Prediction method of workpiece surface form based on side milling machining

A technology of surface topography and workpiece surface, which is applied to metal processing machinery parts, metal processing equipment, milling machine equipment, etc., can solve problems such as low efficiency and complex calculation, so as to improve work efficiency, high reliability, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the accompanying drawings and examples.

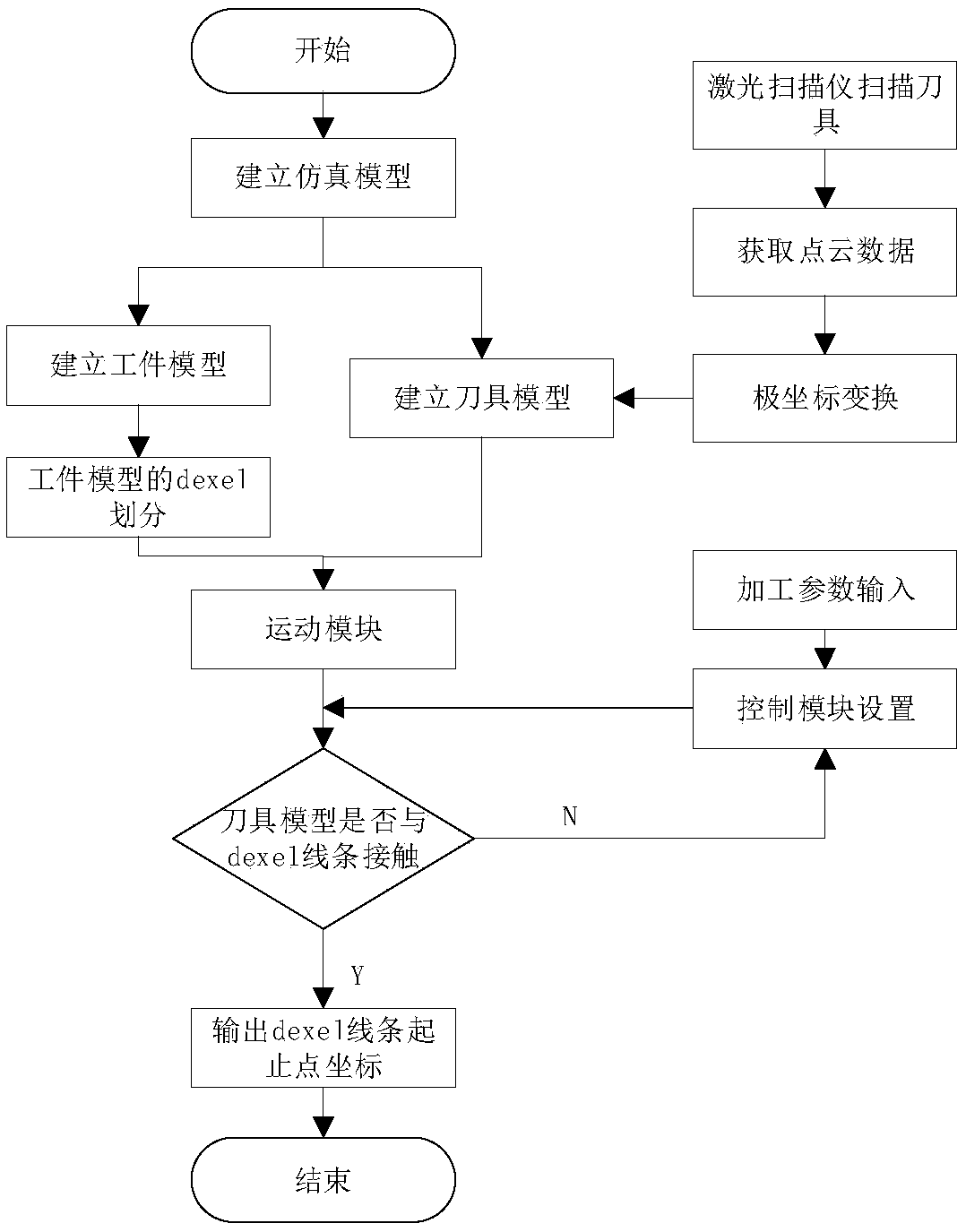

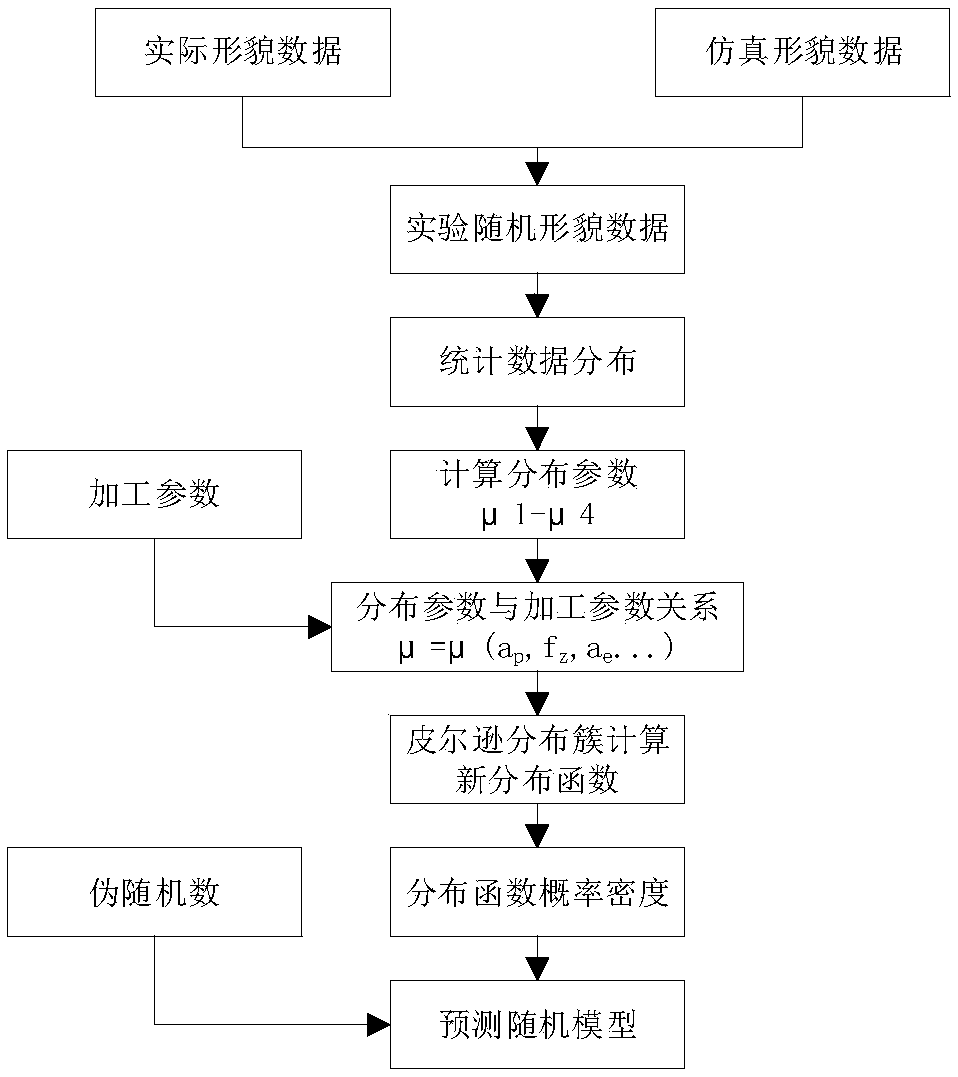

[0044] This embodiment provides a method for predicting the surface topography of workpieces based on side milling, see the attached figure 1 and Figure 4 , the specific steps are as follows:

