A recovery method of extractant in high-viscosity coal-based oil residue raffinate

A recovery method and technology for coal-based oil, applied in the field of coal chemical industry, can solve the problems such as the inability to exert the unique advantages of high added value of heavy oil and asphalt substances, and achieve the effects of easy implementation, reduced evaporation temperature, and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

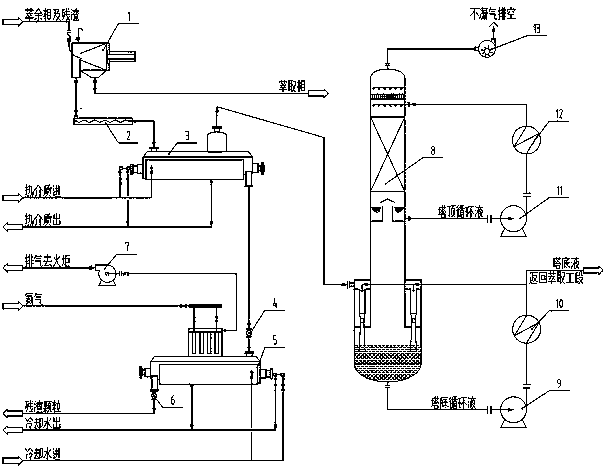

[0024] Such as figure 1 Shown, the recovery method of extractant in a kind of high-viscosity coal-based oil residue raffinate may further comprise the steps:

[0025] (1) The raffinate phase and residue are sent to the centrifuge 1 for solid-liquid separation, and the extract phase and the viscous solid phase with a viscosity of 8000-10000mPa·s and a washing oil content of 30-45% are obtained respectively; The washing oil of high-quality oil and bituminous substances, the extraction phase enters the next process for further separation to obtain products of different grades.

[0026] (2) The viscous solid phase is fed into the film dryer 3 from the feeding system 2 by gravity; at the same time, the central axis and shell of the film dryer 3 are fed with a heating medium for indirect heating. The heating medium transfers heat to the material through the hollow heat shaft, blades and jacket of the dryer, the temperature of the material rises, and the volatile components graduall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com