Method and device for rapidly filtering surface dust in panel detection

A panel inspection and fast filtering technology, applied in the field of image defects, can solve the problems of large differences in dust levels and more consumption, and achieve the effect of optimizing threshold setting, saving man-hours, and enhancing the adaptability of the inspection environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0040] The terms used in the present invention are as follows:

[0041]

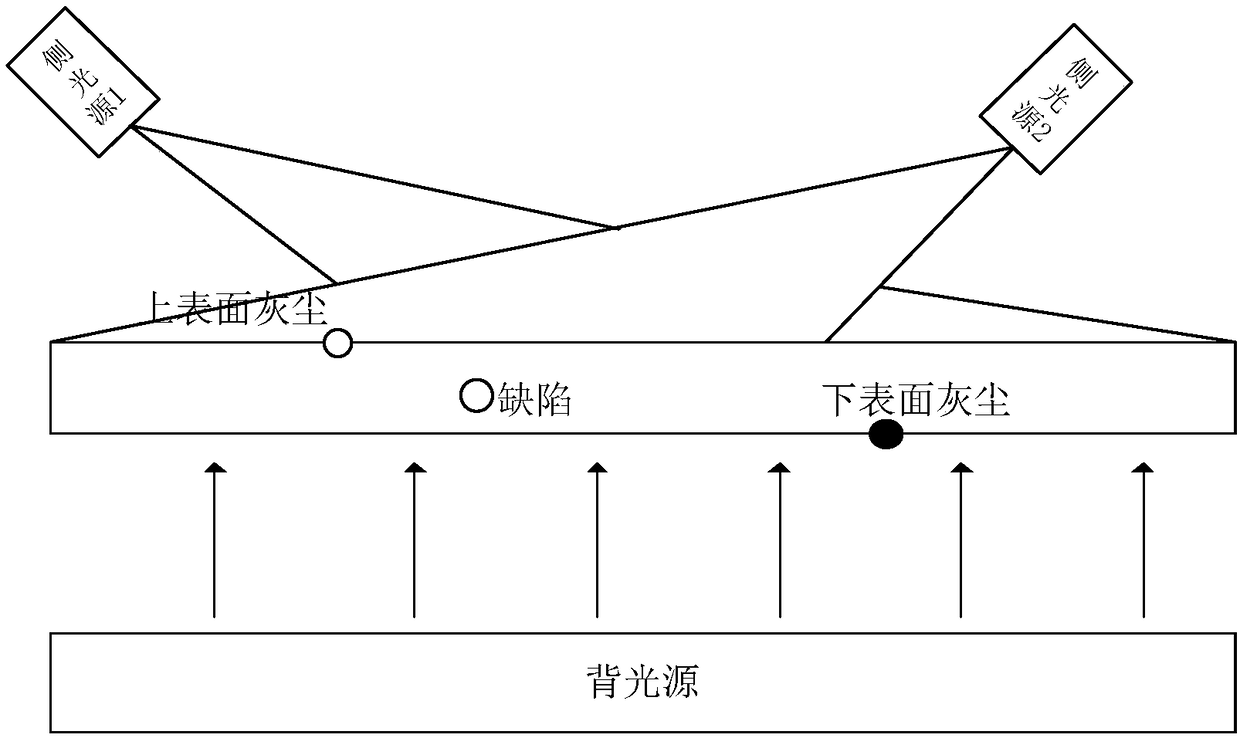

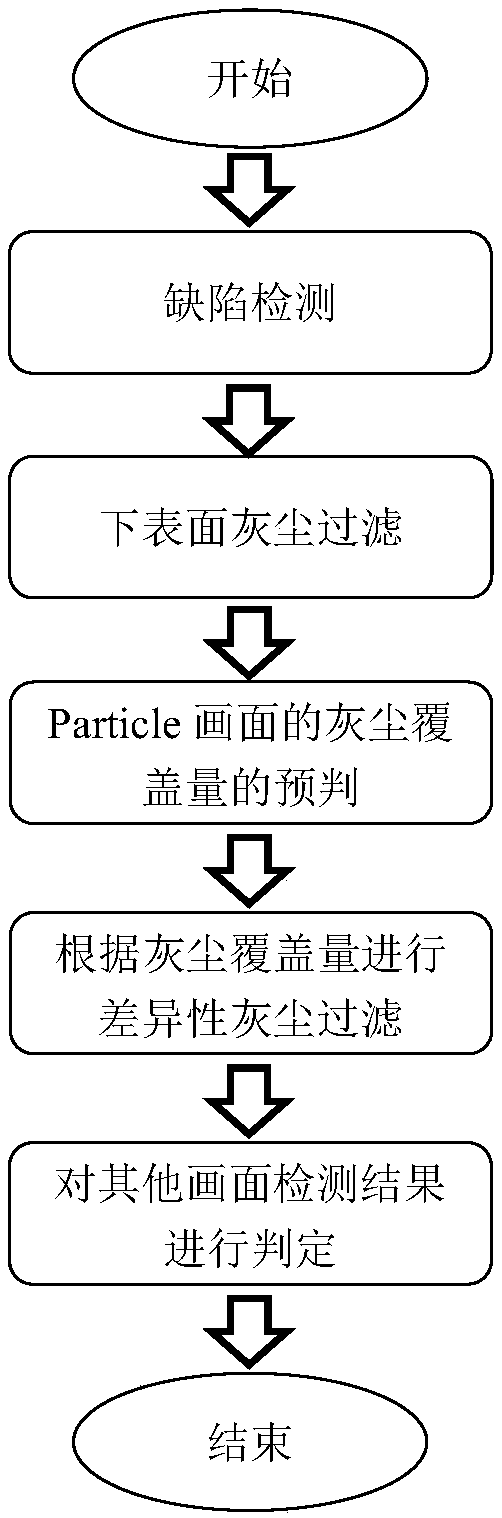

[0042] In the prior art, since the dust on the surface of the LCD panel includes the dust on the upper surface and the dust on the lower surface, two images are usually taken separately, the Particle picture and the ParticleDown picture. figure 2 shown. First, in the ParticleDown screen, take the image of the dust on the lower surface. Since the position of the poor light transmission is generally the position of the lower surface, dark spots are detected in the filtered dust image of the lower surface. The dark spots or dark spots are the dust behind. Side dust is filtered using existing technologies, specifically, it can be filtered using a filtering technology based on defect historical track information. This technology refers to the Chinese patent "A Method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com