Cast-in-place pile head processing method and a cast-in-place pile with a fast-dismounting pile head

A processing method and technology for cast-in-place piles, which are applied in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of large damage to steel bars, high cost, low pile head processing efficiency, etc., and achieve fast construction speed, low cost, and construction. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

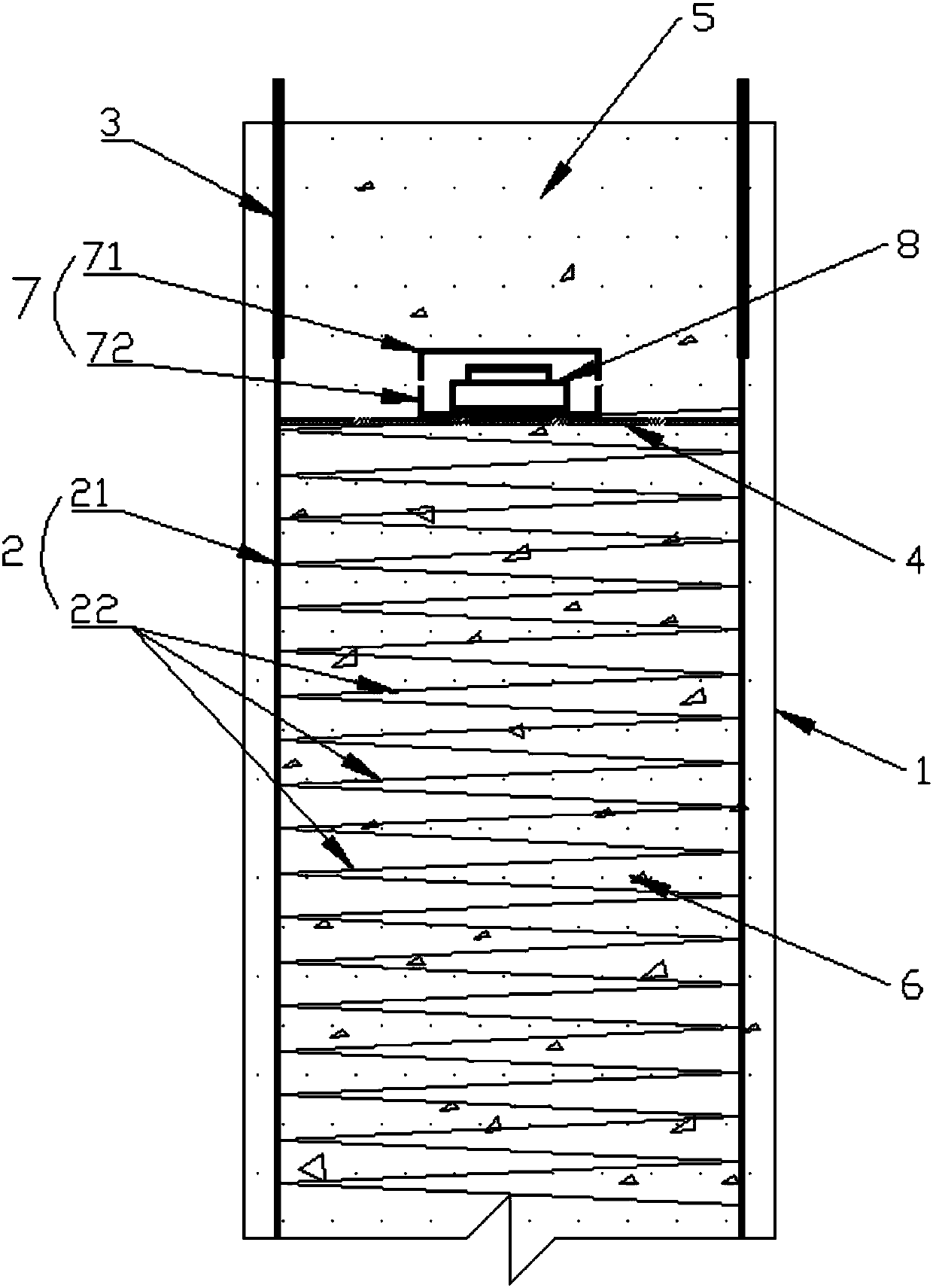

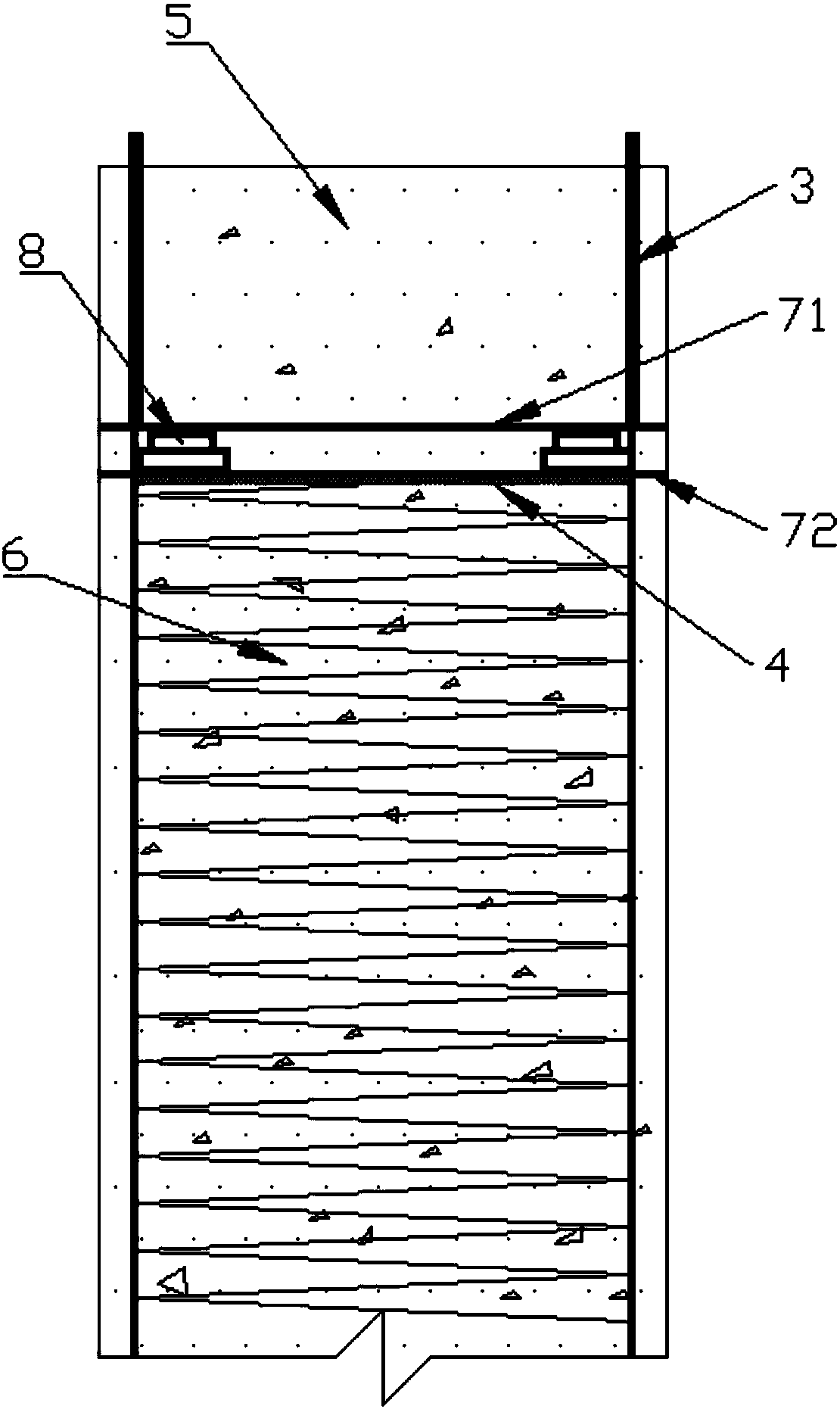

[0030] A method for treating the head of cast-in-place pile, such as Figure 1-3 As shown, the construction steps include:

[0031] ①In the pouring hole 1, set the cast-in-place pile steel skeleton 2 matched with it. The pile body of the steel skeleton 2 includes vertical steel bars 21 and stirrups 22, and the pile head of the steel bar skeleton 2 includes vertical steel bars. twenty one;

[0032] 2. set the steel bar casing 3 on the vertical steel bar 21 of the pile body part, set the vertical steel bar 4 horizontally on the stirrup bar 22 at the top of the pile body part, so that the vertical steel bar 4 is located between the cast-in-place pile head 5 and 6 piles;

