Building window outer level up-suspending hardware system overall performance tester and testing method

A system-integrated, side-opening technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as stiff movements and high failure rates, and achieve smooth control, convenient repair and maintenance, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

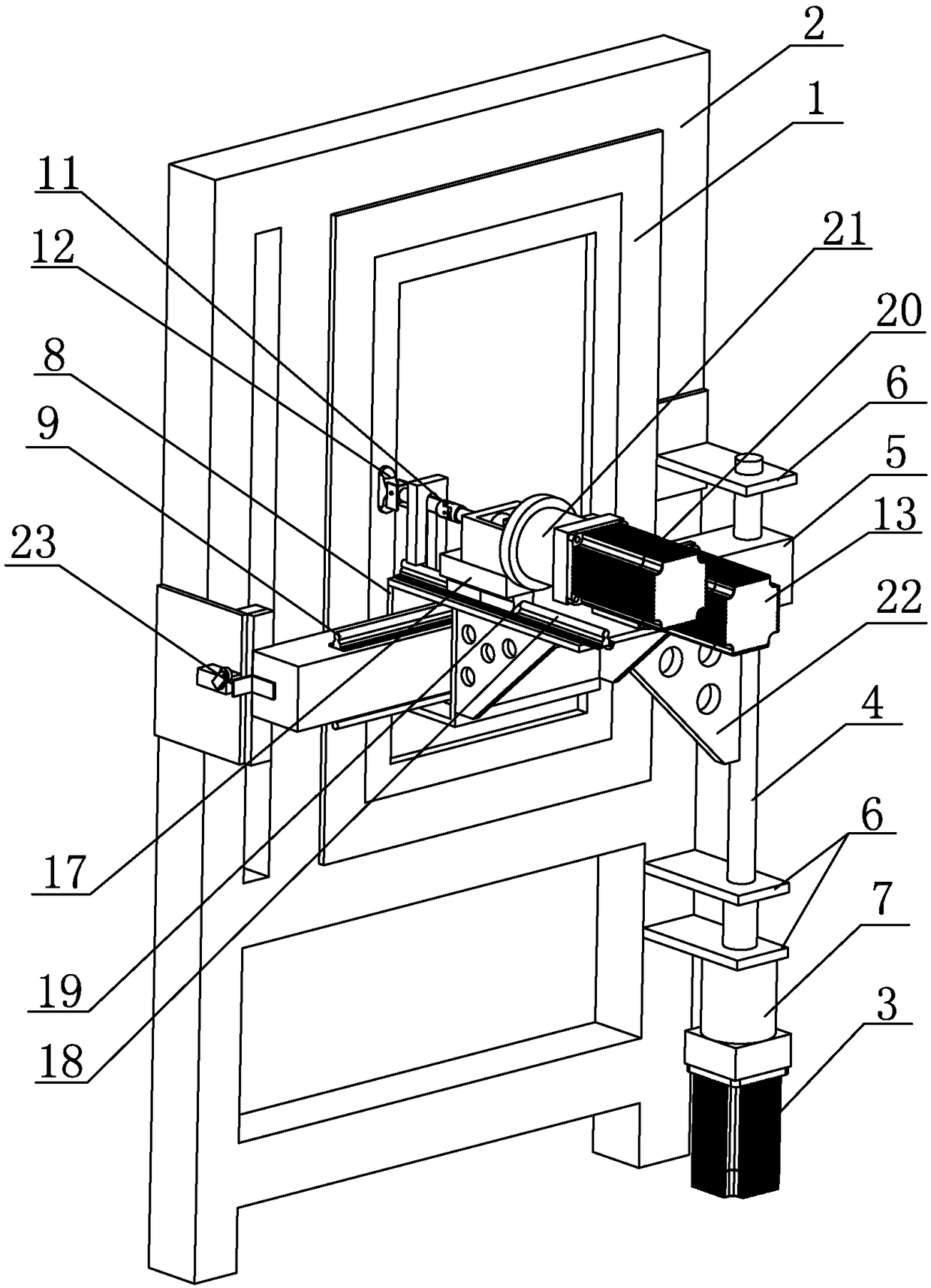

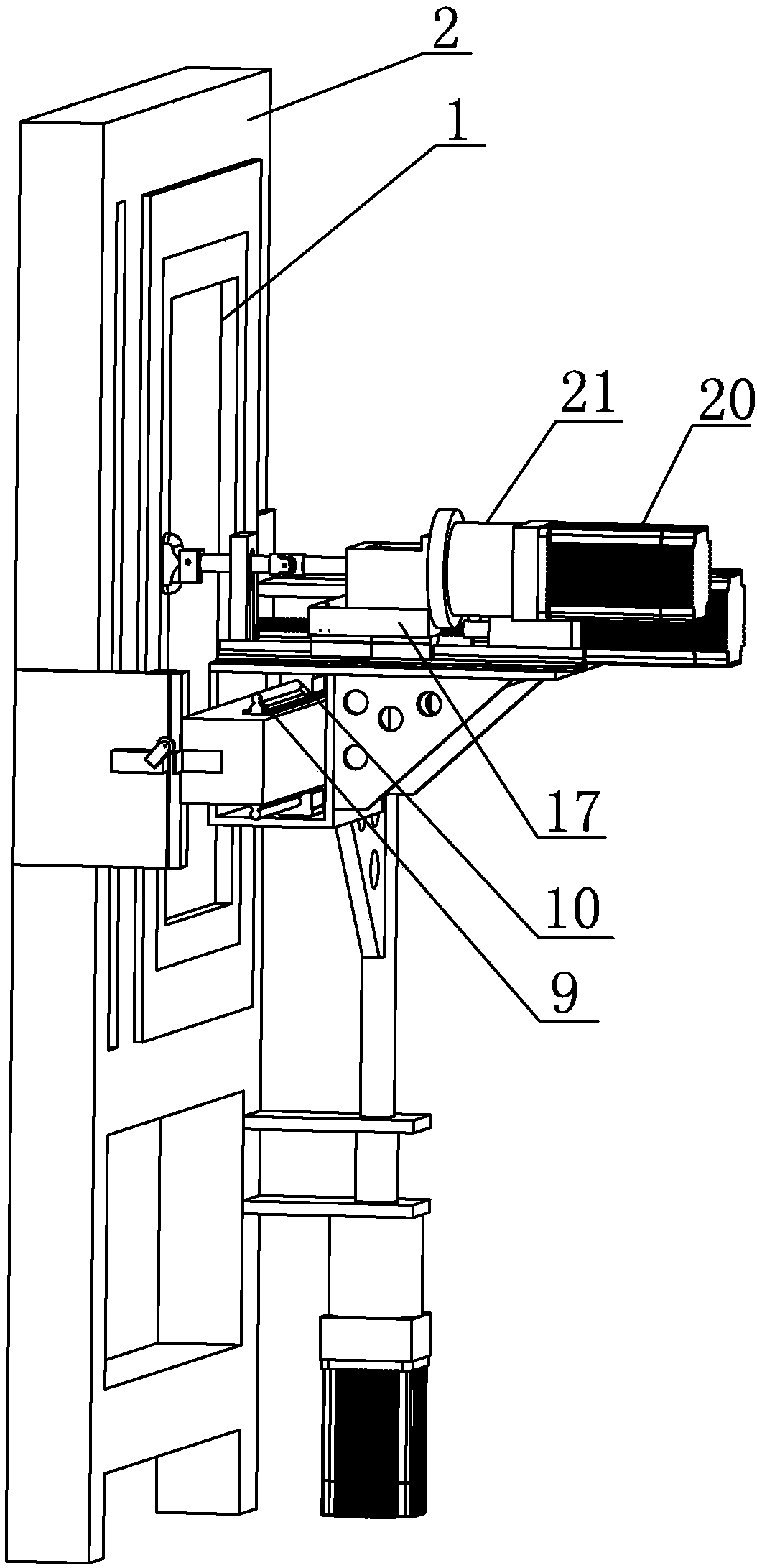

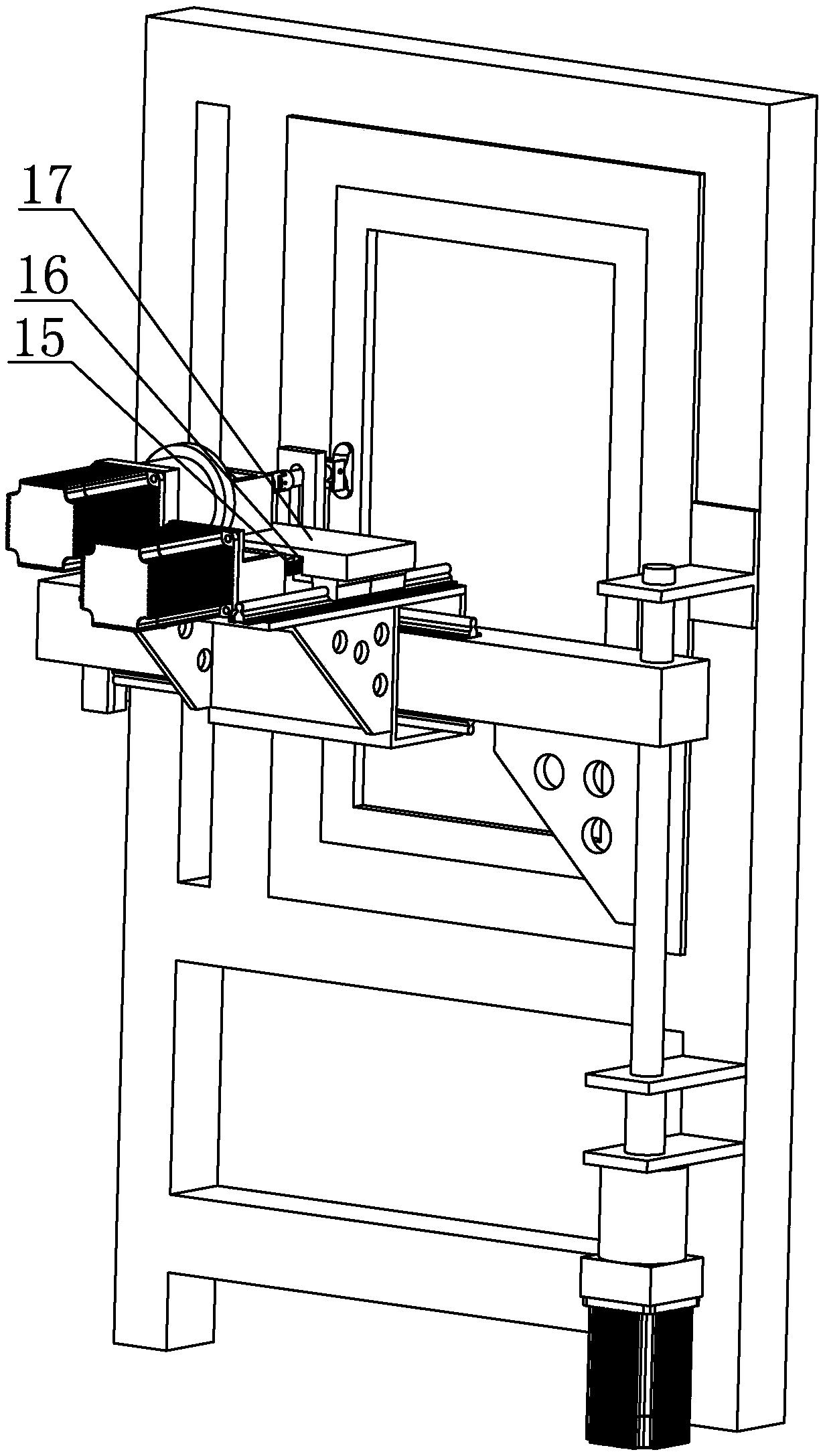

[0027] A comprehensive performance tester for external casement and top suspension hardware systems for building windows, such as figure 1 As shown, it includes a test frame 2 for longitudinally fixing the test simulation window 1, and the outer surface of the test frame 2 is provided with a horizontal opening drive mechanism, an upper suspension drive