Heightening device for crane

A crane and side plate technology, applied in the field of crane heightening devices, can solve the problems of high cost, high requirements for hydraulic equipment, and increased lifting height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

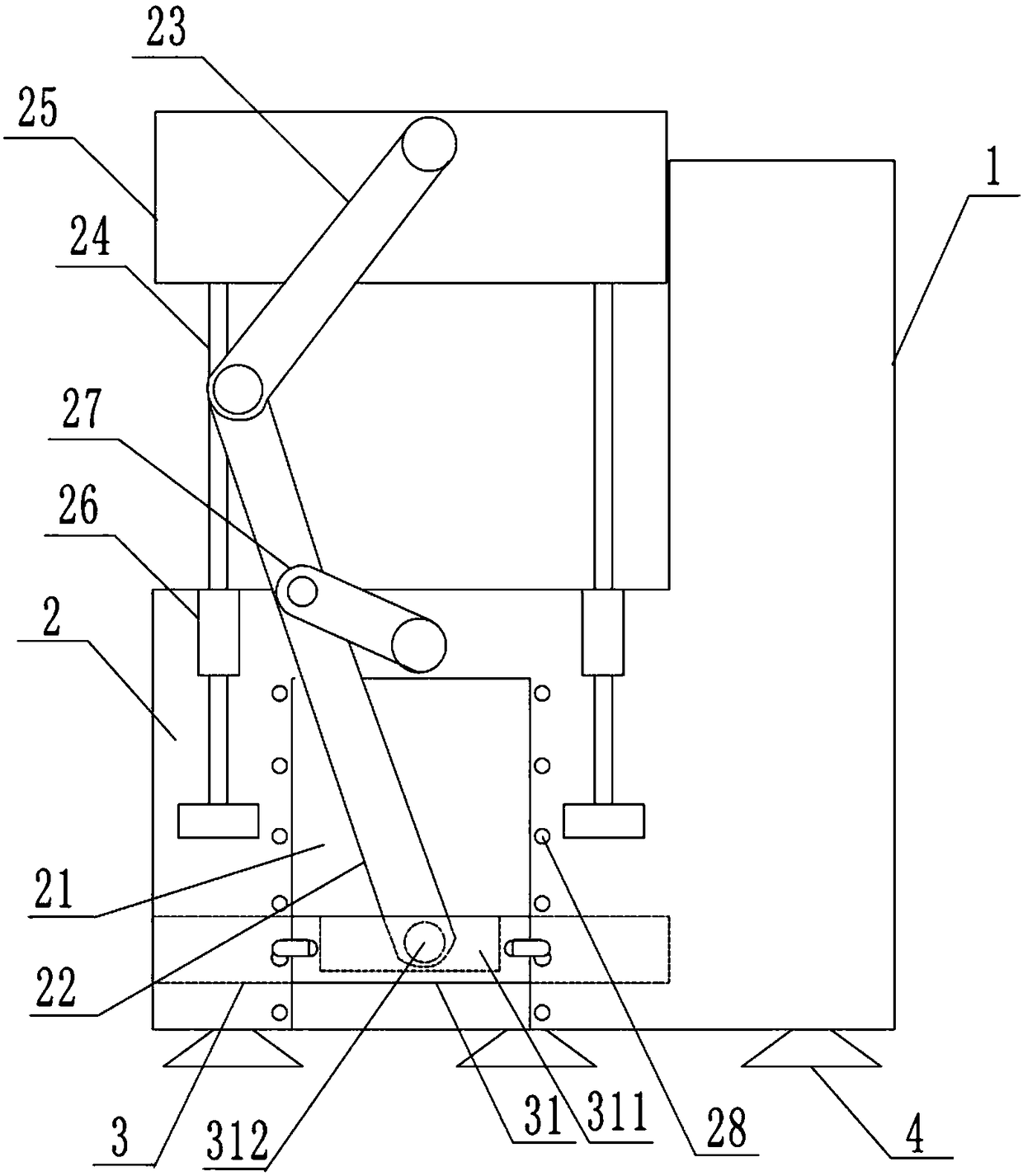

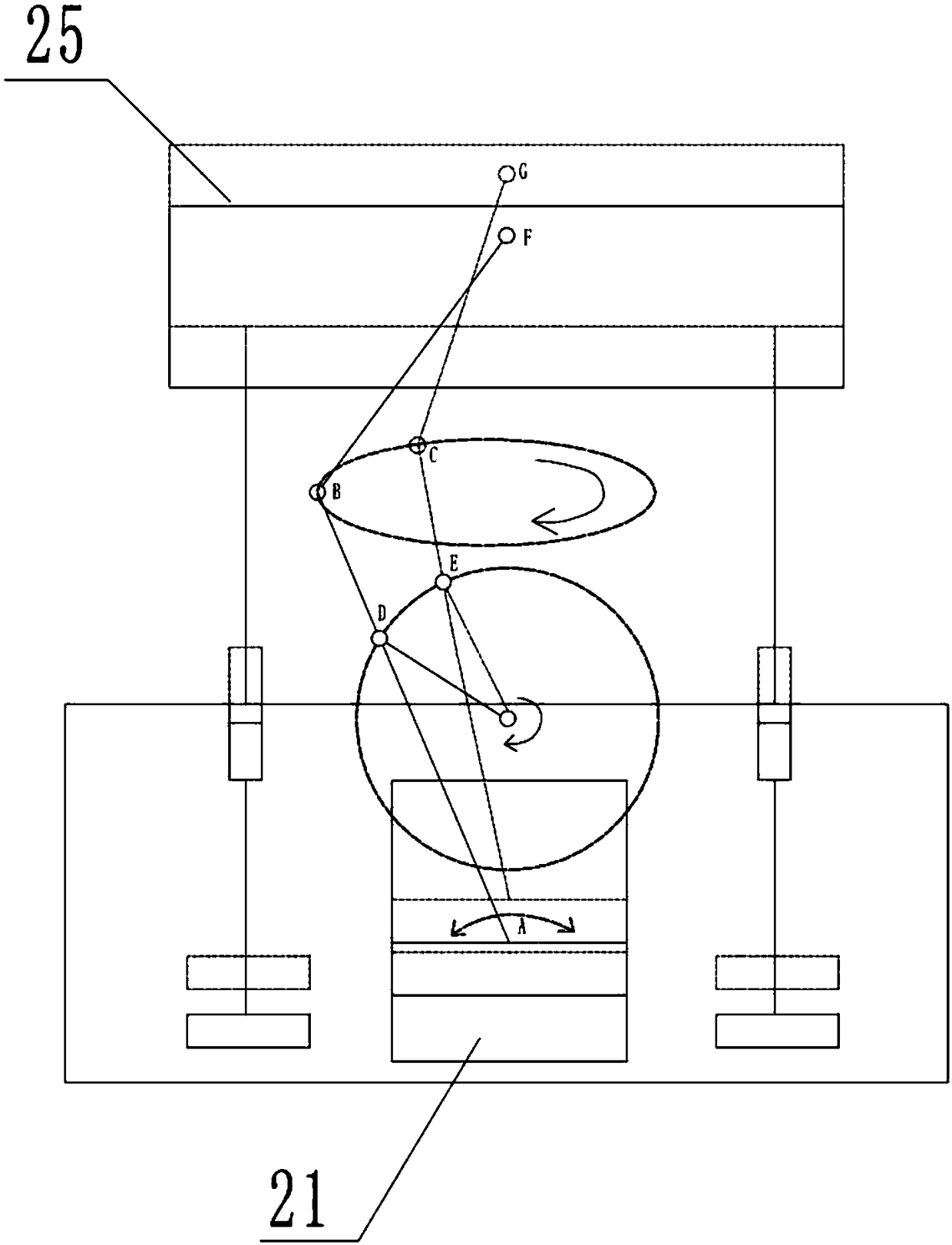

[0020] The reference signs in the accompanying drawings of the description include: back plate 1, strip groove 11, side plate 2, chute 21, swing rod 22, push rod 23, slide rod 24, baffle plate 25, limit shaft 26, rotation rod 27. Positioning hole 28, bottom plate 3, sliding block 31, swing groove 311, fixed shaft 312, suction cup 4, bar body 5, positioning column 51.

