High-performance marine concrete with high water absorption and coarse aggregate and construction method of high-performance marine concrete

A technology of marine concrete and water absorption, which is applied in the processing of building materials, construction, building construction, etc., and can solve the problems of high cementitious material consumption, economic waste, and poor construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Embodiment 1, preparation of large water absorption coarse aggregate high performance marine concrete

[0101] 1 raw material

[0102] Cement and fly ash: CEM II / A-L42.5N cement produced by the rotary kiln of Matola CM Cement Plant in Mozambique and Class I fly ash produced by ULULA in South Africa were used in the test. The quality test results are listed in Table 1 and Table 2, respectively.

[0103] Table 1 Analysis of chemical composition and physical and mechanical properties of cement

[0104]

[0105] Table 2 Physical and mechanical properties of fly ash

[0106]

[0107] Aggregate: The fine aggregate is the natural river sand of the Moamba River in Mozambique. The basic properties and screening results of the sand are listed in Table 3 and Table 4, respectively.

[0108] Table 3 Basic properties of river sand

[0109]

[0110] Table 4 Screening results of river sand

[0111]

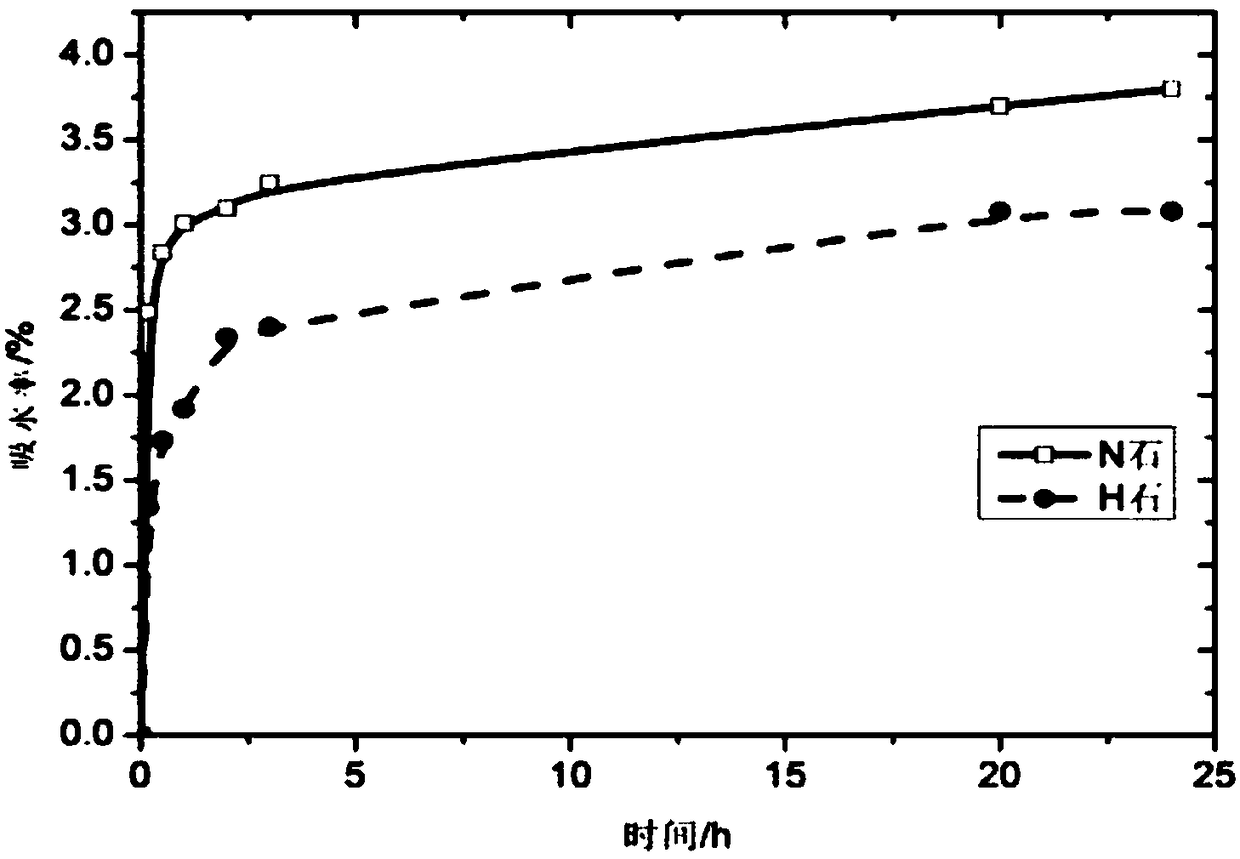

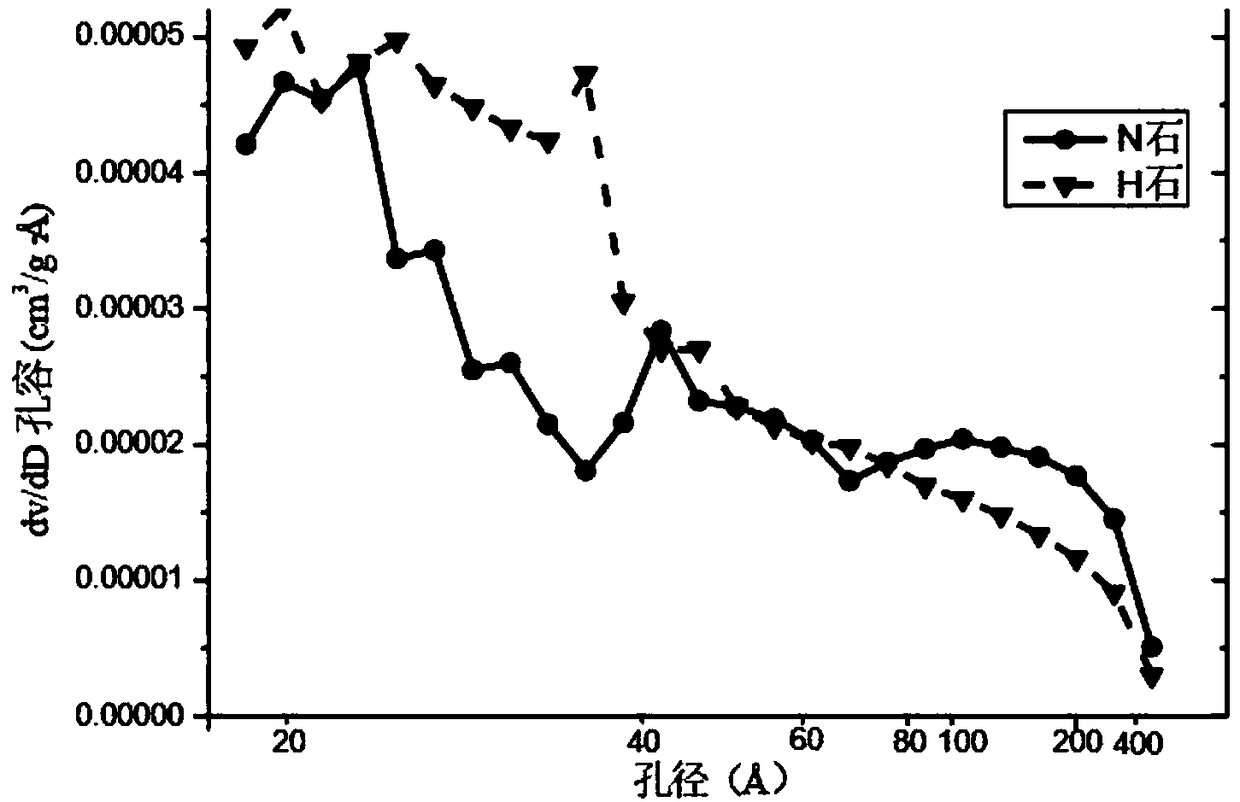

[0112] Coarse aggregates are produced at the Namaacha quarry and Hiper...