[0045] The first step is to carry out side milling on the workpiece through the tool, and measure the surface topography data of the workpiece during real-time processing through the contact profiler, see the attached Figure 5 ;

[0046] The second step is to establish the simulation model of the side milling of the workpiece, including: workpiece model, tool model, control module, motion module and input and output module;

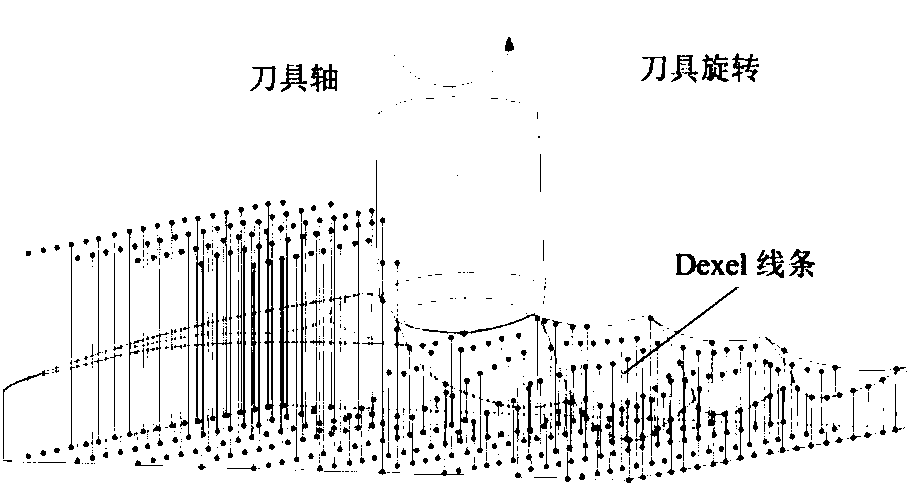

[0047] The workpiece model is obtained by simulating the workpiece in the first step; the workpiece model is located in the workpiece coordinate system, and the workpiece coordinate system is used to locate the position of the workpiece mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com