Combined technological method for producing needle coke from coal tar

A technology combining process and process method, applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc., can solve the problems of small thermal expansion coefficient, low impurity content, low ash content of needle coke, etc., to improve the properties of raw materials, fiber Well-structured and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

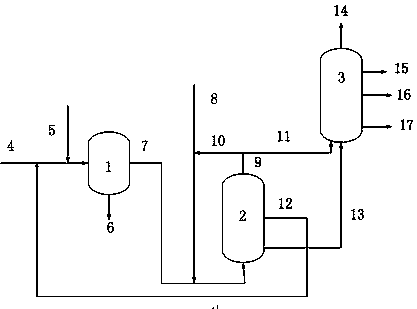

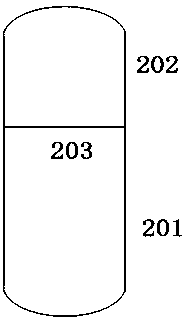

Method used

Image

Examples

Embodiment 1

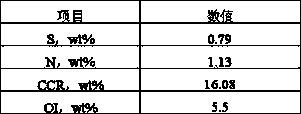

[0034] See Table 1 for the properties of the coal tar used in the test, see Table 2 for the properties of the catalyst filled in the ebullated bed reactor, and circulate the light components generated by the ebullated bed reaction back to the buffer tank with a circulation ratio of 0.2. See Table 3 for the pretreatment conditions. See Table 4 and Table 5 for the reaction conditions of the coking unit. During the coking reaction, the waste hydrogen produced by the ebullating bed reactor is used as the gas used for "coking". See Table 6 and Table 7 for the properties of coal tar raw materials after pretreatment and the properties of needle coke products.

Embodiment 2

[0036] Embodiment 2 has the same raw material properties as in Example 1, and the light components generated by the ebullated bed reaction are circulated back to the buffer tank, and the circulation ratio is 0.4. The pretreatment conditions are shown in Table 3, and the reaction conditions of the ebullated bed reaction device and the coking device are shown in Table 4 and Table 5, the waste hydrogen produced by the ebullated bed reactor is used as the gas used for "coke pulling" during the coking reaction. See Table 6 and Table 7 for the properties of coal tar raw materials after pretreatment and the properties of needle coke products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com