Embodiment 2

[0153] Embodiment 2. Construction method of high-performance concrete with large water absorption coarse aggregate

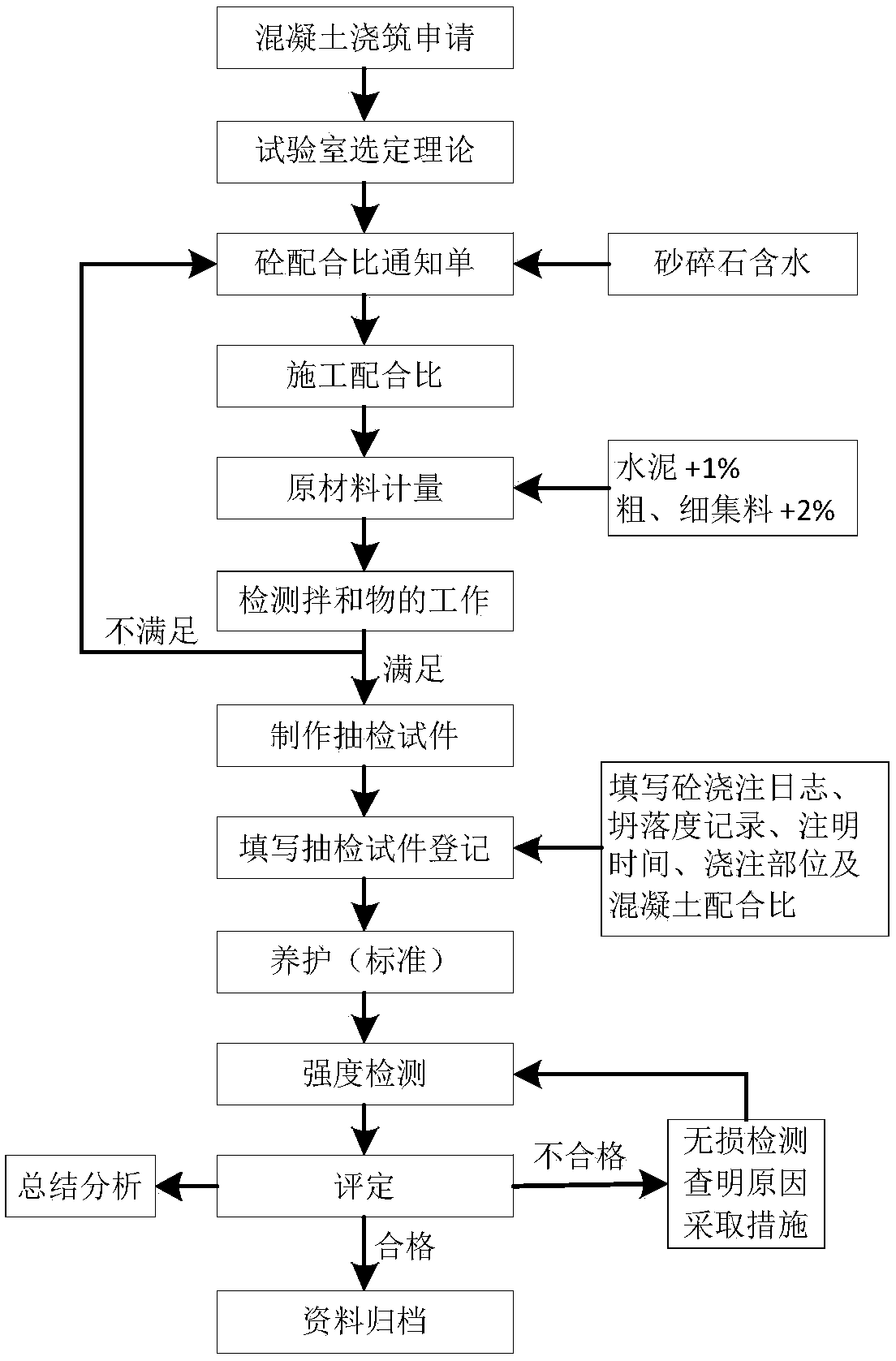

[0154] 1.1 Construction process

[0155] The construction process of high water absorption macadam high performance concrete see image 3 .

[0156] 1.2 Operation points

[0157] At present, the preparation of fair-faced concrete admixtures at home and abroad usually adopts the scheme of "elimination first and then introduction", and polycarboxylate superplasticizers, defoamers and air-entraining agents are often used for preparation, but the water-reducing rate of ordinary polycarboxylate superplasticizers High air content is also high. In order to meet the requirements of reducing the low air content of concrete, more defoamers need to be added. If the amount of defoamers is too high, the concrete will have no "ball" effect, poor fluidity, poor wrapping, and difficult to construct. In order to improve the working performance of concrete, a certain amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com