Large-size glass packaging method

A packaging method and glass technology, applied in packaging, transportation and packaging, packaging of fragile items, etc., can solve the problems of unstable glass fixation, unsatisfactory packaging effect, and high packaging cost, and achieve good glass, increased contact area, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] A packaging method for large glass mainly comprises the following steps:

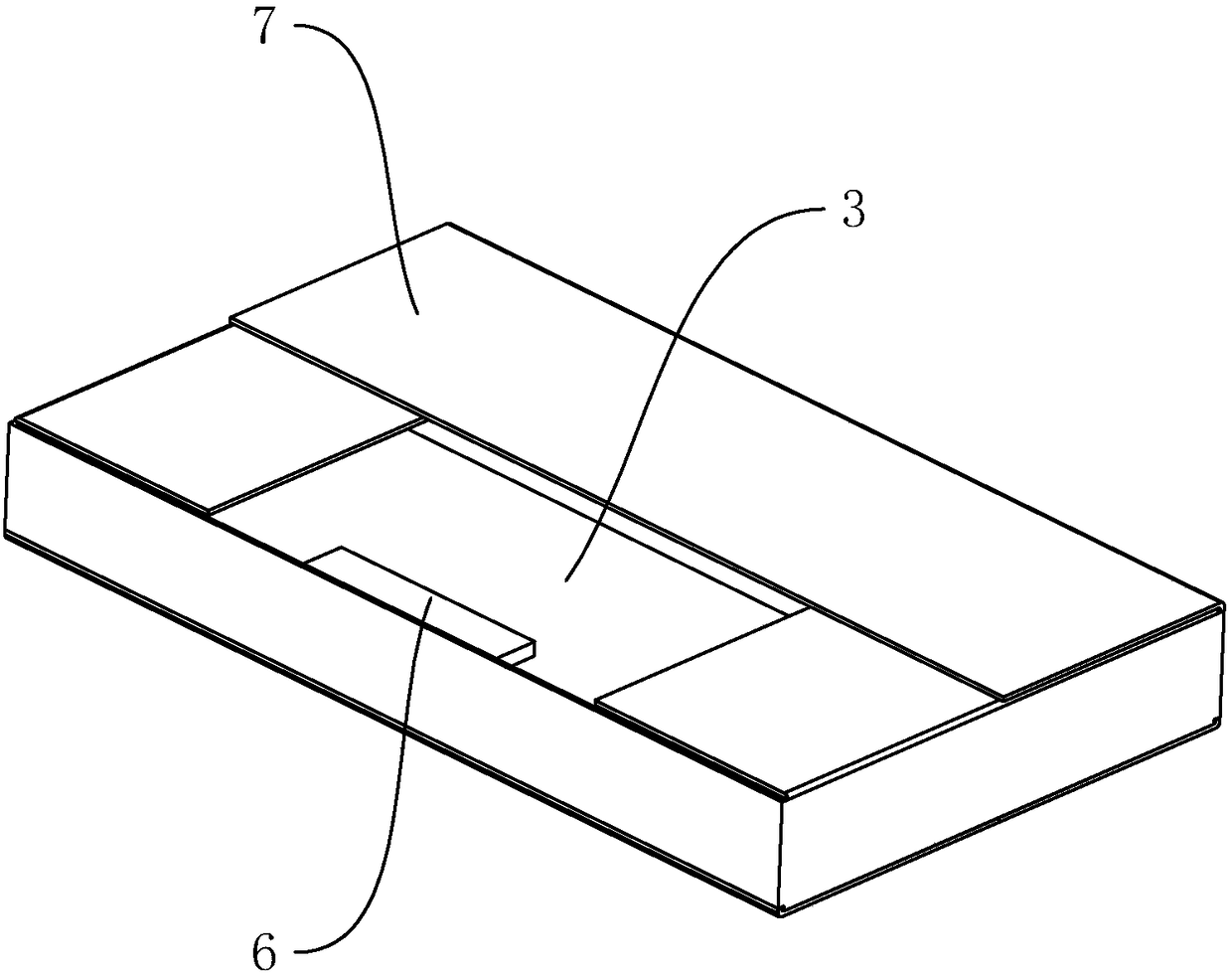

