Shift fork module

A technology of shift fork shaft and transmission module, which is applied in the direction of mechanical control devices, components with teeth, instruments, etc., can solve the problems of low operability, achieve smooth and accurate operation, simplify shifting operation and selection mode, and improve The effect of assembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

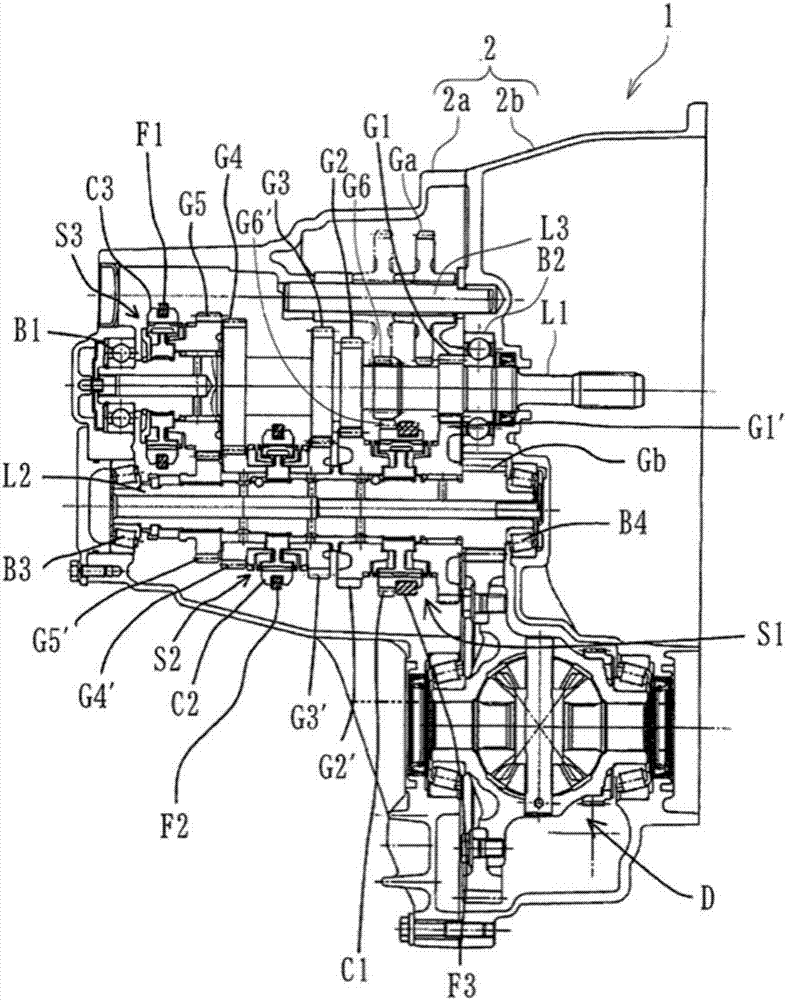

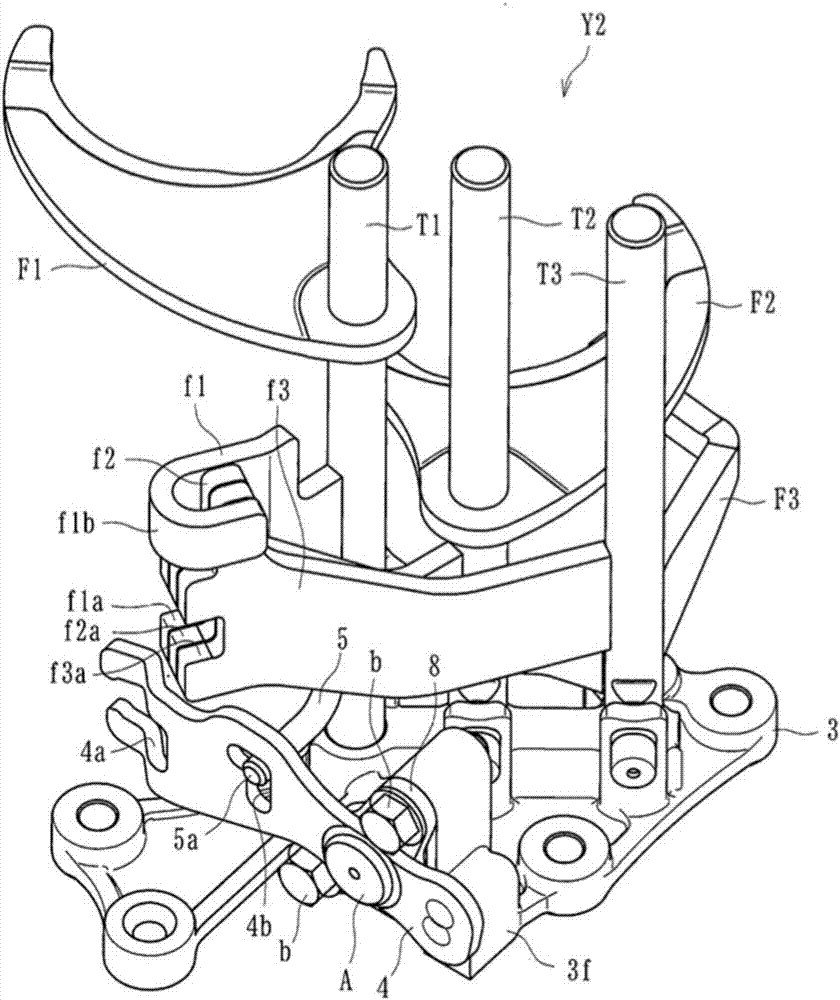

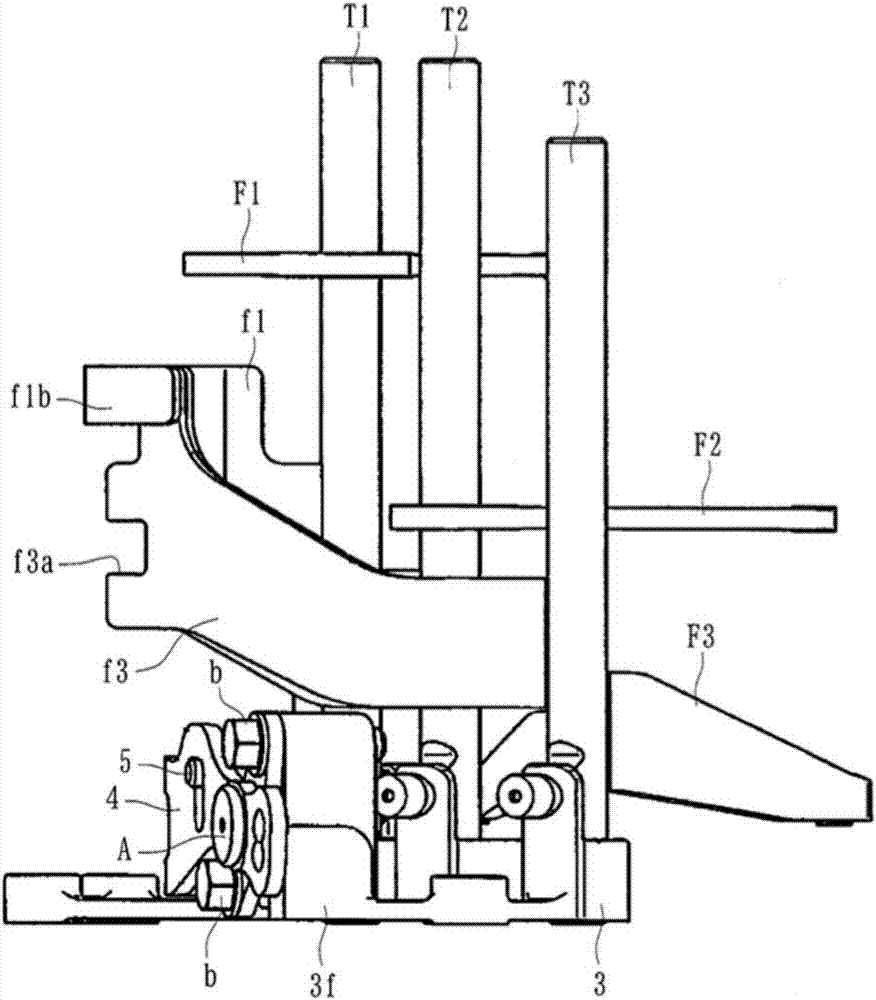

[0053] The power transmission 1 applied in the present embodiment (first and second embodiments) is installed on a vehicle such as an automobile, and obtains an arbitrary shift phase or reverse phase through the driver's operation. Such as Figure 1~4 As shown, the power transmission 1 is based on the fork module Y2 ( figure 2 ) assembled to the transmission module Y1 ( figure 1 ), wherein the input shaft L1 (first shaft), the main shaft L2 (second shaft), and the secondary shaft L3 (third shaft) of the transmission module Y1 are rotatably supported on the housing member 2b, and a plurality of dials The fork shafts T1 - T3 are slidably supported on the bottom member 3 . The power transmission 1 obtained by assembling the fork module Y2 and the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com