Assembly for controlling gate, liquid level coordination and gap of single groove flotation machine

A technology for controlling components and flotation machines, which is applied in flotation, solid separation, etc., and can solve problems such as poor operation effect and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

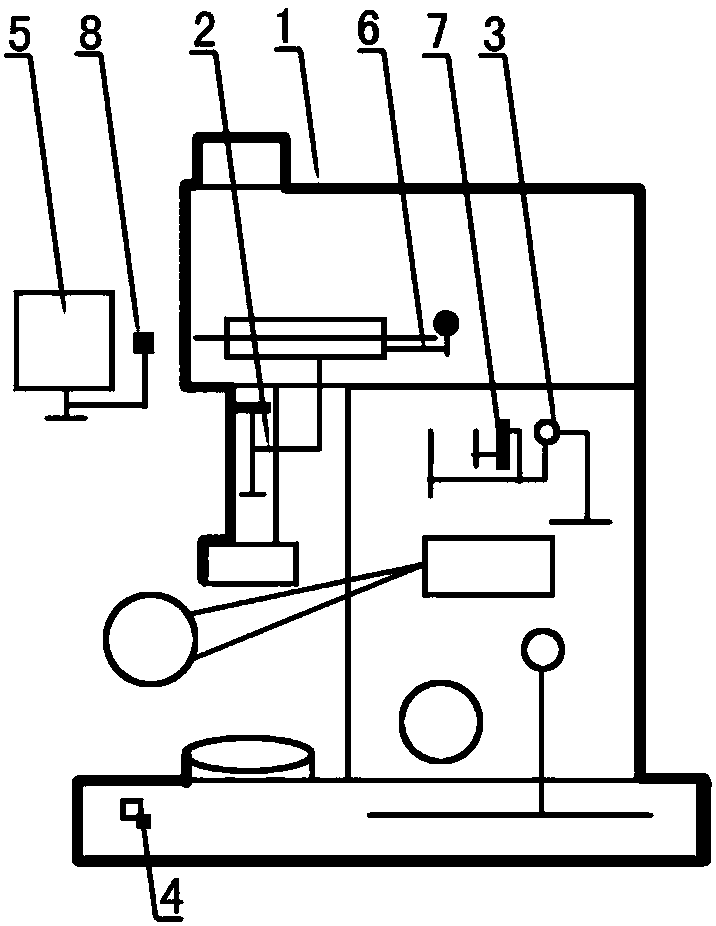

[0012] Embodiment: as shown in the accompanying drawing. Single tank flotation machine gate liquid level coordination gap control assembly, including a body (1), on which is set a precision adjustment module (2), a gap sensing module (3), a remote communication module (4), and a management module (5), during operation, the precision adjustment module (2) is set at the gate adjustment position, the gap sensing module (3) is set between the impeller and the stator, and the remote communication module (4) transmits the sensed information to the management module (5) deal with.

[0013] The gate liquid level coordination gap control component of the single tank flotation machine is provided with a deflection setting module (6) on the precision adjustment module (2), and a reasonable value range of the gate deflection is set according to the liquid level.

[0014] The gate liquid level coordination gap control component of the single tank flotation machine is provided with a conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com