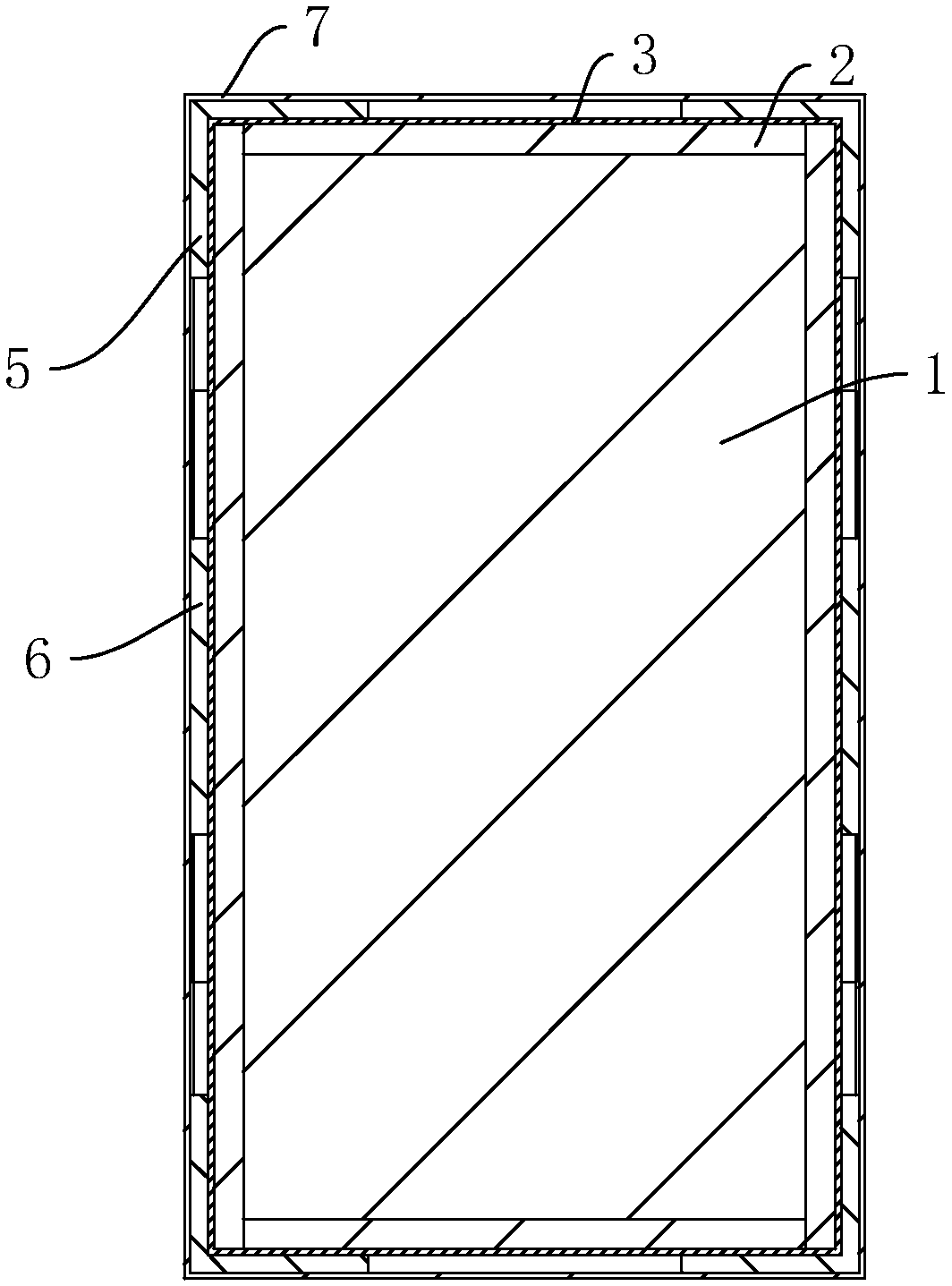

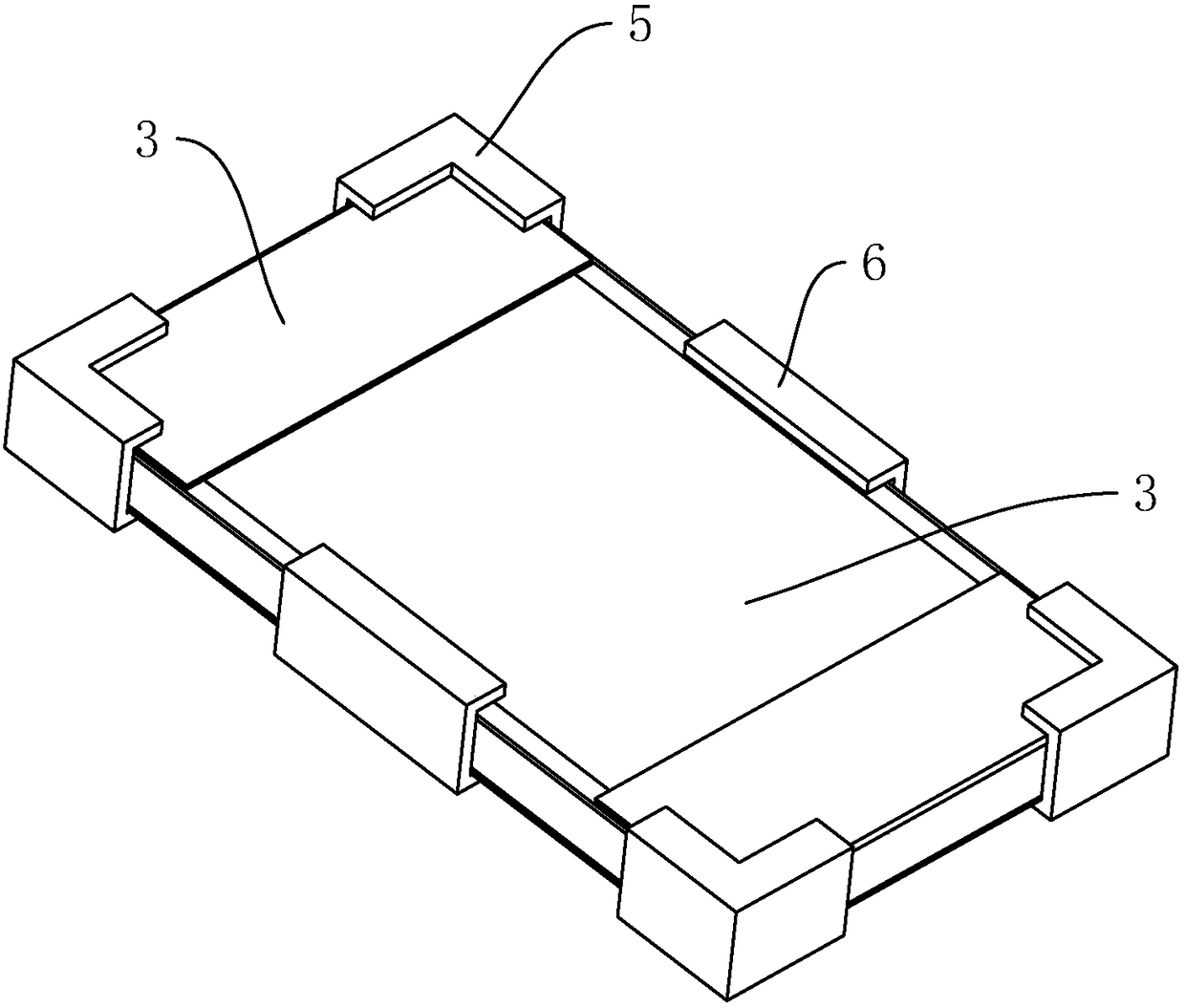

[0034] A, select the first carton 3 of the size of the glass 1 that meets the needs of packaging, the length and width of the first carton 3 are greater than the length and width of the glass 1, so that enough space can be left when the glass 1 is packed into the first carton 3; B. Lay a layer of shock-absorbing plate 2 on the bottom surface of the first carton 3, lay the glass 1 on the shock-absorbing plate 2, cover the upper surface of the glass 1 with a layer of shock-absorbing plate 2, and connect the edge of the glass 1 with the first carton 3 to form a gap, and sprinkle a desiccant on the damping plate 2 at the same time. The desiccant here can be silicon dioxide, which can prevent the glass 1 and the damping plate 2 from being damp and moldy. Board 2 adopts EPE p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com