Biogas slurry waste water treatment system and treatment method thereof

A biogas slurry wastewater and treatment system technology, applied in the chemical industry, can solve the problems of high operating costs, complex methods, difficult management, etc., and achieve the effects of low operating costs and simple treatment systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

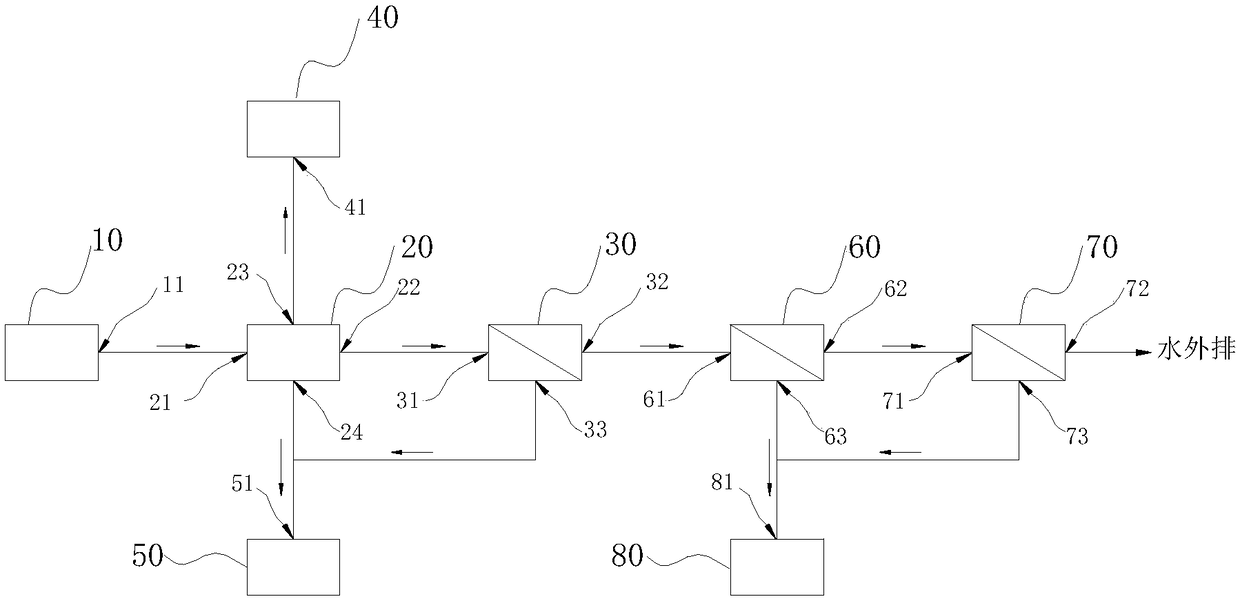

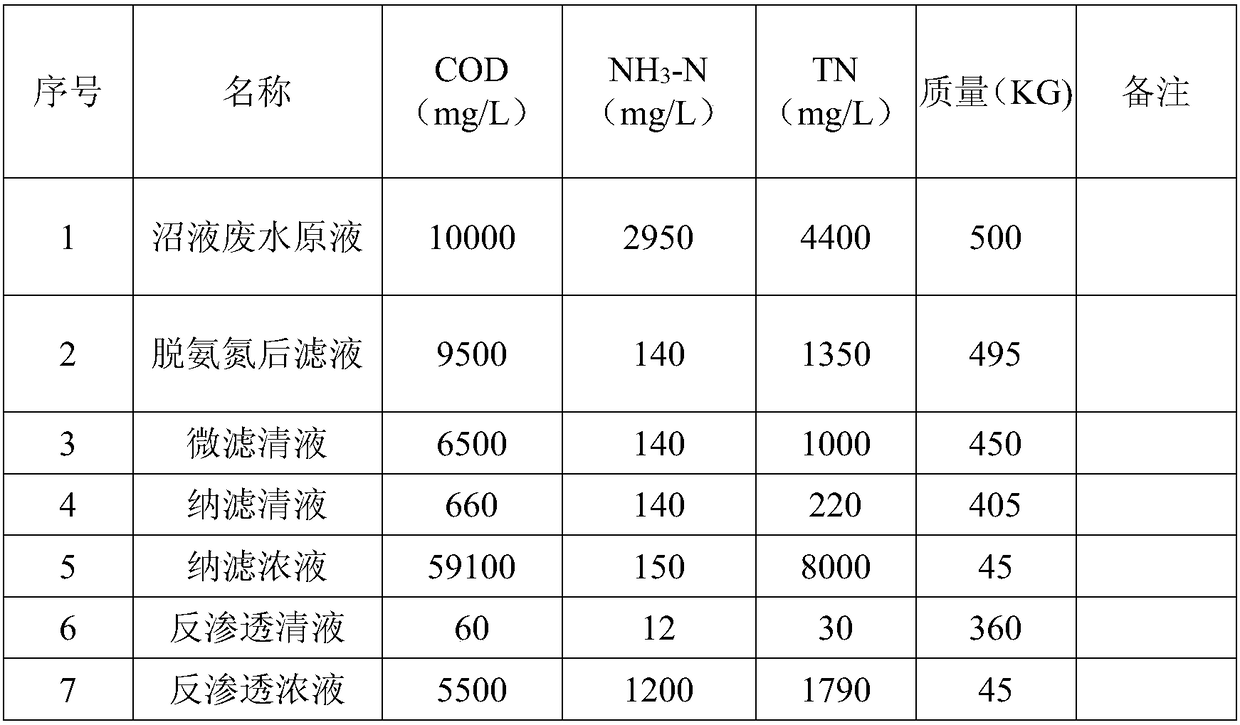

[0014] A biogas slurry wastewater treatment system, such as figure 1 As shown, it includes a storage unit 10 , a nitrogen removal unit 20 , and a filter unit arranged in sequence. The waste water inlet 21 and the filtrate outlet 22 of the nitrogen removal unit 20 are respectively connected to the outlet 11 of the storage unit 10 and the inlet of the filter unit. When in use, pass the biogas slurry wastewater formed by the livestock and poultry manure in the prior art through a plate-and-frame press filter, anaerobic fermentation and a second plate-and-frame press treatment from the storage unit 10 into the deammonization nitrogen unit 20, Under the action of gravity, the thick slag and the clear liquid are layered, and the pH of the waste water in the deammonization nitrogen unit 20 is adjusted to 9-12, so that calcium and magnesium ions are precipitated, wherein the clear liquid is heated and blown off to separate the ammonia water and the filtrate; part of the ammonia nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com