Method and symmetrical direct shear apparatus for in-situ testing of pile-soil interface shear strength

A technology of shear strength and in-situ testing, which is applied in the direction of applying stable shear force to test material strength, strength characteristics, instruments, etc., can solve the problem of shear strength measurement of pile-soil interface on site, instrument maintenance and maintenance costs. Expensive, increased manufacturing cost of the direct shearing instrument, etc., to achieve the effect of easy field use, fewer components, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

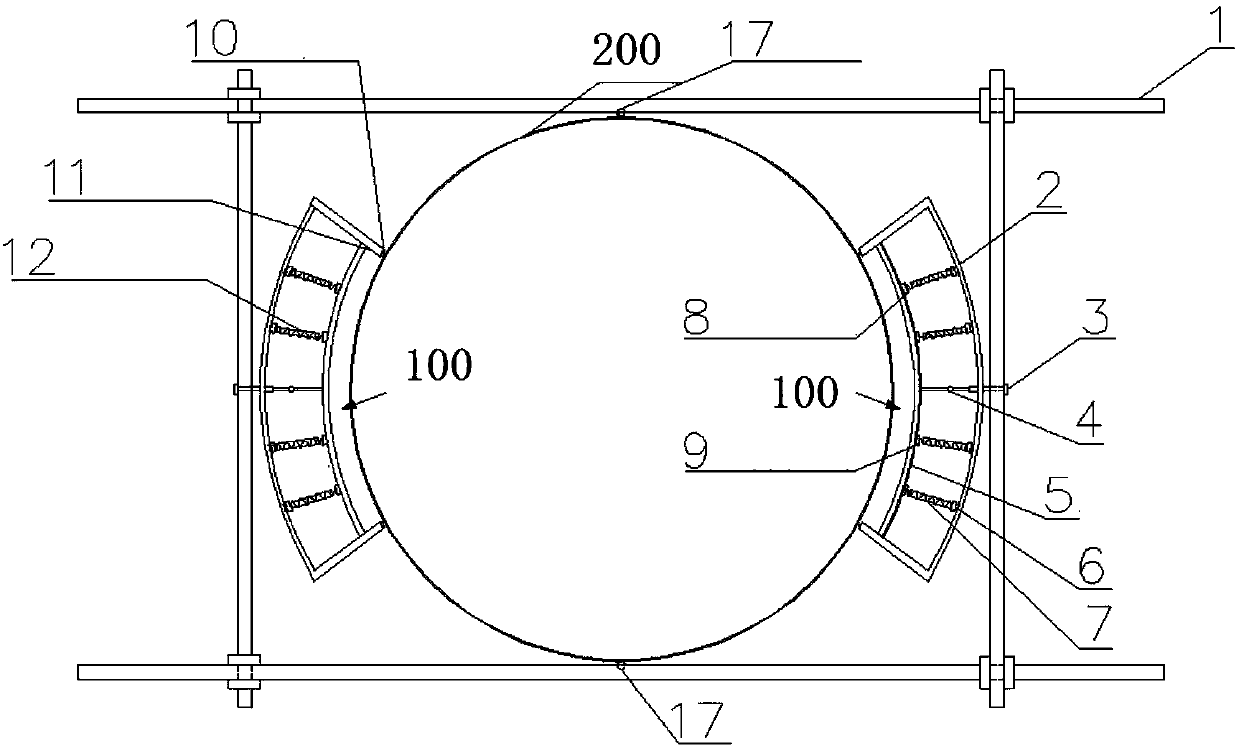

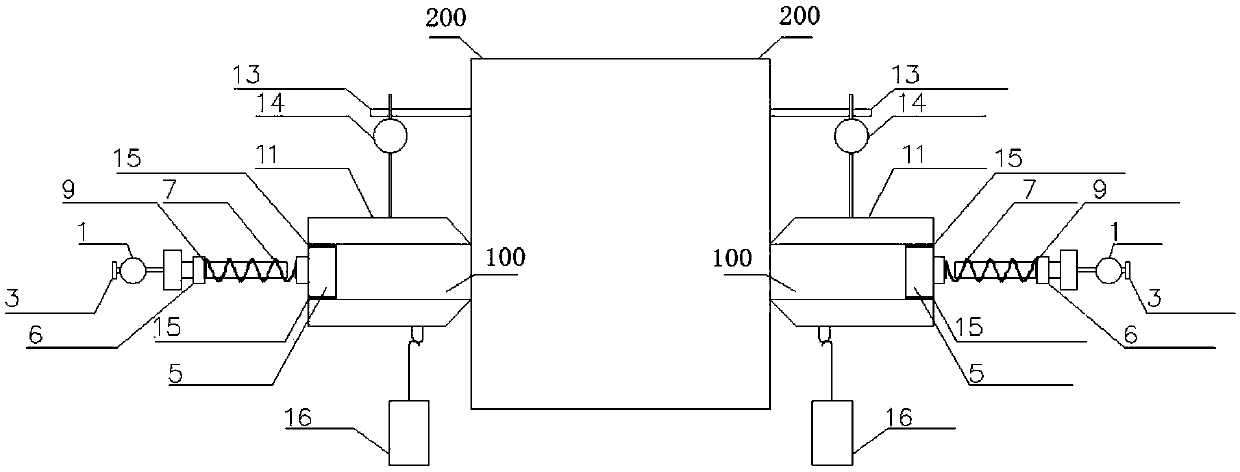

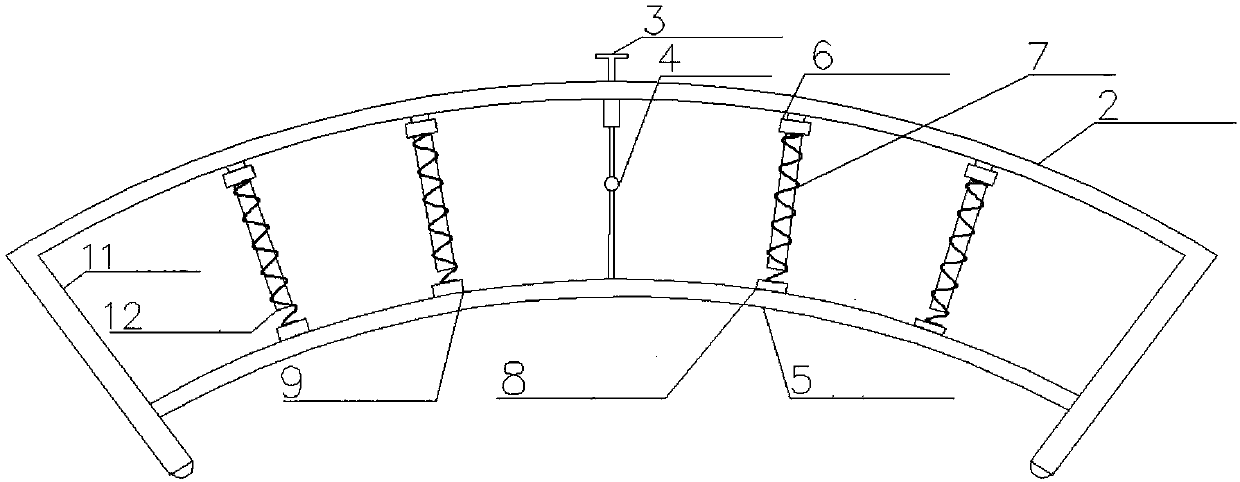

[0033] Such as Figure 1 to Figure 3 As shown, a symmetrical direct shear instrument for in-situ testing of the shear strength of the pile-soil interface includes a support 1, and the support 1 is provided with two symmetrically distributed shearing devices, and the shearing devices include shearing devices. The cutting box 11, the fan-shaped distributed normal force providing mechanism for applying normal force to the soil sample 100 in the shearing box 11, the shear displacement measuring mechanism for measuring the shear displacement of the shearing box 11, and the Shearing box 11 applies the weight 16 of shearing force, wherein, said shearing box 11 is provided with the soil sample placing cavity of placing soil sample 100 and the shearing box upper cover 5 that controls described soil sample placing cavity, The shear box upper cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com