Cloth rolling machine

A cloth rolling machine and material rolling technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of excessive cloth rolling speed, uneven fabric, fabric wrinkles, etc., and achieve a simple overall structure, Ensure smooth and uniform rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

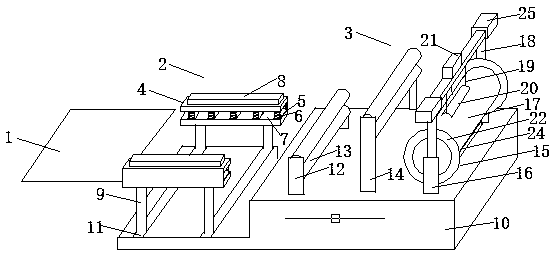

[0018] Attached below Figure 1-4 The structure, principle and working process of the present invention will be further described with specific embodiments, but the protection scope of the present invention is not limited thereto.

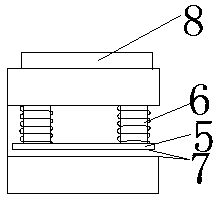

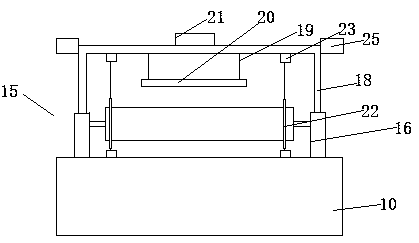

[0019] A cloth rolling machine, including a conveyor belt 1, a front positioning device 2 and a rear coiling device 3 arranged in sequence from left to right, the front positioning device 2 includes two positioning splints 4 with the same structure opposite to each other , the positioning splint 4 is "⊏" shape, the positioning splint 4 includes an upper end splint, a lower end splint and a connecting plate connecting the upper end splint and the left side of the lower end splint, and the bottom of the upper end splint is parallel to the The upper end splint is connected with several pressing plates 5, and the pressing plate 5 is a cuboid sheet structure, and the two ends of the pressing plate 5 are respectively connected to the bottom surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com