shafts, which is applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems of cost fixation, anti-corrosion and anti-vibration measures, etc., to avoid corrosion and simplify The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

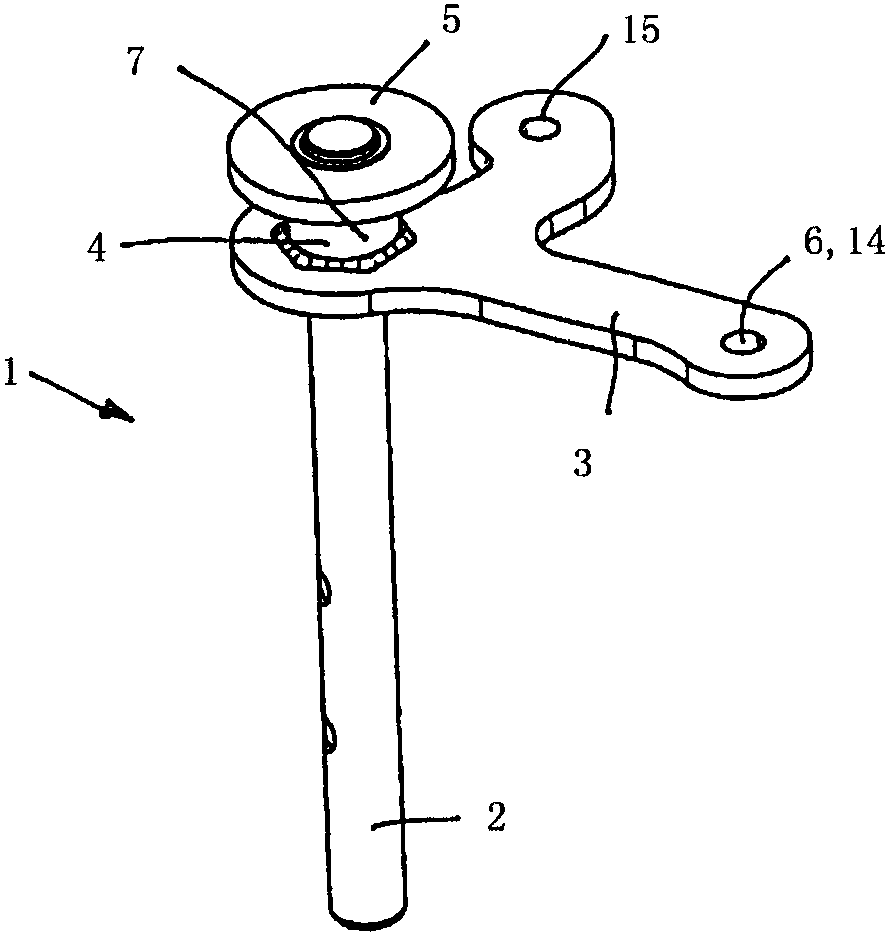

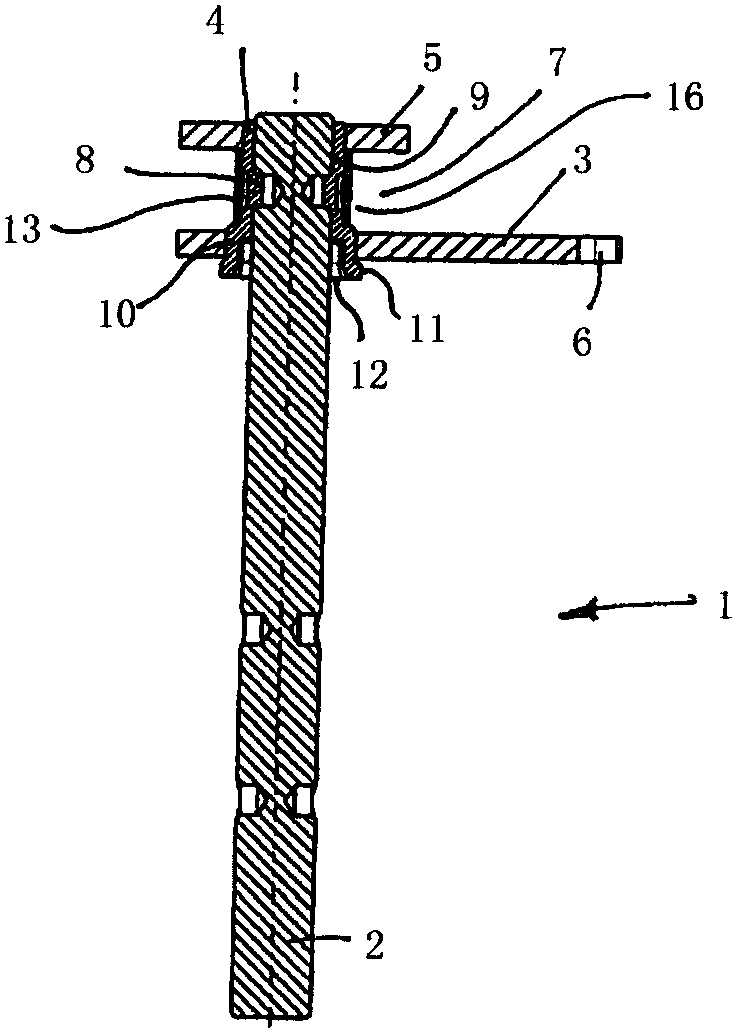

[0031] figure 1 The schematic diagram of FIG. 1 illustrates the design and function of a first variant of a shifting device 1 for a shift transmission or gearbox of a motor vehicle (not shown). The shifting device 1 has a shift shaft 2 of a transmission. The shifting shaft 2 is mounted rotatably and axially displaceably in a transmission housing, also not shown. The unit consisting of the selector lever 3 , the sleeve 4 or the disc 5 is fastened to the shift shaft 2 on the end side in a rotationally fixed manner. The selector lever 3 has at its free end a rod recess 6 for a ball head, on which a rod connection or a cable drive of a manual selector lever (not shown) can act in order to pivot The selector lever in turn rotates the selector shaft 2 by a defined rotational angle amount, which is necessary for changing gears.

[0032] The selector lever 6 has two arms arranged approximately perpendicular to each other. Angle α can also have an angle of 0°-360° depending on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com