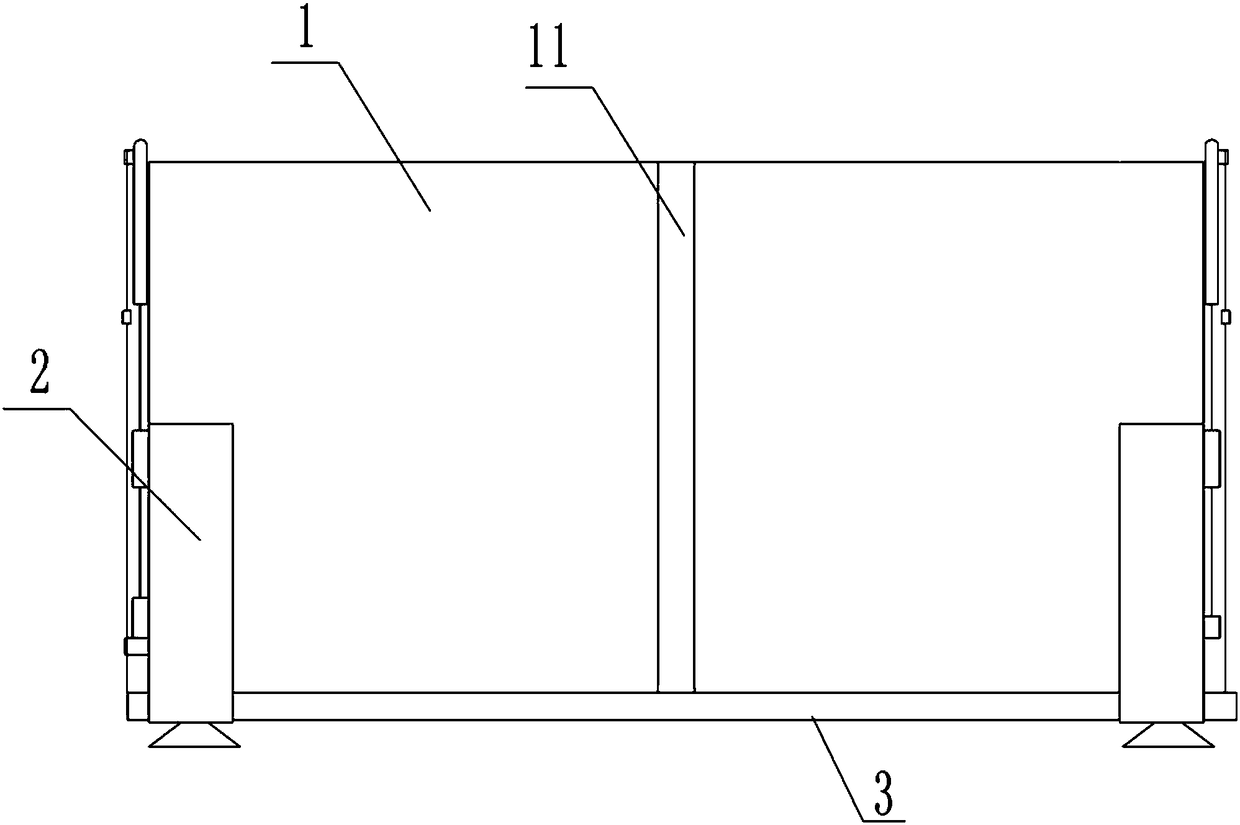

[0021] Such as figure 1 and figure 2 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0022] The crane heightening device comprises a backboard 1 and two sideboards 2 fixedly connected to both sides of the backboard 1, and the side view of the backboard 1 and the sideboards 2 is L-shaped. A bottom plate 3 is slidably connected between the two side plates 2; the side plates 2 are provided with chute 21, swing bar 22, push bar 23, slide bar 24, baffle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com