Apparatus for ultrasonic-assisted machining

An auxiliary processing and ultrasonic technology, applied in the field of processing equipment, can solve problems such as unfavorable automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to solve the above-mentioned problems, the present invention provides an ultrasonic auxiliary processing device. The resonant rod has an unconstrained design relative to the processing tool / electrode, which can effectively achieve the function of ultrasonic vibration and tool / electrode exchange for automatic production, which is in line with industrial applications. need.

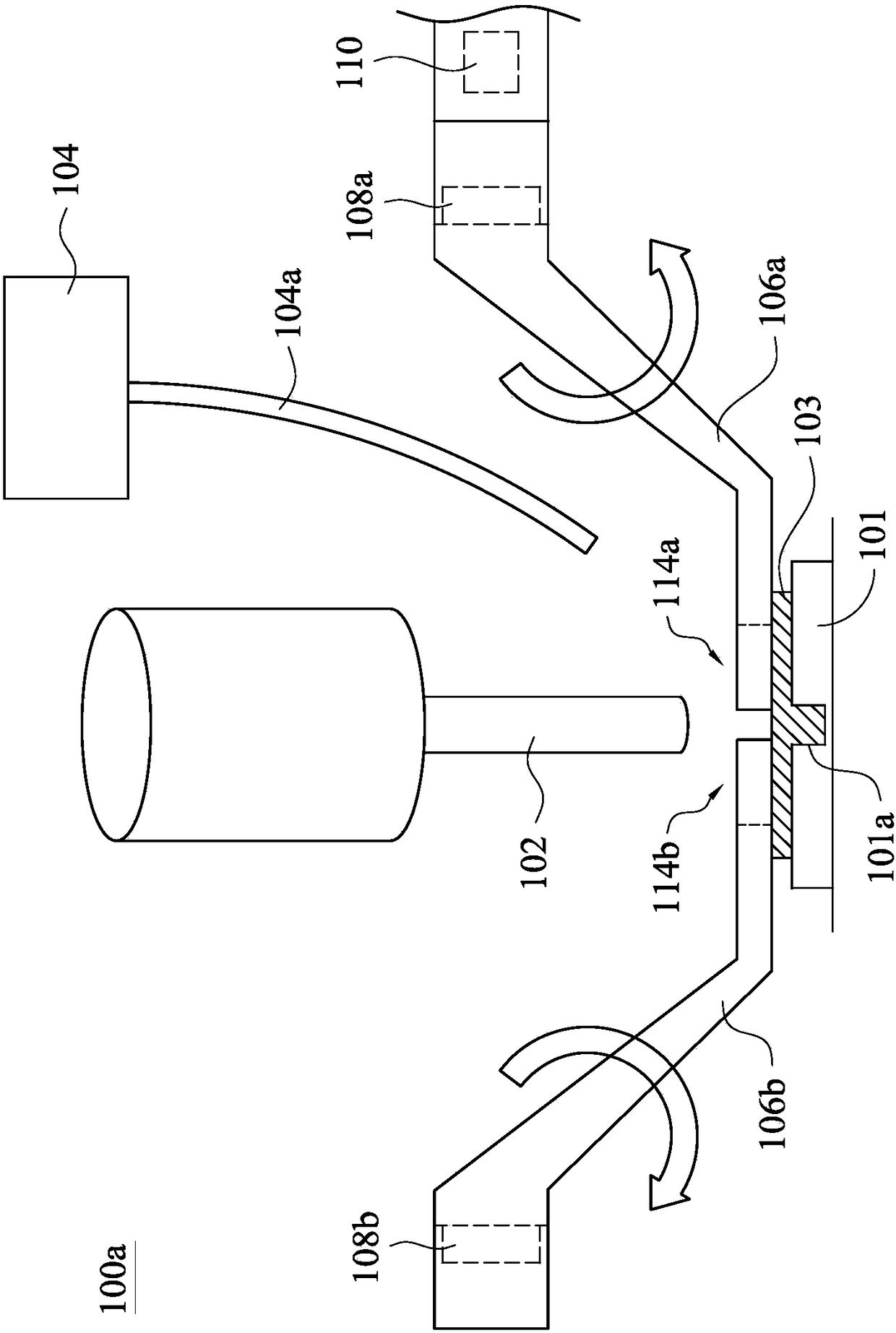

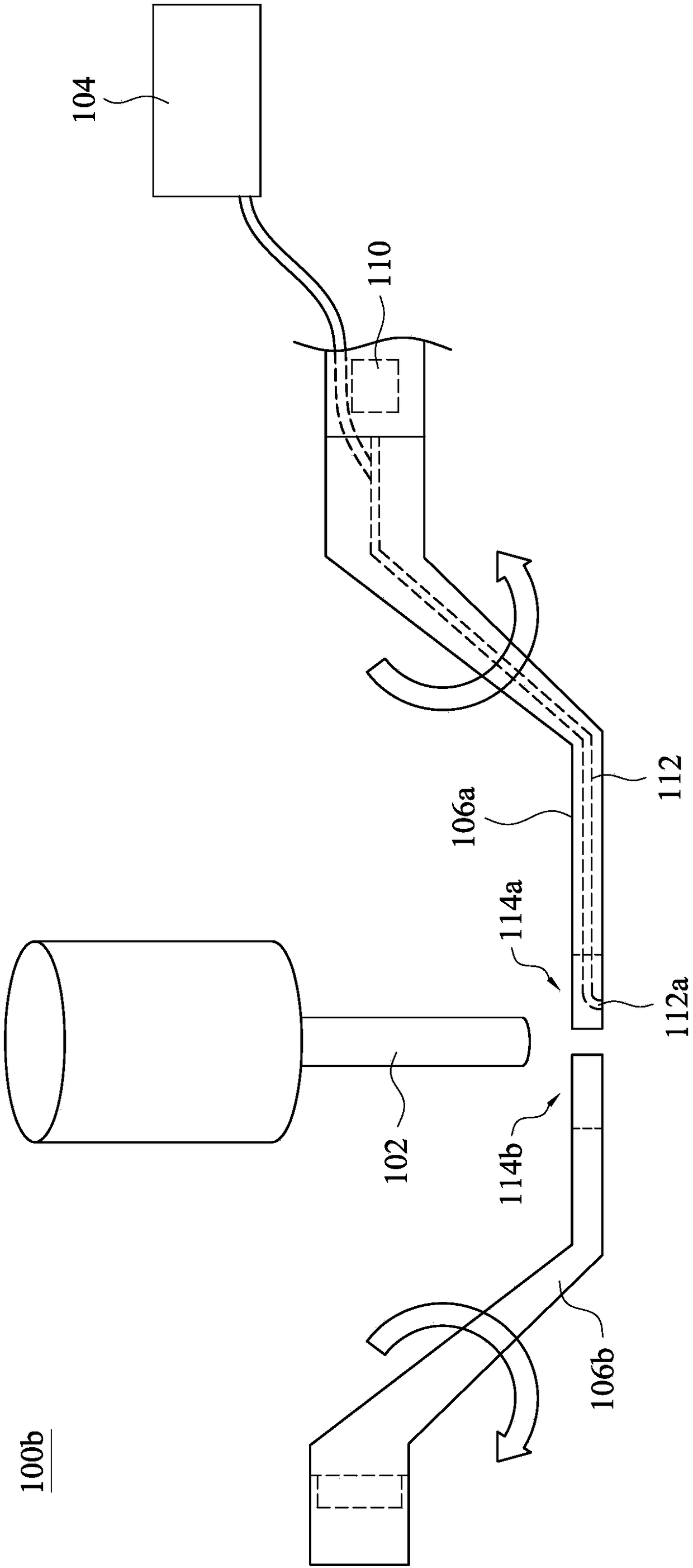

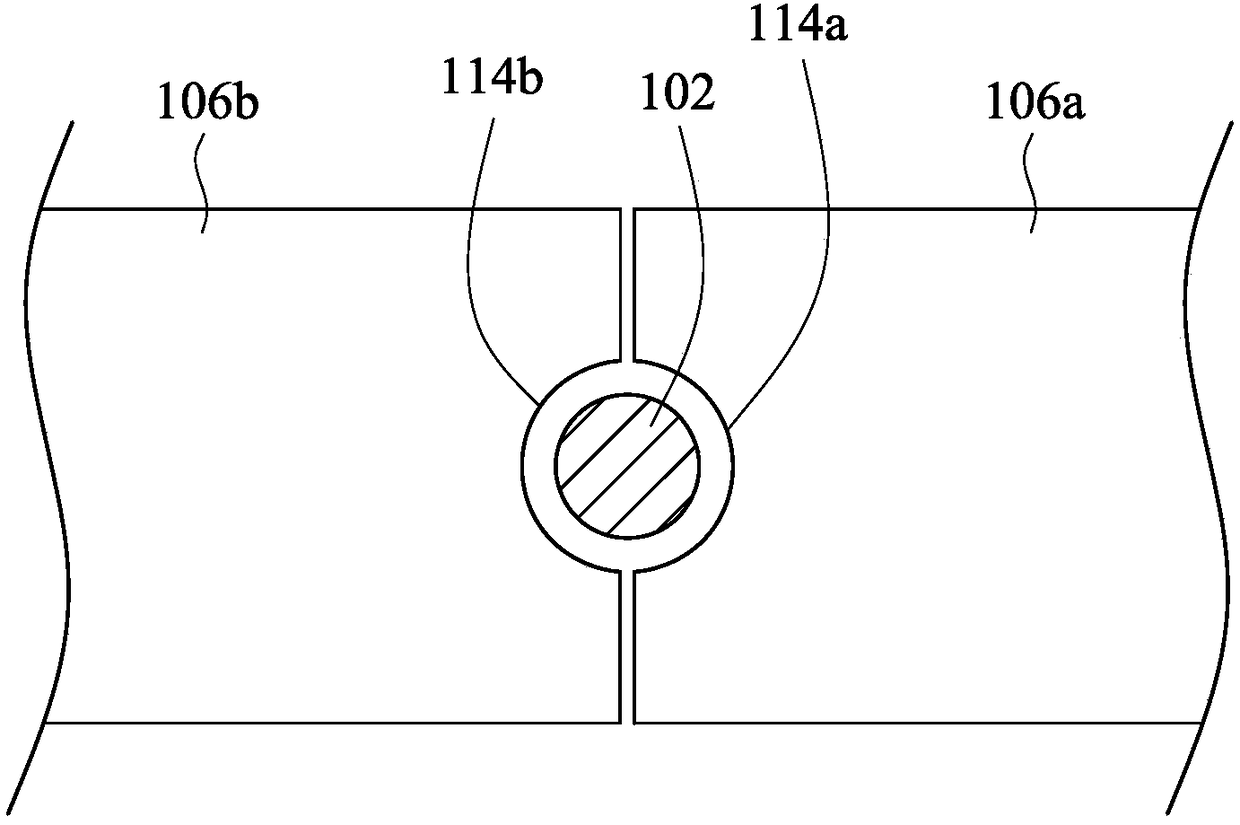

[0027] Please refer to figure 1 , which shows a schematic side view of the ultrasonic assisted processing device according to an embodiment of the present invention. The ultrasonic assisted processing device 100 a includes a processing tool 102 , a first resonant rod 106 a , a second resonant rod 106 b and a liquid supply unit 104 . In this embodiment, the processing tool 102 may be a discharge electrode for electric discharge machining, a drill bit, a milling cutter or other processing tools capable of forming holes 101 a on the surface of the object 101 to be processed. The liquid supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com