Frame type greenhouse capable of providing convenience for picking

A frame-type and side-frame technology, which is applied to harvesting machines, greenhouse cultivation, climate change adaptation, etc., can solve problems such as delays in production time, lumbar spine injuries of pickers, and unfavorable agricultural production, so as to protect the health of the spine , Low manufacturing cost, the effect of reducing the total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

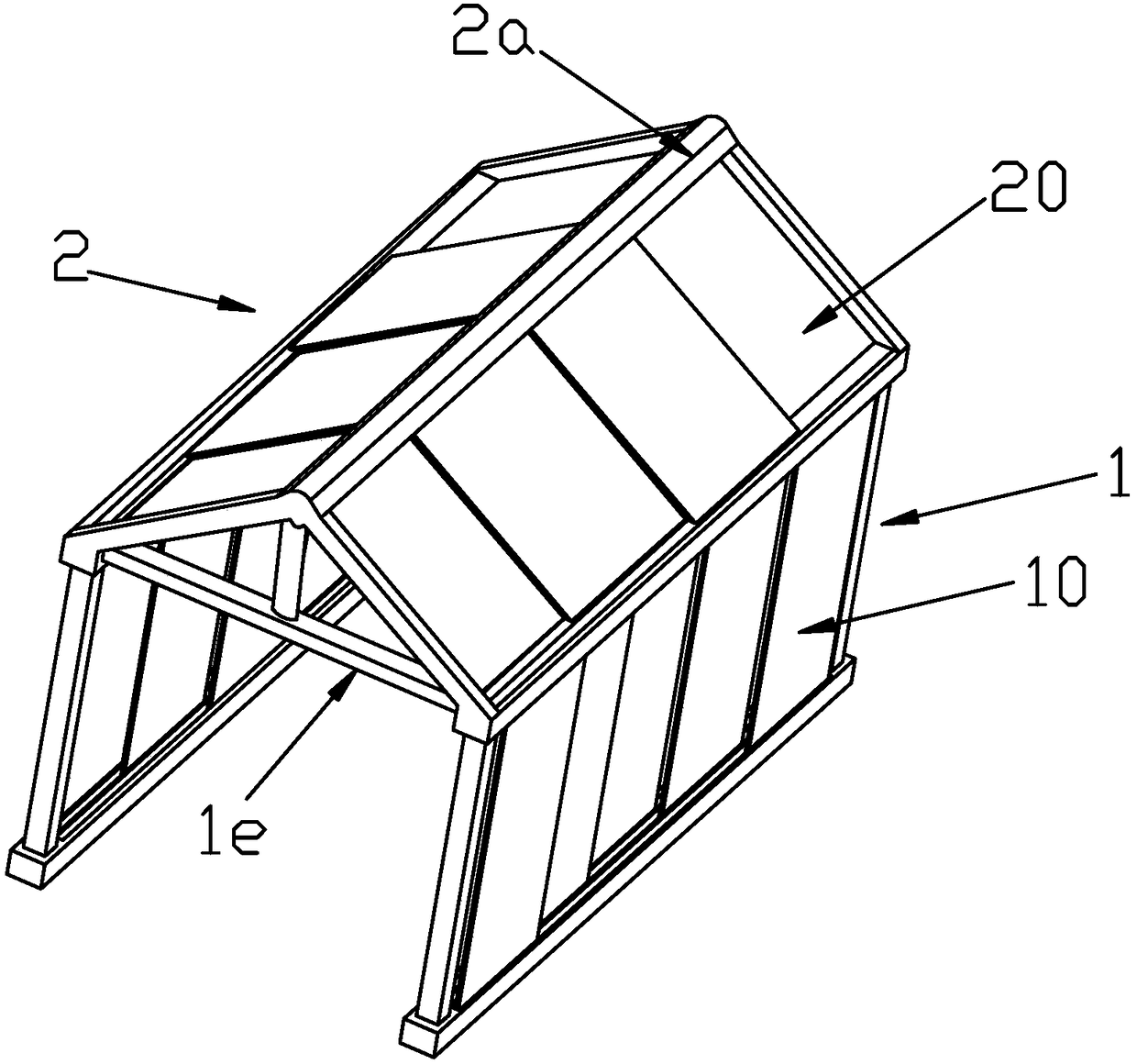

[0027] refer to Figure 1 to Figure 7 The shown frame-type greenhouse for easy picking mainly includes two side frames 1 arranged in parallel. The side frames 1 are vertically arranged in a rectangular frame structure, surrounded by an upper beam 1a, a lower beam 1b, a front column 1c and a rear column 1d. Formed, wherein the front column 1c and the rear column 1d are telescopic structures, similar to the lifting structure of an umbrella handle or an electric fan, which can be adjusted for lifting and can be locked.

[0028] Two top frames 2 are fixedly supported at the ends of the two side frames 1, and the two top frames 2 are arranged symmetrically along the middle line of the two side frames 1, and the two form an isosceles triangle structure. The top frame 2 consists of top beams 2a, The upper crossbeam 1a, the front slant beam 2b and the rear slant bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com