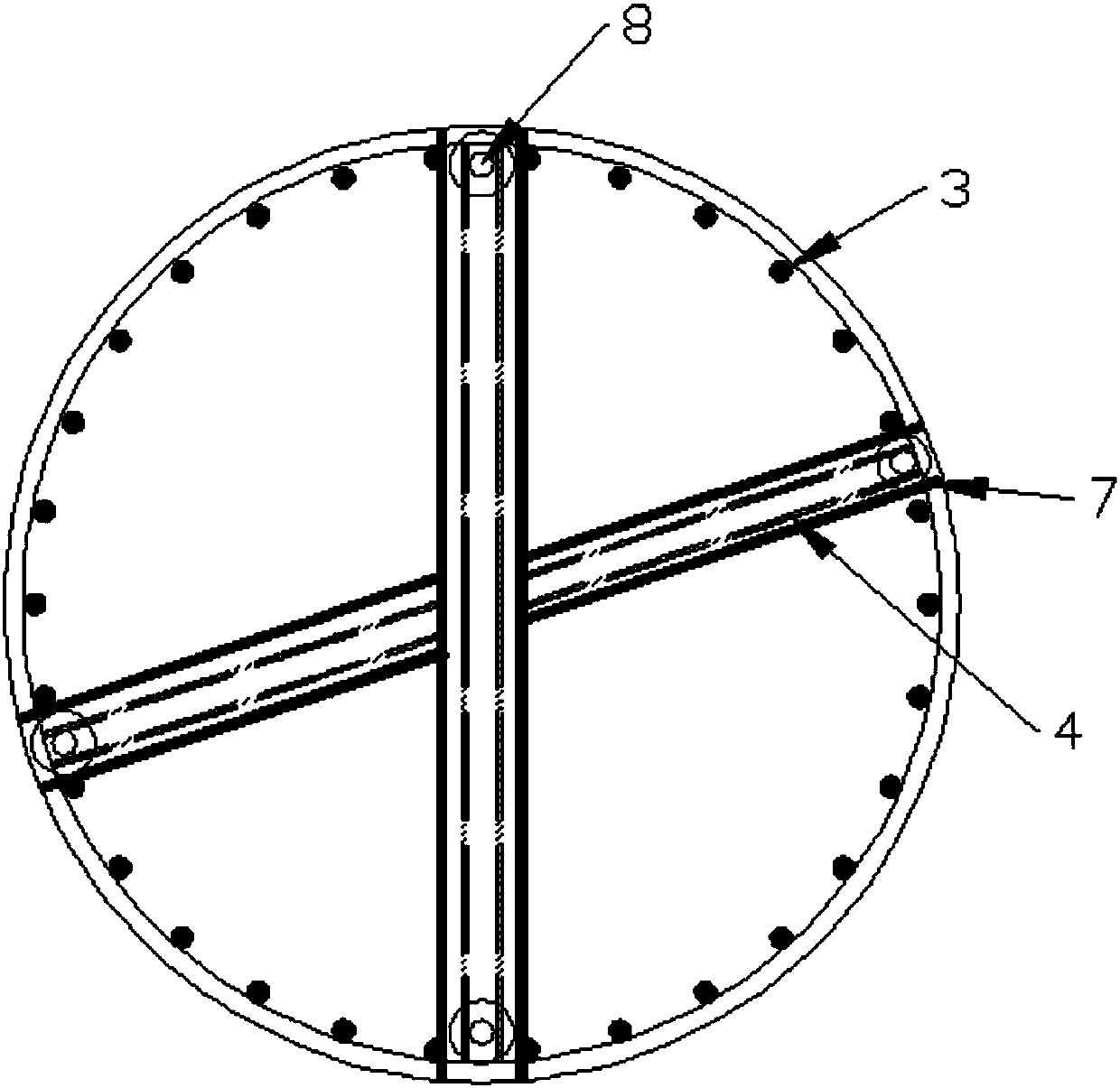

[0033] 3. install the hollow formwork 7 on the erecting steel bar 4, so that the hollow formwork 7 is arranged at the bottom of the pile head 5 above the cast-in-place pile body 6, and the hollow formwork 7 is opposite to the pile body 6 The axis is centrally symmetrical;

[0034] ④ Pour concrete into the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com