Automobile left and right side body inner plate front assembly clamp

A side wall inner panel, left and right technology, which is applied in the field of automobile left and right side wall inner panel front assembly fixtures, can solve the problems that affect the efficiency of production and processing, unqualified inspection, and difficulty in ensuring overall accuracy, etc., and achieve high space utilization. Guaranteed accuracy, improved efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

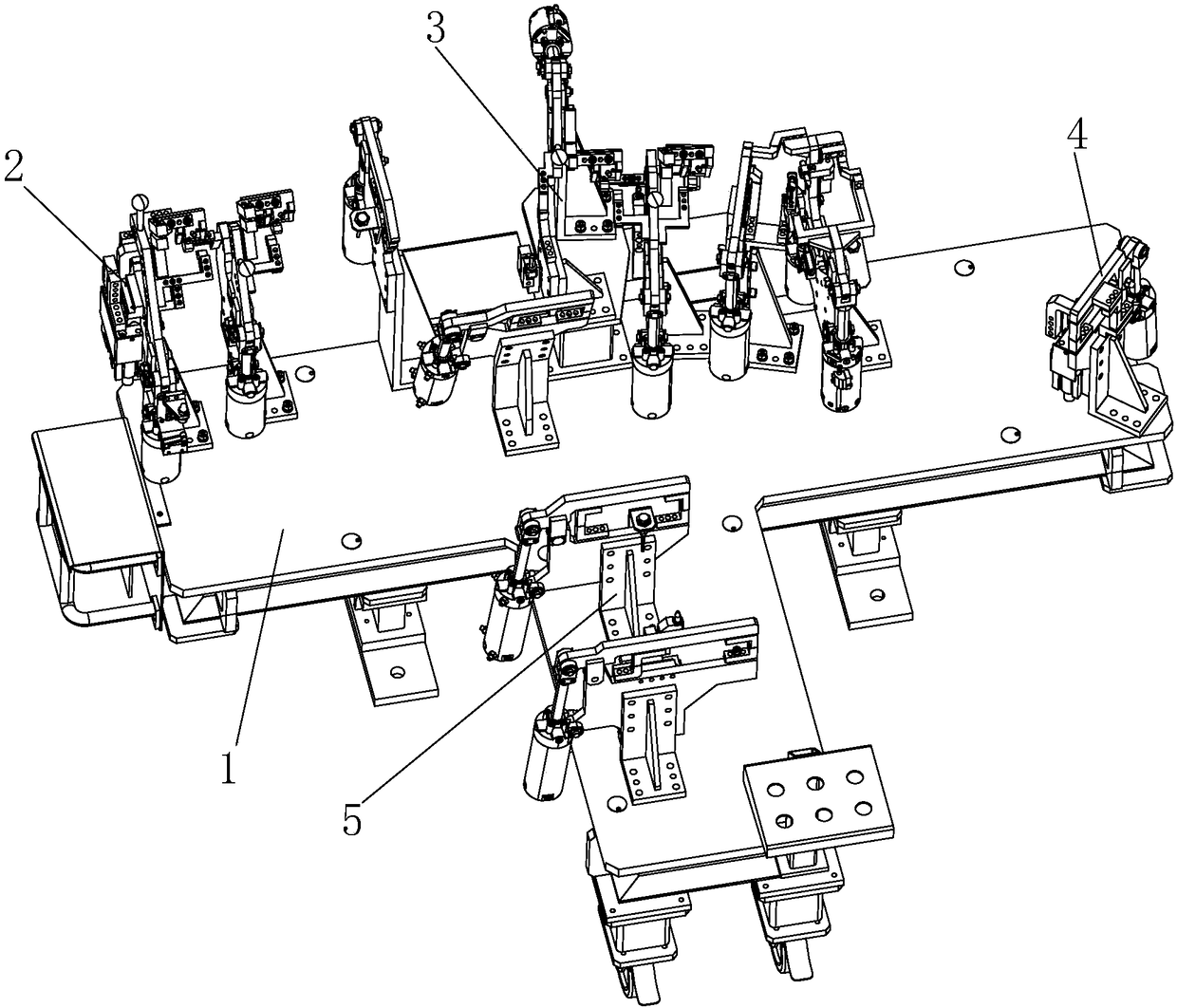

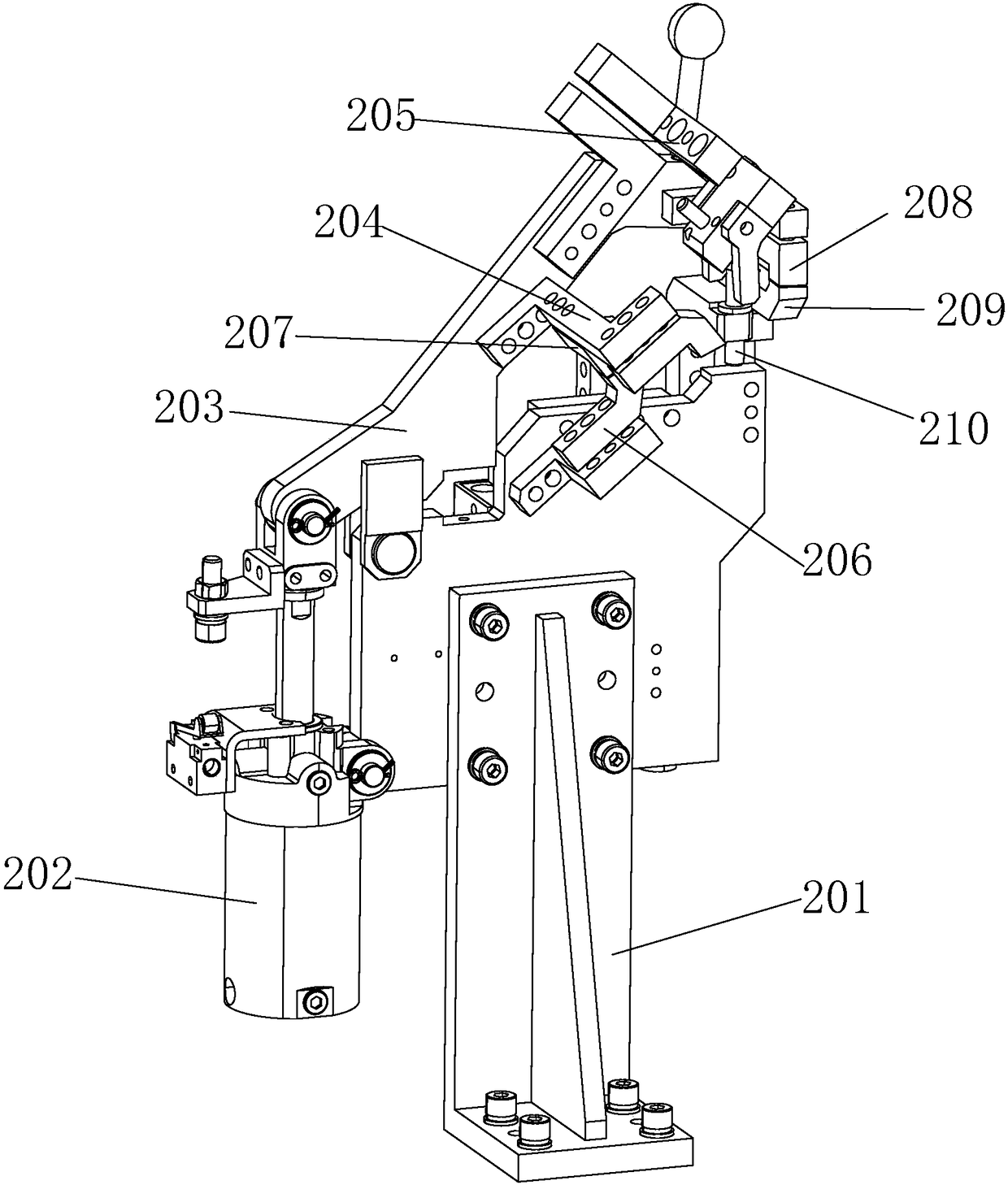

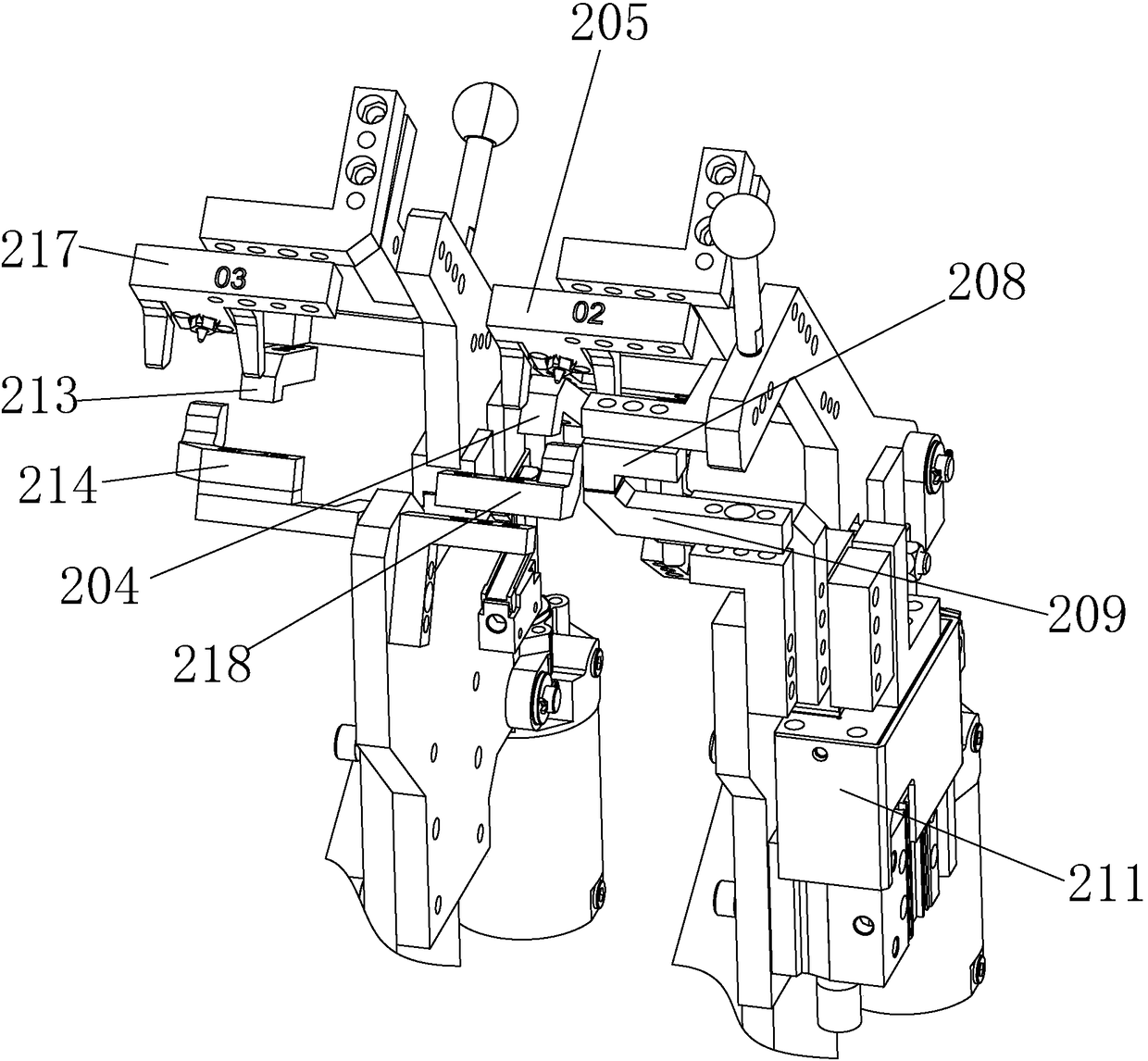

[0035] Such as Figure 1 to Figure 12 As shown, a front assembly fixture for the left and right side panels of an automobile includes a workbench 1, and the upper end of the workbench 1 is sequentially modularized from left to right with a left positioning and clamping tool 2 and a middle combined clamping Tooling 3, right side pressing tooling 4, the front part of described workbench 1 is equipped with tail clamping tooling 5. The invention has a reasonable structural design, uses one fixture to realize the positioning and clamping of all parts of the front assembly of the left and right sides of the automobile, and solves the problems of the traditional multi-process, multi-station, and multiple clamping and positioning methods The problems of complexity, low precision, and low effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com