Sucker rod centering device capable of being conveniently dismounted and mounted

A technology for easy disassembly and assembly of sucker rods, applied in the direction of drill pipes, earthwork drilling, drilling equipment, etc., can solve the problems of high maintenance costs, cumbersome operations, high labor intensity, etc., and achieve extended service life, simple design structure, The effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

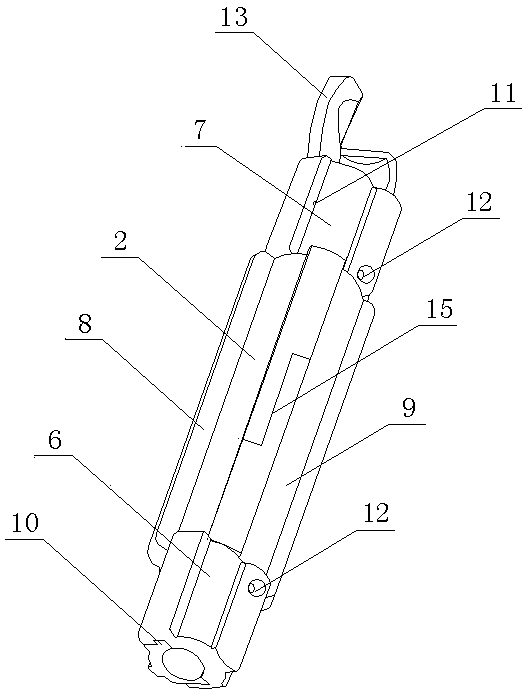

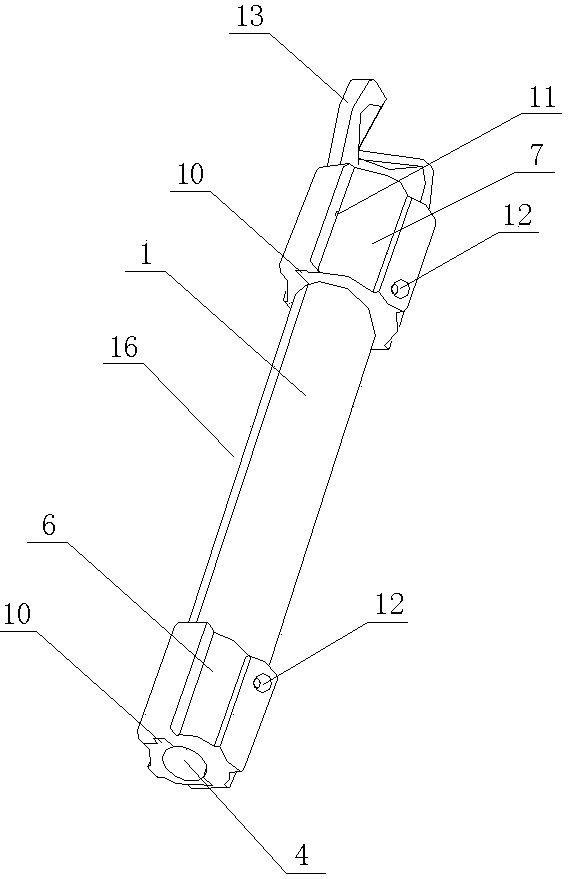

[0016] The convenient detachable sucker rod centralizer of the present invention is composed of a rod frame 1 and a wing barrel 2 . The rod frame 1 is a cylindrical pipe section formed by longitudinal insertion of two semicircular tile tubes 3, the inside of which is the sucker rod channel 4, the middle part is the frame rod 5 of the wing tube 2 with reduced diameter, and the lower end is The wing tube seat platform 6 and the upper end of the expanded diameter are the wing tube limiting pressure table 7 of the expanded diameter. The wing tube 2 is composed of two relatively snap-connected tile tubes 9 with longitudinal fins 8 on the outer wall, and the wing tube 2 is sleeved on the sleeve groove 16 in the middle section of the rod section of the rod frame 1 .

Embodiment 2

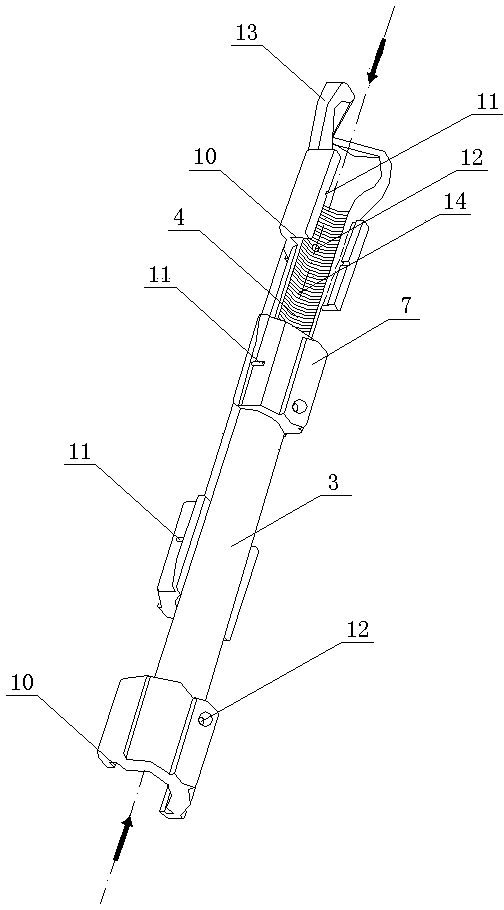

[0018] The convenient detachable sucker rod centralizer of the present invention is composed of a rod frame 1 and a wing barrel 2 . The rod frame 1 is a cylindrical pipe section formed by longitudinal insertion of two semicircular tile cylinders 3 with textures 14 that increase the frictional force on the inner surface, and the inside of the cylinder is the sucker rod channel 4, The middle section is the support bar 5 of the wing tube 2 with reduced diameter, the lower end is the wing tube seat platform 6 with expanded diameter, and the upper end is the wing tube limit press platform 7 with expanded diameter. The outer periphery of rod frame 1 between 7 forms sleeve groove 16. Said wing barrel 2 is composed of two relatively snap-fit tile barrels 9 with longitudinal fins 8 on the outer wall, and the wing barrel 2 is set on the fitting groove 16 . More than one longitudinal fin 8 is arranged on the outer periphery of the airfoil 2 , and the outer edge of each airfoil 8 protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com