Adjustable transformer high-voltage coil winding mold

A technology of high-voltage coils and transformers, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc. Quality and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

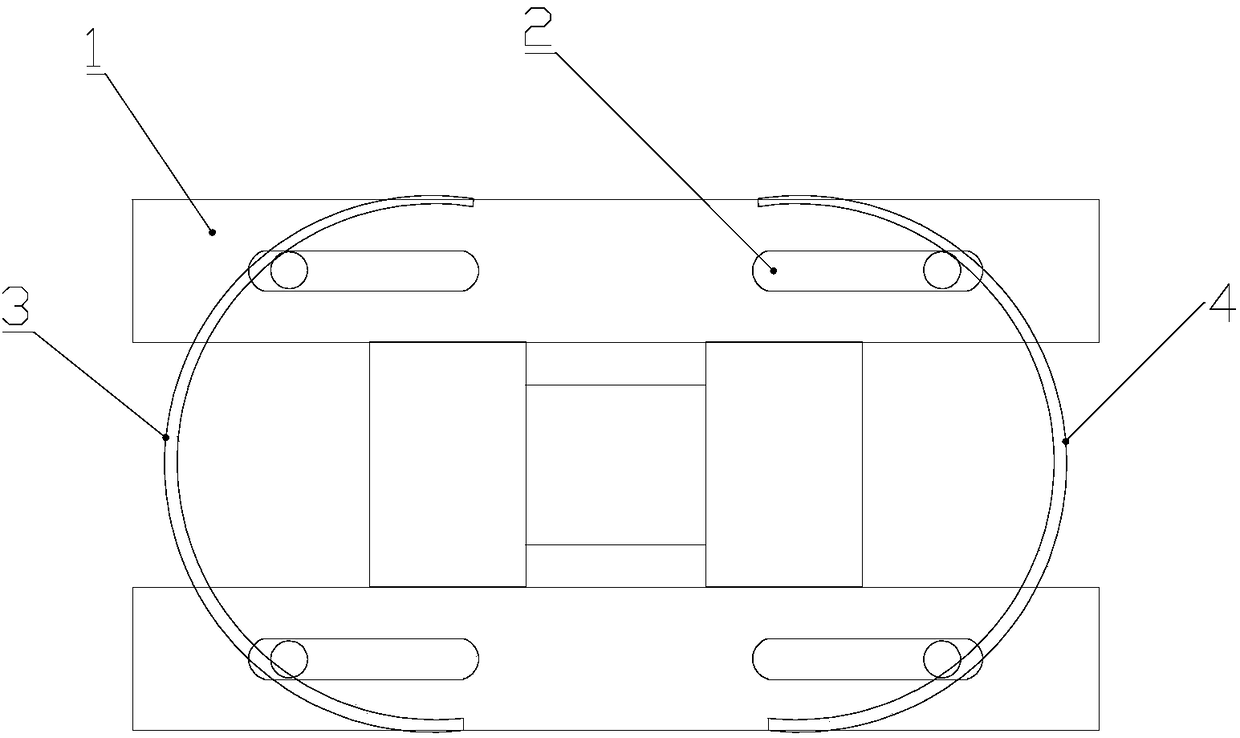

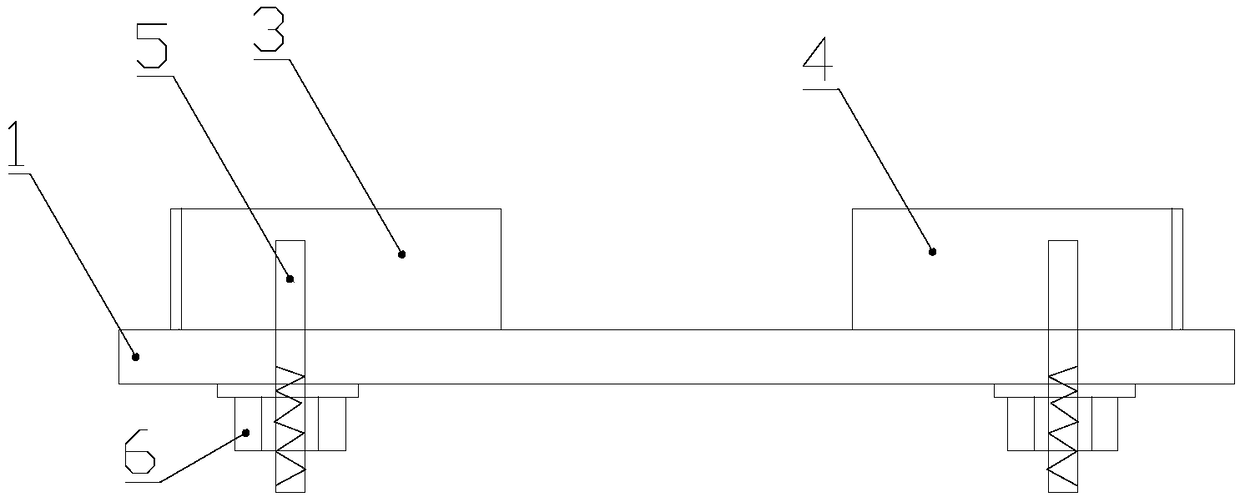

[0015] refer to Figure 1-2 , a transformer high-voltage coil adjustable winding mold provided by the present invention includes a baffle plate 1, four adjustment holes 2 are opened on the baffle plate 1, and a first limit plate 3 and a second limit plate are arranged on the baffle plate 1. Positioning plate 4 and positioning bolt 5 are installed on the adjusting hole position 2, and positioning bolt 5 is welded with the first limiting plate 3 and the second limiting plate 4 respectively, and fastening nut 6 is also arranged on the positioning bolt.

[0016] The baffle plate 1 is made of strip iron, and is arranged in parallel at the bottom; the adjustment hole 2 opened on the baffle plate 1 is in the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com