Electrical control system for heavy full-hydraulic four-roller plate reeling machine based on PLC

An electric control system and four-roll plate bending machine technology, applied in the mechanical field, can solve the problems of no manufacturer production, etc., and achieve the effect of solving the problem of speed matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings and embodiments.

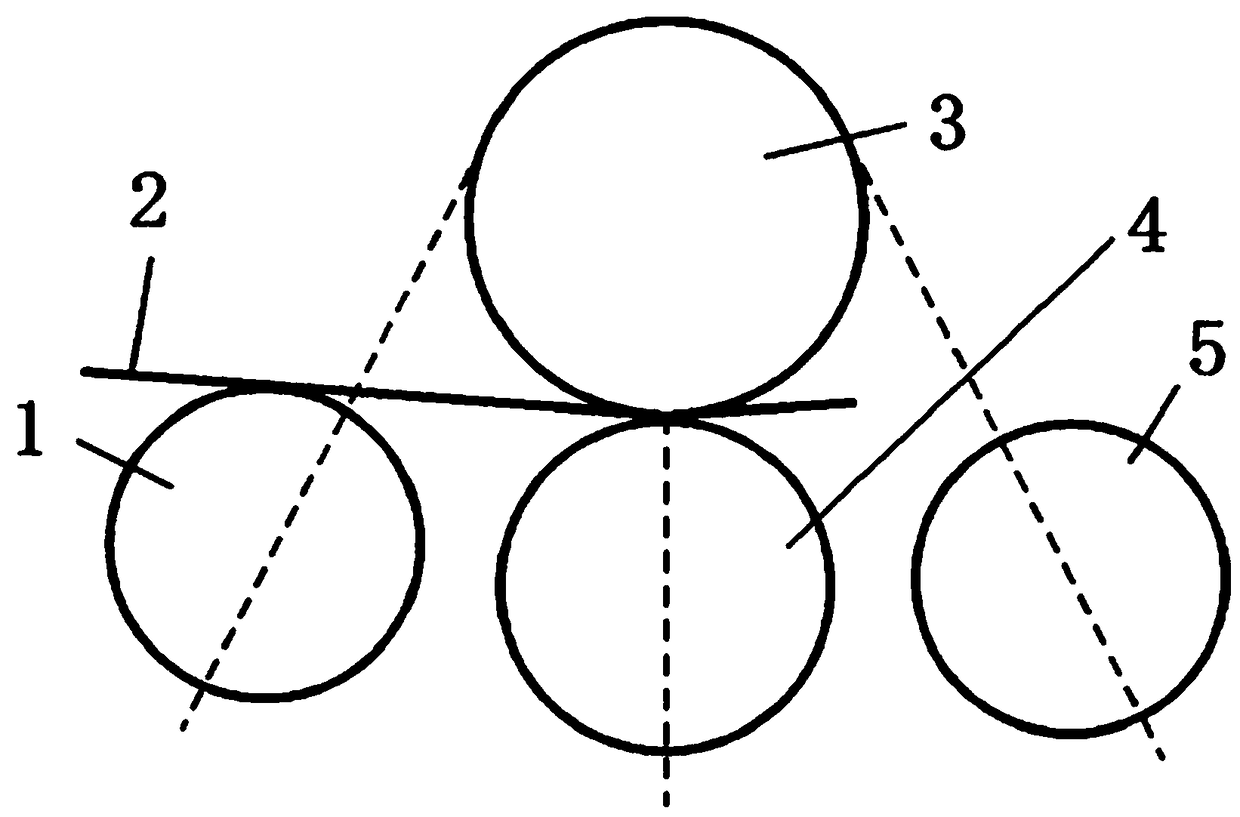

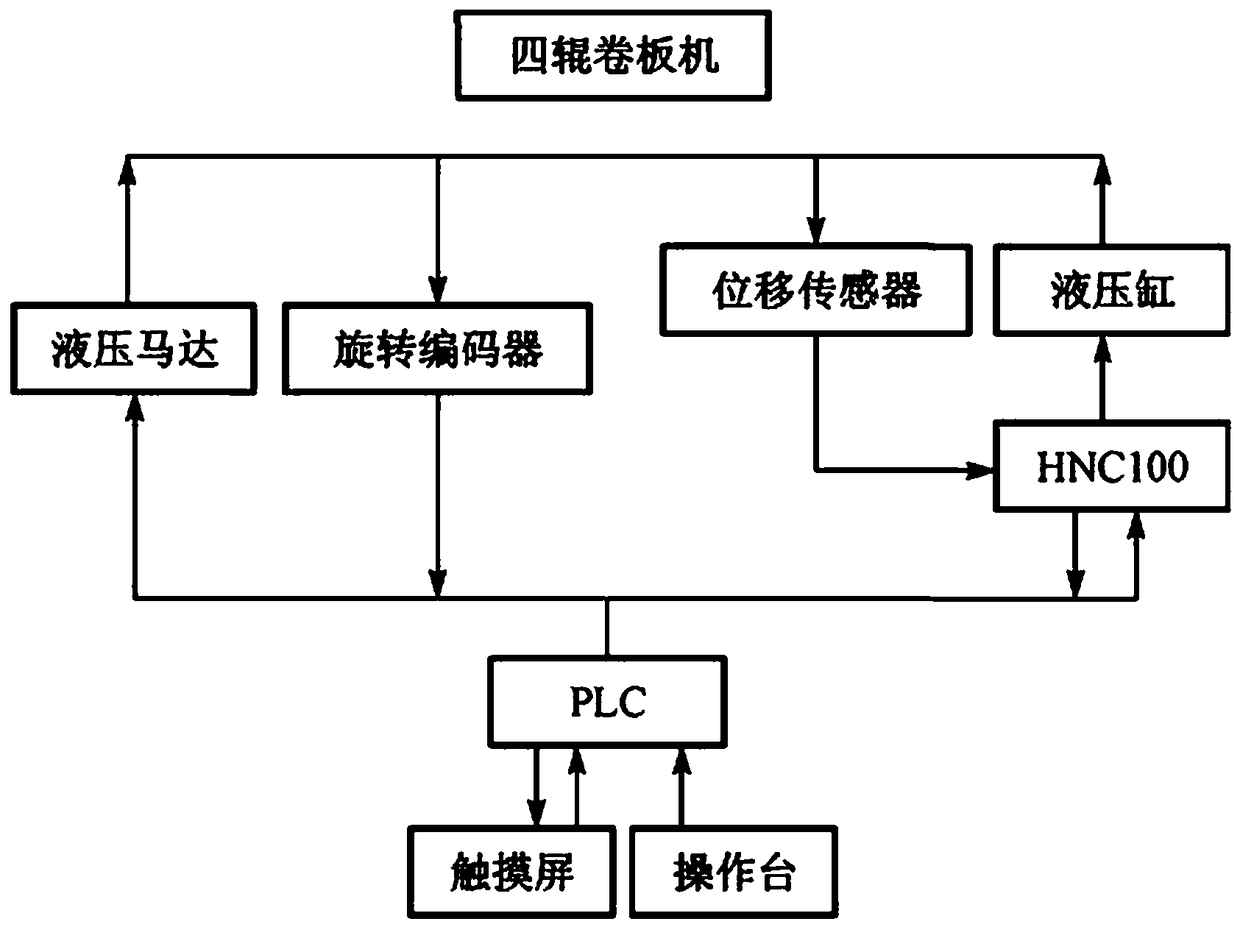

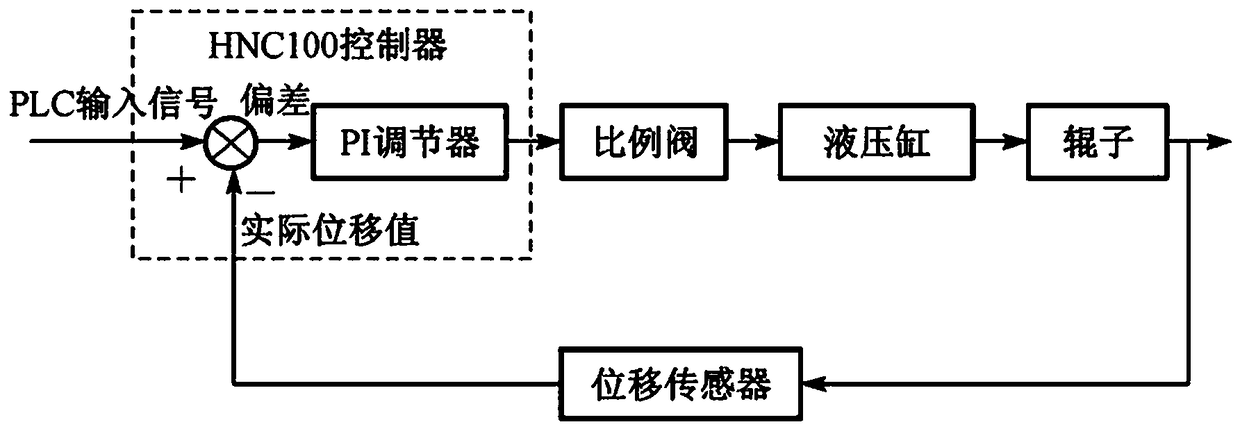

[0015] like figure 1 , The main mechanical components of the four-roller plate rolling machine are upper roller, lower roller, front side roller, rear side roller, hydraulic drive device, reducer and hydraulic motor. The upper roller is fixed between the frames, the lower roller is located at the lower end of the upper roller, and the two side rollers are located on both sides of the lower roller. The lifting movement of the lower roller and the two side rollers is driven by hydraulic cylinders at both ends. The upper and lower rollers are both main rotating drive rollers. The rotation of the upper roller adopts the full hydraulic drive mode of output torque of multiple hydraulic motors and the confluence of the reducer, and the rotation of the lower roller adopts the transmission structure of a single hydraulic motor and reducer.

[0016] In the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com