Intelligent-driven self-healing anti-seepage layer of landfill and its self-healing anti-seepage method

A landfill, self-repair technology, applied in construction, infrastructure engineering, protection devices, etc., can solve problems such as acid leachate pollution, and achieve the effect of overcoming leachate pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, innovative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

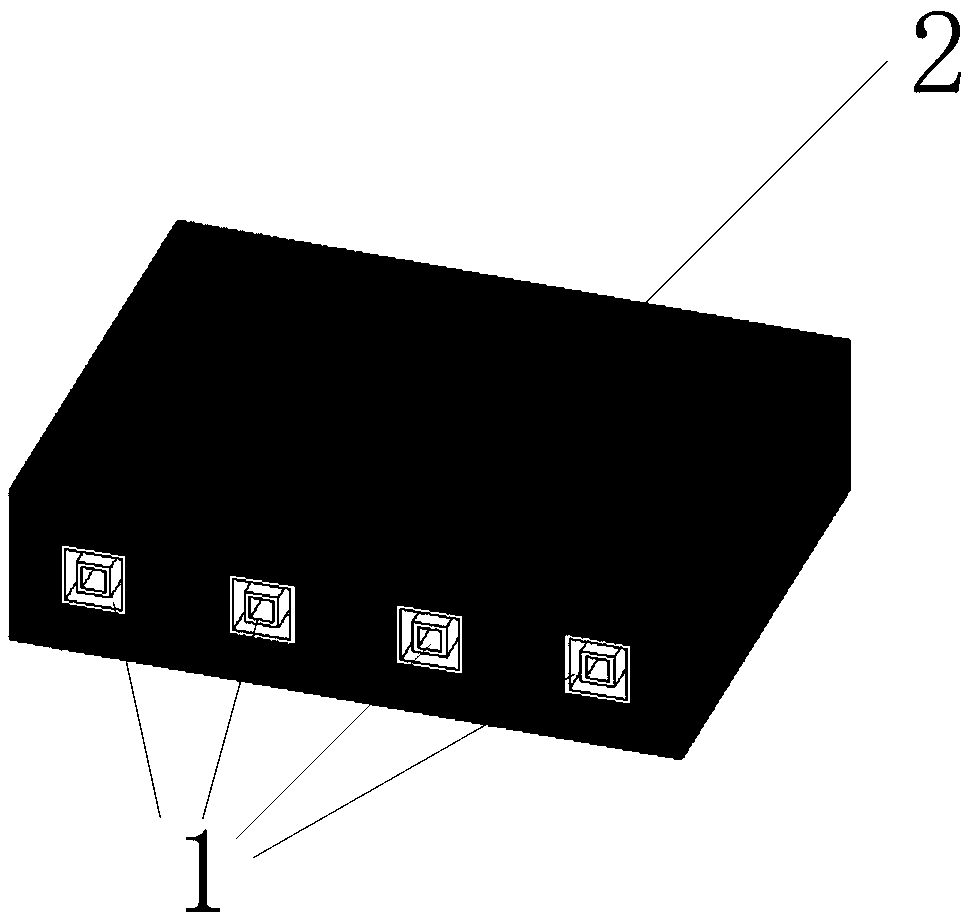

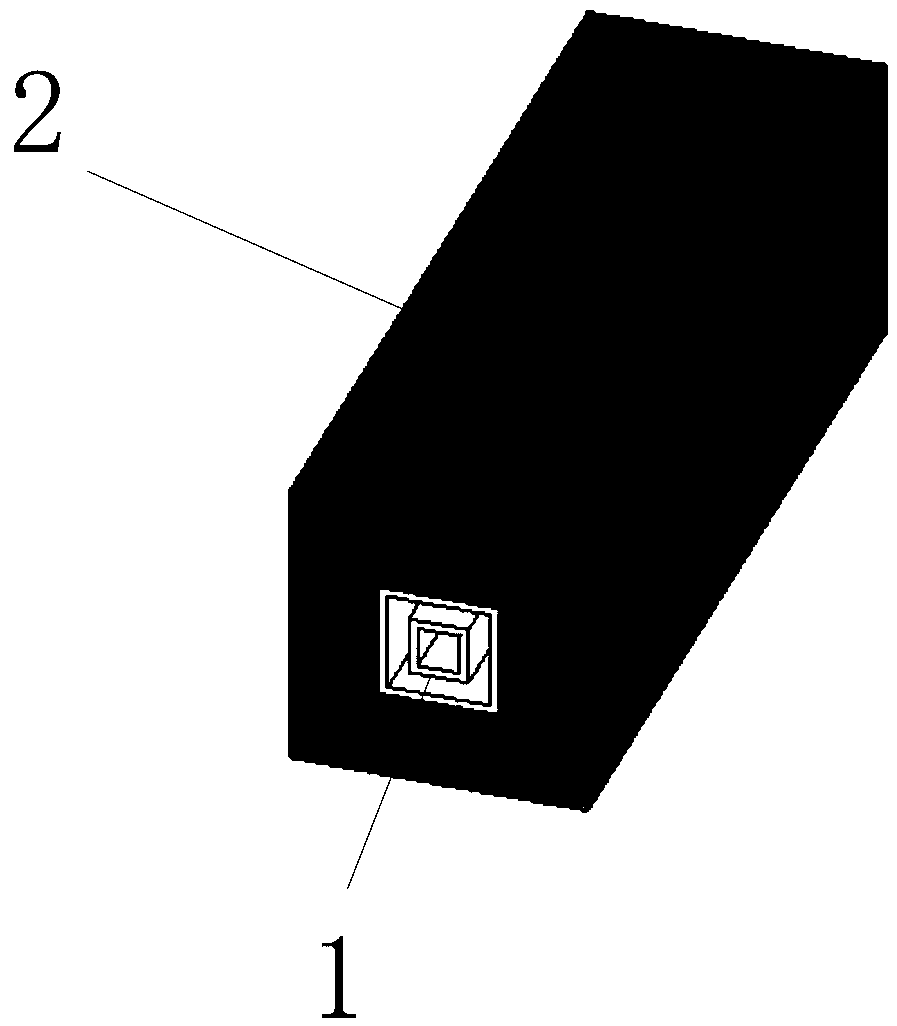

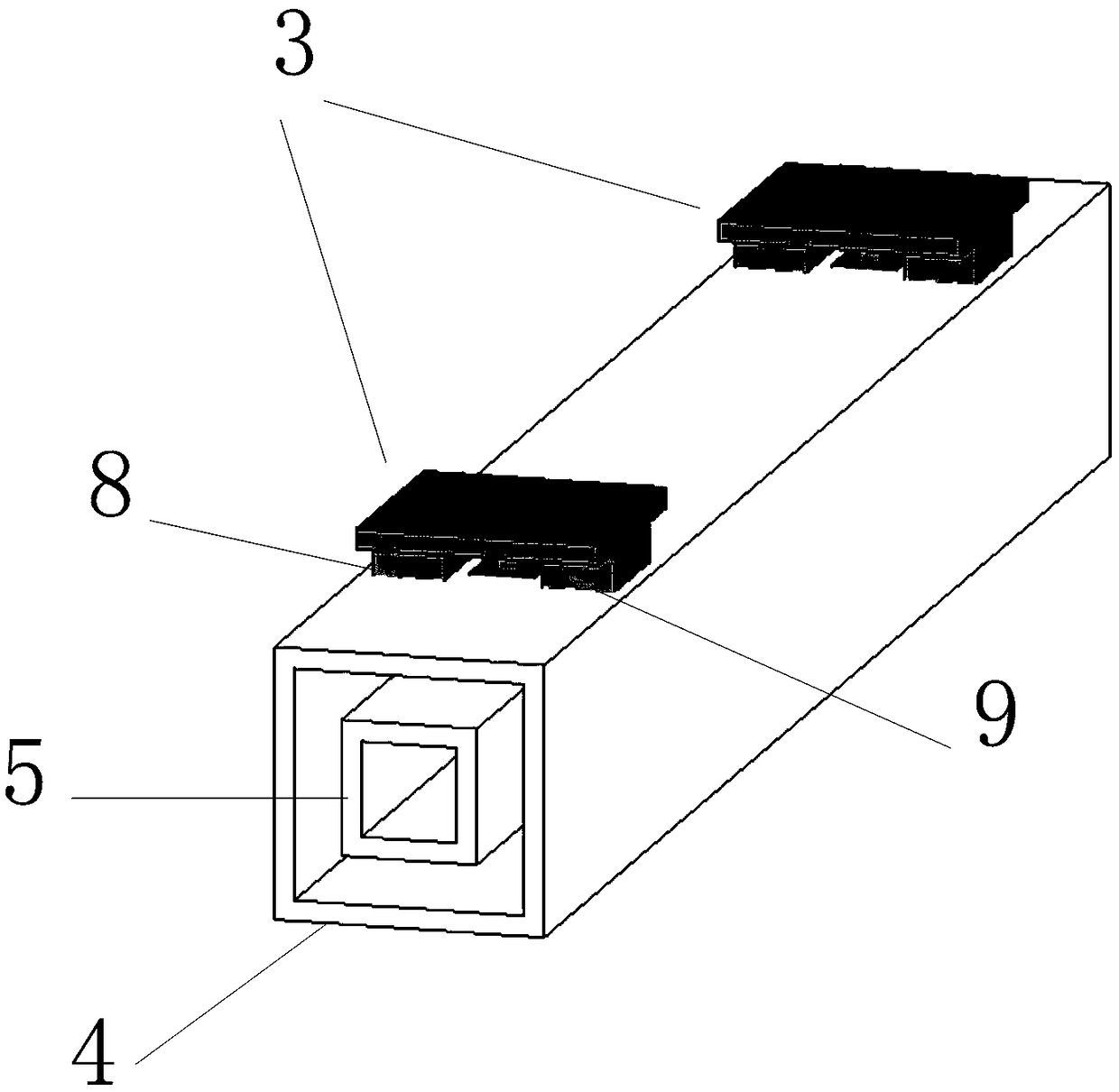

[0027] Such as Figure 1-5 An anti-seepage layer of an intelligently driven self-repairing landfill includes several self-repairing rods 1 and an anti-seepage base 2; the self-repairing rods 1 are distributed in the anti-seepage base 2; the self-repairing rods 1 include Several intelligent drive switches 3, concentric first hollow rod 4 and second hollow rod 5, the second hollow rod 5 is located inside the first hollow rod 4, and the two ends of the first hollow rod 4 and the second hollow rod 5 are sealed , the space between the first hollow rod 4 and the second hollow rod 5 is filled with a repair solution 6, the repair solution 6 can be an alkaline silica sol, the second hollow rod 5 is filled with a liquid 7 that stimulates the repair solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com