mechanism and a handle shift mechanism for controlling the handle shift. The opening drive mechanism drives the test simulation window 1 to perform repeated opening and closing movements in the test frame 2 , and the upward suspension drive mechanism drives the test simulation window 1 to perform the upward suspension repeated opening and closing movements in the test frame 2 .

[0028] In this specific example, as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, the swing driving mechanism includes a swing servo motor 3, a longitudinal shaft 4 and a horizontal suspension beam 5, the swing servo motor 3 is ...

specific Embodiment 2

[0031] A kind of method that utilizes the tester described in above-mentioned specific embodiment 1 to test the overall performance of the building window with the outer casement and top suspension hardware system, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown, including the following steps:

[0032] (1) The swing servo motor 3 is turned on, and the swing servo motor 3 drives the horizontal suspension beam 5 to rotate around the longitudinal shaft 4. The horizontal suspension beam 5 drives the driven rod 11 to make an arc-shaped movement through the guide connector 8, and the driven rod 11 Drive the test simulation window 1 to open outwards to the maximum position; then open the servo motor 3 to drive the horizontal suspension beam 5 to reversely rotate around the longitudinal shaft 4, and the horizontal suspension beam 5 drives the driven rod 11 to reverse direction through the guide connector 8 Arc movement, the driven rod 11 drives the test sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com