Abrasive flow machining die for uniform polishing of inner wall of cross-hole workpiece and calculating method of cores of abrasive flow machining die

A cross-hole and abrasive flow technology, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, machine tools suitable for grinding workpiece edges, etc. Problems such as equal margin and uniform polishing have not been realized, so as to ensure the polishing quality and improve the polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The specific implementation manners of the present invention will be further described below in conjunction with technical solutions, specific embodiments and accompanying drawings.

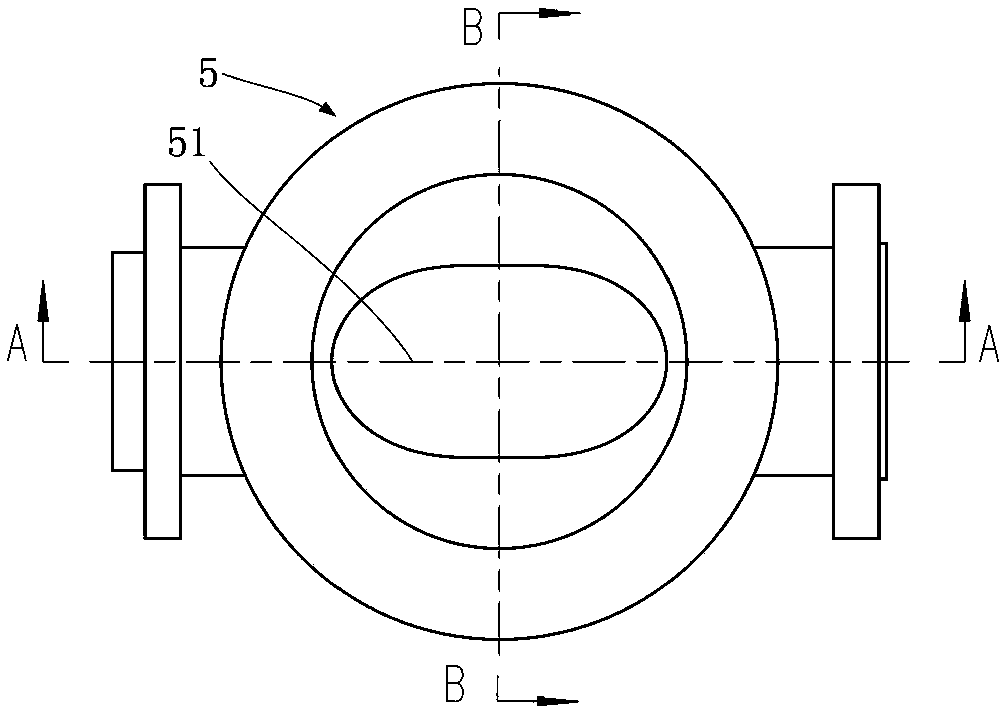

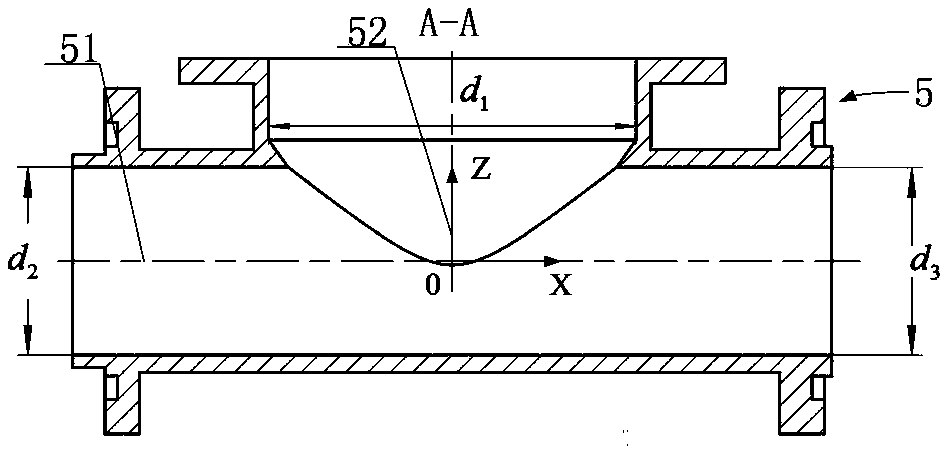

[0067] like figure 1 Shown is the structure of the uniform polishing mold with a cross-shaped cross-hole workpiece abrasive grain flow and the flow of the abrasive medium. In this embodiment, a "T"-shaped cross-hole part is used as the cross-hole workpiece 5. Its structure is as follows Figure 2-4 shown. designed as Figure 5-13 A "T" shaped cross-hole workpiece inner wall abrasive flow uniform polishing mold is shown, including the flow channel control unit A2, the flow channel control unit B3, the flow channel control unit C4 and the sealing device;

[0068] The number of the flow channel control unit is the same as the number of orifices of the cross hole workpiece 5, i.e. three; each flow channel control unit corresponds to the orifice of a cross hole workpiece 5; the flow channel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com