Construction method of high-pressure jet-grouted cement soil impervious wall

A technology of high-pressure injection and construction method, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of weak resistance to deformation, thin wall thickness, poor reliability, etc., and achieve cost reduction, investment saving and economic benefits. and huge social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

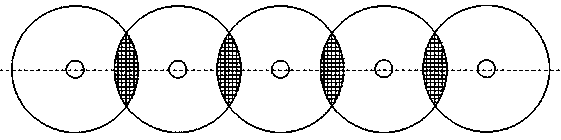

[0044] A certain project is a deep foundation pit support dewatering project, the excavation depth of the foundation pit is 8m, and the design water-stop curtain is 14m. Within the depth range of the water-stop curtain, it is divided into five layers according to lithological characteristics: cultivated soil, silty clay, silt, silty clay, and clay. The soil layer is generally in a soft-plastic state, and the buried depth of the groundwater table is 2m.

[0045] The main construction parameters are designed as follows: Three-pipe construction technology is adopted, water pressure is 25MPa, flow rate is 100L / min; air pressure is 0.7MPa, flow rate is 2m 3 / min; cement slurry pressure 2MPa, flow rate 120L / min; injection pipe 1 lifting speed 16cm / min; the average rotation speed of the variable speed power head 12r.p.m, the angular speed ratio between the maximum and minimum is 1:10, the speed change should be It conforms to the parabolic law.

[0046] Under the conditions of the ...

Embodiment 2

[0048] For a water conservancy cutoff wall project, the dam body is 12m high, and the dam soil is generally cohesive soil; the dam foundation soil is silty clay, sandy soil, small-grained gravel soil, silty clay, and clay. The soil layer is generally in a hard-plastic state, and the depth of the cut-off wall is designed to be 20m.

[0049] The main construction parameters are designed as follows: Three-pipe construction technology is adopted, water pressure is 30MPa, flow rate is 120L / min; air pressure is 0.7MPa, flow rate is 2m 3 / min; cement slurry pressure 2.5MPa, flow rate 150L / min; injection pipe 1 lifting speed 12cm / min; the average rotation speed of the variable speed power head 10r.p.m, the angular speed ratio between the maximum and the minimum is 1:6, the speed change It should conform to the parabolic law.

[0050] Under the conditions of the above construction parameters, the plane shape of a single wall formed in the foundation soil is 1.6m in length and 0.35m in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com