Electrode for brain wave measurement

An electrode and brain wave technology, applied in the field of electrodes for brain wave measurement, can solve problems such as troublesome work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

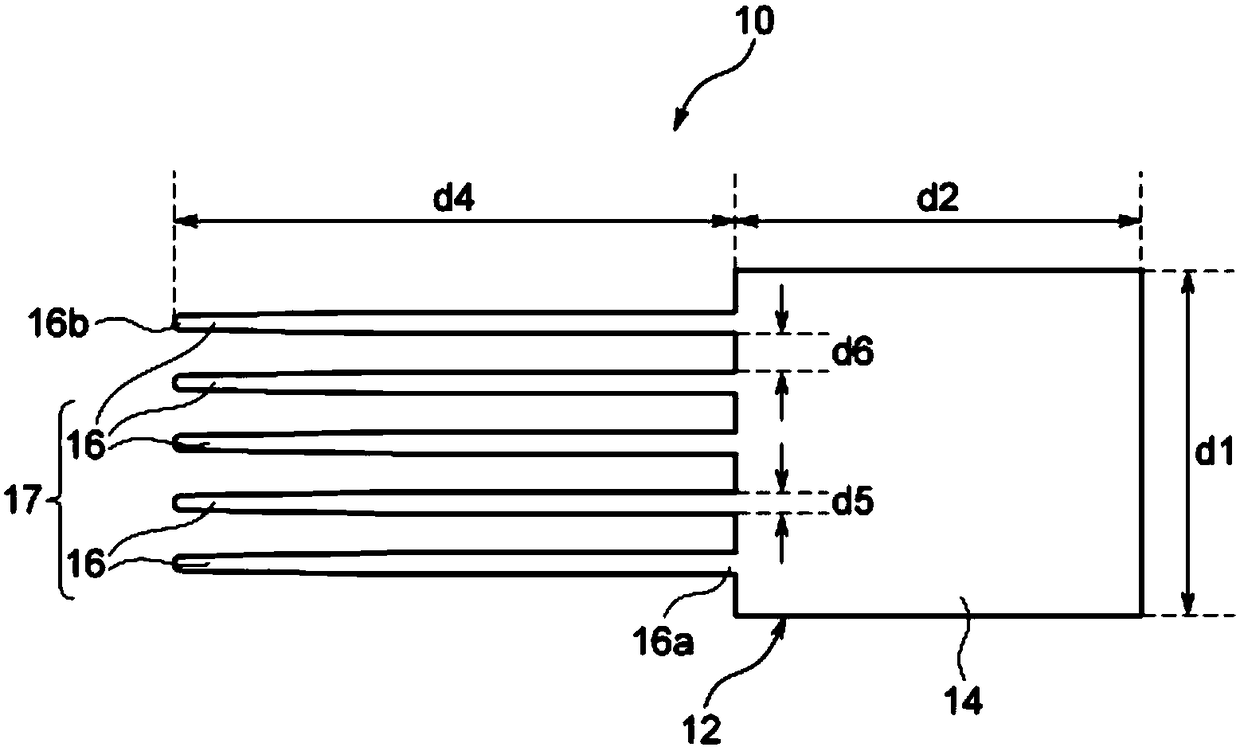

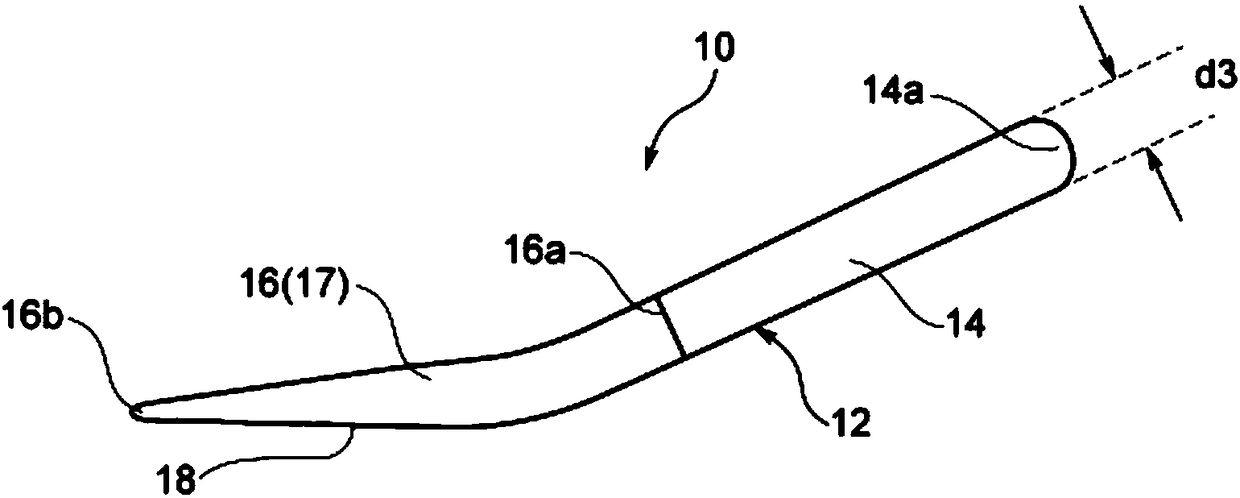

Embodiment 1

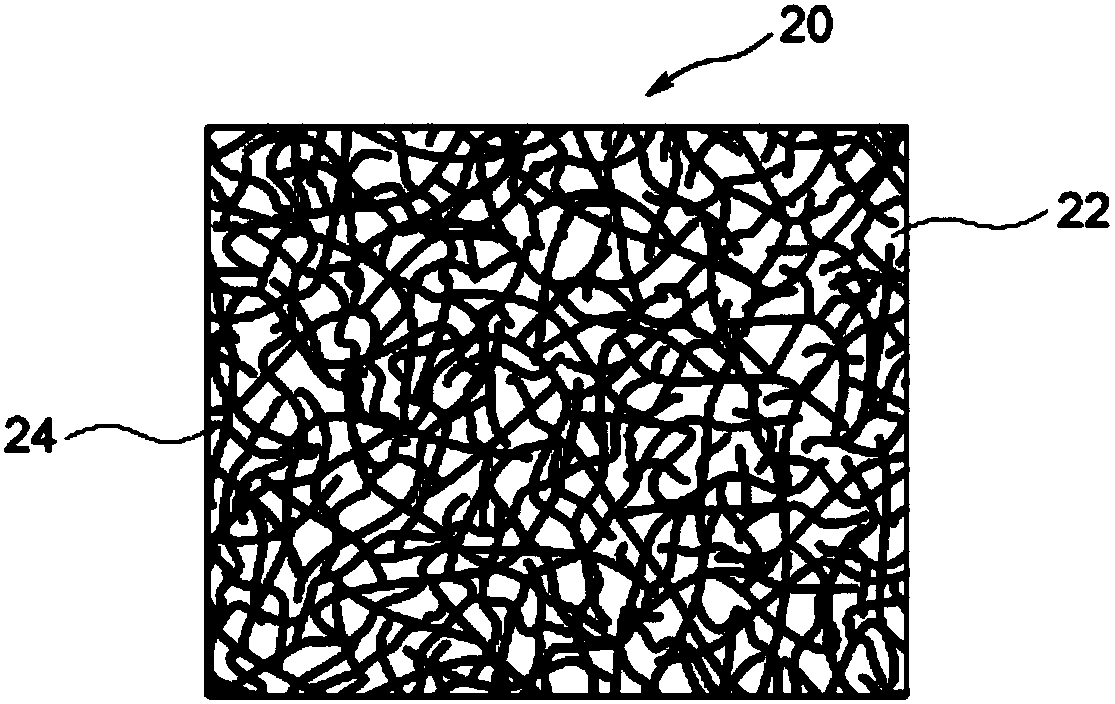

[0086] In this example, electrodes for electroencephalogram measurement were produced by pasting CNT-coated paper on a comb-shaped substrate, and their electrical characteristics were investigated. CNT-coated paper consists of a fiber base material and a structure formed by attaching CNTs to the surface of the fiber base material. Therefore, in the electrode for electroencephalogram measurement of Example 1, a structure having a network structure in which a plurality of CNTs are connected to each other is exposed on the surface of the comb-shaped base material.

[0087]

[0088] CNTs are produced by a general thermal CVD method using iron as a catalyst. The CNTs separated and dispersed with mixed acid and ultrasonic waves were taken out, neutralized with ammonia water, and washed with pure water. Finally, it was dried in an oven to obtain powdered CNTs.

[0089] Powdered CNTs were dispersed in DMF to produce a CNT dispersion. The concentration of CNTs in the dispersion li...

Embodiment 2

[0104] In the present embodiment, an electroencephalogram measurement electrode composed of a conductive comb-shaped base material is produced, and its electrical characteristics are investigated. The conductive comb-shaped base material is a CNT kneaded product obtained by molding a mixed material in which CNTs are kneaded in an elastomer as a base material into a comb shape. Therefore, the electrode for electroencephalogram measurement of Example 2 has a network structure in which a plurality of CNTs are connected to each other in addition to the surface of the comb-shaped base material.

[0105]

[0106] Samples of CNT kneaded products containing different concentrations of CNT were produced, and the relationship between CNT concentration and volume impedance was investigated. When producing a sample, first, CNTs and a base material were melt-kneaded by a twin-screw extruder, thereby producing a CNT-kneaded strand with a diameter of 0.3 cm. As the CNTs, CNTs obtained by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com